Stainless steel mesh for oil-water separation, preparation method and applications thereof

A stainless steel mesh, oil-water separation technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of high toxicity of raw materials, complicated processes, continuous operation or poor regeneration performance, and achieve broad industrial application prospects and Economic benefits, the preparation method is simple and easy to operate, and the effect of high-efficiency separation of oil-water mixture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The second aspect of the present invention provides a method for preparing a stainless steel mesh for oil-water separation, the method comprising: contacting the porous stainless steel mesh substrate with a solution containing alkyl mercaptans, so that the alkyl mercaptans grow in situ on the perforated stainless steel mesh substrate.

[0046] According to the preparation method of the stainless steel mesh for oil-water separation of the present invention, preferably, the aperture of the mesh of the porous stainless steel mesh substrate is 30-300 μm; more preferably, the aperture of the mesh of the porous stainless steel mesh substrate is 40-200 μm; further preferably, the mesh size of the porous stainless steel mesh base is 50-150 μm.

[0047] Specific examples of the mesh aperture of the porous stainless steel mesh base include: 30 μm, 35 μm, 40 μm, 50 μm, 55 μm, 60 μm, 65 μm, 70 μm, 80 μm, 90 μm, 100 μm, 110 μm, 120 μm, 130 μm, 140 μm, 150 μm , 180μm, 200μm, 220μm, ...

Embodiment 1

[0060] (1) Clean the base of 200-mesh stainless steel mesh (the pore size of the mesh is 75 μm) with acetone and absolute ethanol for 5 minutes, then take it out and dry it for later use;

[0061] (2) Weigh 12.1g (0.06mol) of 1-dodecanethiol, dissolve it in 200mL of 2-propanol, and prepare a 0.3mol / L solution of 1-dodecanethiol-2-propanol;

[0062] (3) Immerse the stainless steel mesh substrate in (1) in 0.3mol / L 1-dodecanethiol-2-propanol, and react at 25°C for 2h;

[0063] (4) Take out the stainless steel mesh base that has been reacted for 2h, and rinse the impurities adhered to the surface with deionized water, and dry to obtain superhydrophobic stainless steel mesh A1 (1-dodecane grown on the porous copper mesh substrate in situ The content of mercaptan is 4.7% by weight).

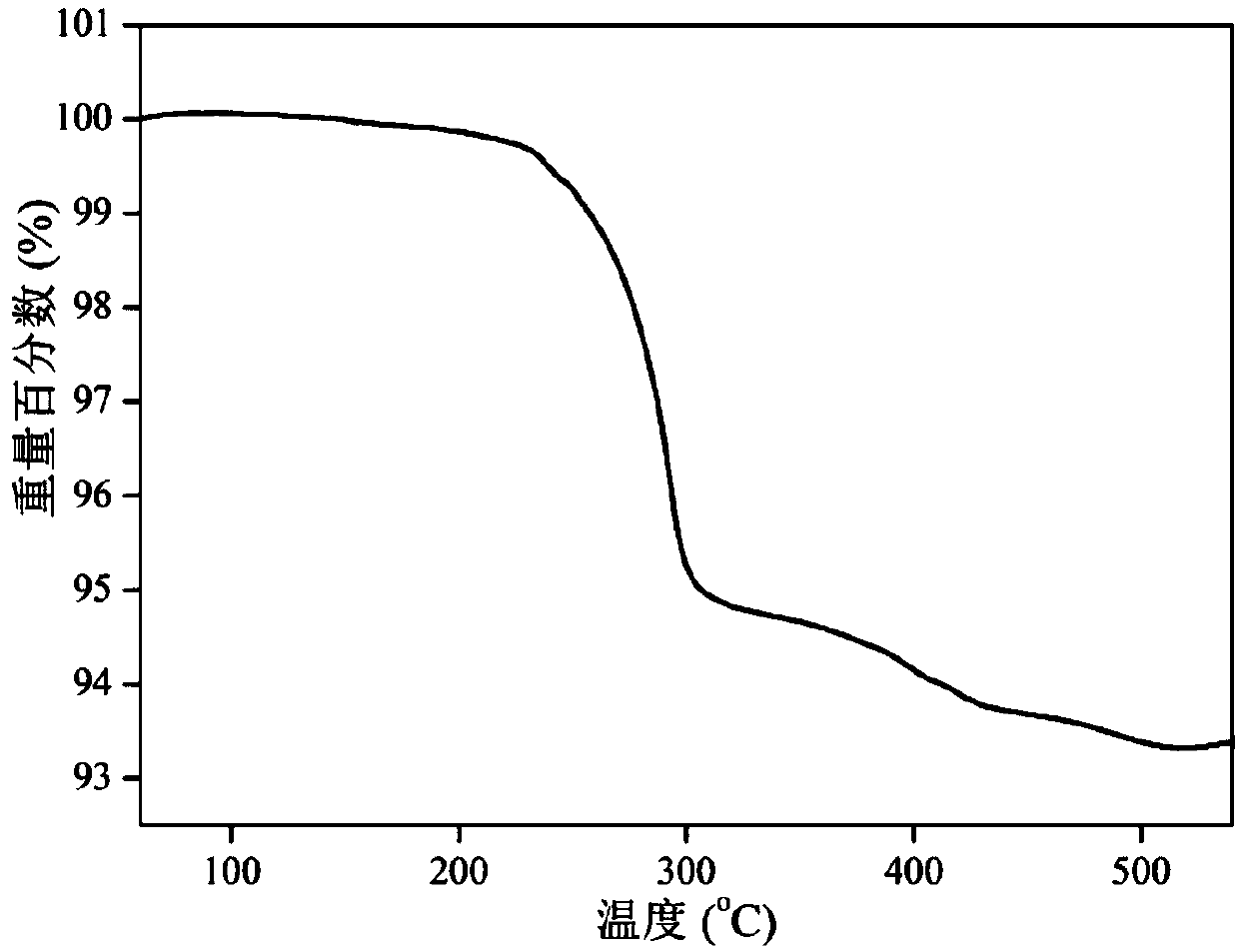

[0064] figure 1 This is the thermogravimetric (TG) picture of the treated stainless steel mesh. The thermogravimetric results show that there is a very obvious weight loss peak in the temperature ra...

Embodiment 2

[0068] (1) Clean the 300-mesh stainless steel mesh substrate (the aperture of the mesh is 50 μm) with acetone and absolute ethanol for 5 minutes, and then take it out and dry it for later use;

[0069] (2) Weigh 2.4g (0.02mol) of 1-hexanethiol, dissolve it in 200mL of methanol, and prepare a 0.1mol / L 1-hexanethiol-methanol solution;

[0070] (3) Immerse the stainless steel mesh substrate in (1) in 0.1mol / L 1-hexanethiol-methanol solution, and react at 25°C for 6h;

[0071] (4) Take out the stainless steel net base of reaction 6h, and rinse the impurities adhered to the surface with deionized water, and dry to obtain superhydrophobic stainless steel net A2 (1-hexanethiol grown on the porous copper net base in situ The content is 3.5% by weight).

[0072] According to the thermogravimetric analysis results of the superhydrophobic stainless steel mesh A2, the content of 1-hexanethiol grown on the porous copper mesh substrate in situ is 3.5% by weight.

[0073] According to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap