Air compressor waste heat conversion and utilization equipment

A technology of waste heat conversion and air compressor, which is applied in the direction of mechanical equipment, machine/engine, liquid variable capacity machinery, etc., can solve the problem of wasting resources, and achieve the effect of saving resources, protecting the environment and protecting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

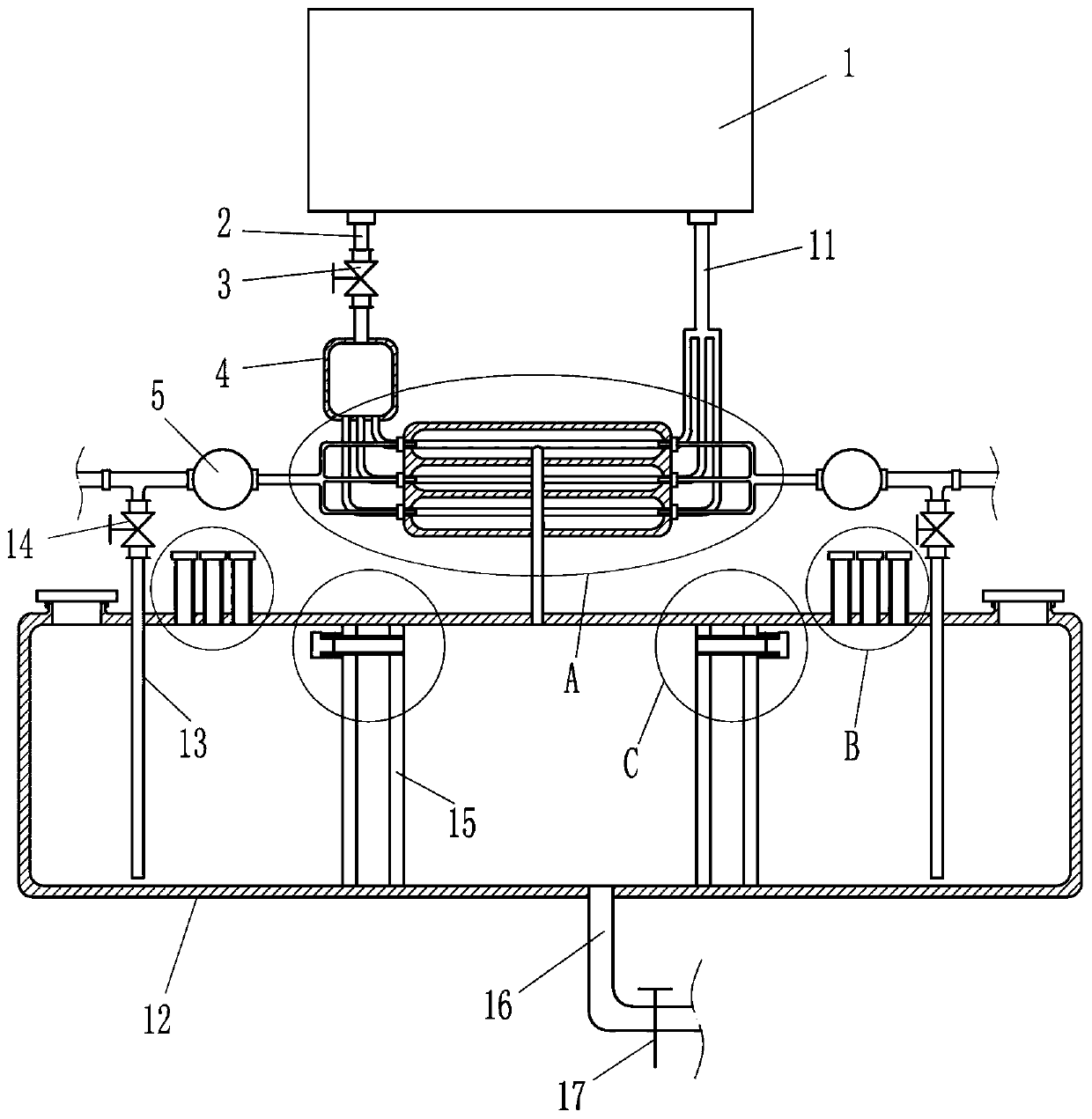

[0018] Such as figure 1 and 2 As shown, an air compressor waste heat conversion and utilization equipment includes an air compressor 1, an oil outlet pipe 2, a first battery valve 3, an oil circuit cooling component, an oil inlet pipe 11 and a water resource recycling component. An oil outlet pipe 2 and an oil inlet pipe 11 are installed, the first battery valve 3 is installed on the oil outlet pipe 2, and an oil circuit cooling component for cooling the oil circuit through water cooling is installed between the oil outlet pipe 2 and the oil inlet pipe 11, the oil circuit cooling A water resource reuse component is installed below the component.

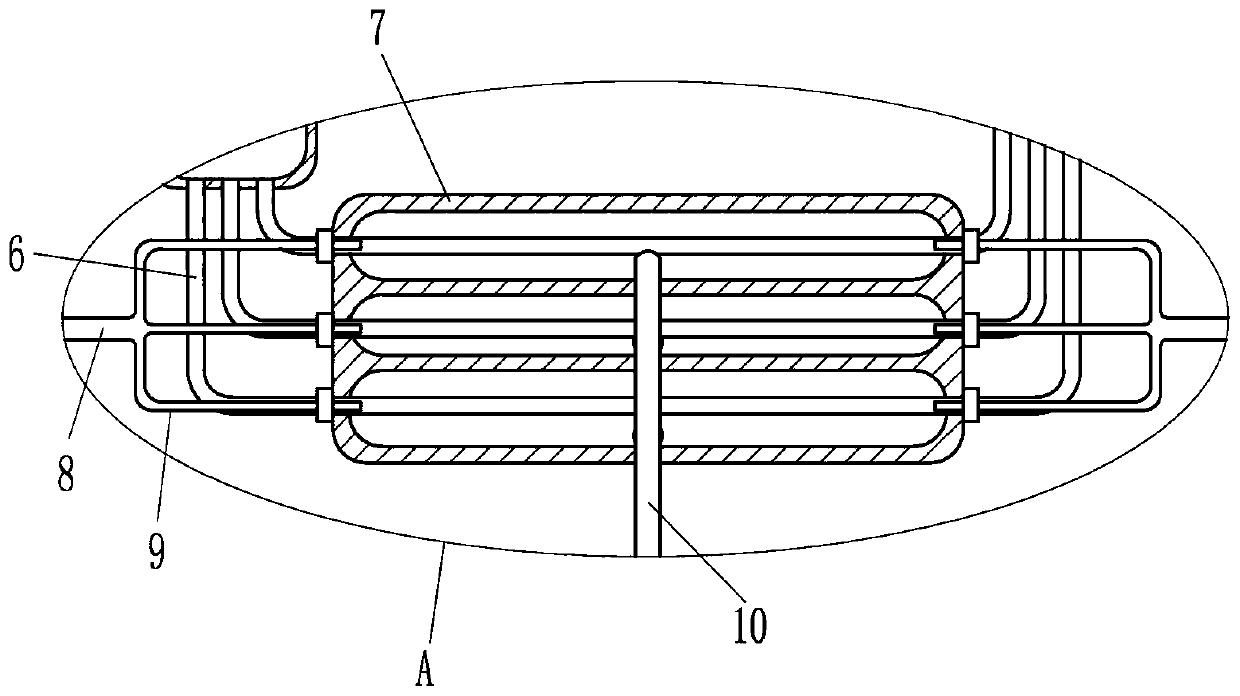

[0019] Such as figure 1 and 2 As shown, the oil circuit cooling components include a distribution frame 4, a water pump 5, an oil distribution pipe 6, a cooling box 7, a main water pipe 8, a water distribution pipe 9 and a water outlet pipe 10. The distribution frame 4 is installed at the outlet of the oil outlet pipe 2, and the b...

Embodiment 2

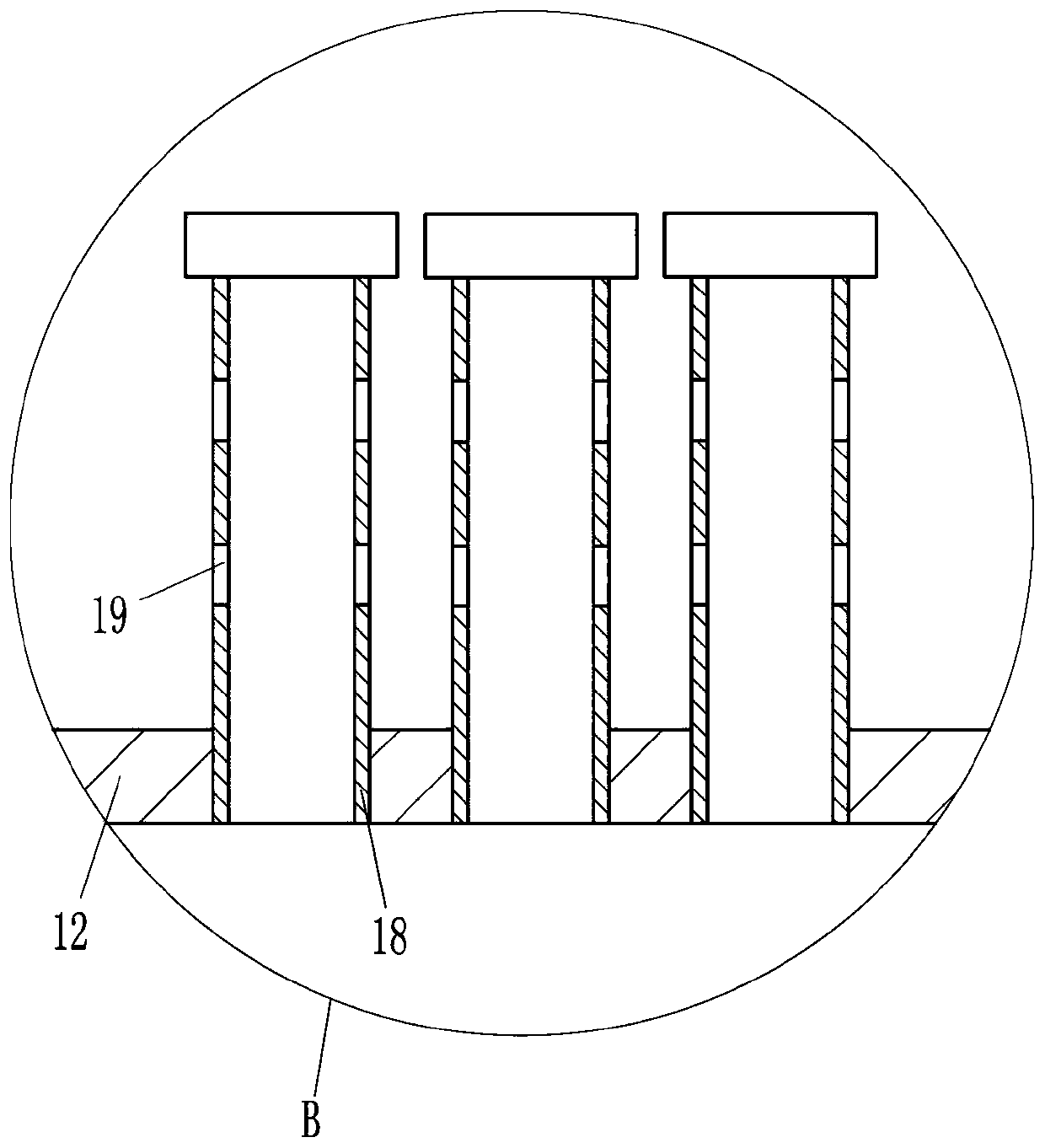

[0025] Such as figure 1 and 3 As shown, on the basis of Embodiment 1, in order to speed up the cooling of the water and use it in time, an air outlet pipe 18 is also included. Three air outlet pipes 18 are arranged on the left and right sides of the upper wall of the water tank 12, and there are two circles on the air outlet pipe 18. Cooling hole 19.

[0026] Such as figure 1 and 4 As shown, in order to prevent the loss of hot water heat, it also includes a moving plug 21 and a spring 22. The overflow pipe 151 has a water outlet hole 20 on the outside of the bottom. The overflow pipe 151 is equipped with a moving plug 21. The moving plug 21 can slide left and right. The moving plug 21 blocks the water outlet hole 20 , and a spring 22 is connected between the moving plug 21 and the overflow pipe 151 .

[0027] In the specific implementation manner of the above-mentioned embodiment, when water enters the water tank 12, it can dissipate heat through the cooling holes 19, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com