A kind of foam dedusting agent for construction site and preparation method thereof

A technology of dust remover and foam, which is applied in the field of foam dust remover for construction sites and its preparation, which can solve the problems of complex preparation process and unfavorable expansion of production, and achieve the effect of improving dust collection efficiency, long dust removal time and high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention also provides a preparation method of the foam dust remover, comprising the following steps: firstly add water to the container, heat to 40-50°C, add sodium lauryl sulfate, stir and dissolve; add coconut oil fatty acid diethanolamide, alkanes Glycoside, glycerin and sodium carboxymethylcellulose are stirred, mixed and dissolved to obtain a foam dust remover for construction sites.

[0021] The present invention has no special limitation on the mixing method, and the technical scheme of mechanical stirring or manual stirring well known to those skilled in the art can be adopted, and the purpose is to mix the reaction raw materials evenly.

Embodiment 1

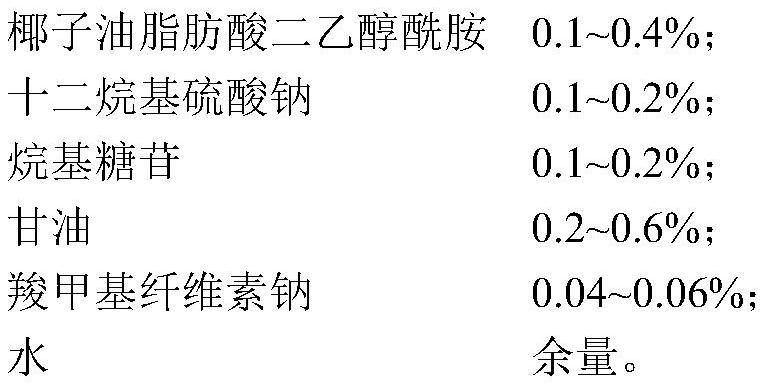

[0024] The foam dust remover is prepared by mixing the following components by weight percentage:

[0025]

[0026] Specifically, add 990.6 g of water to the container, heat it to 50° C., add 1 g of sodium lauryl sulfate for the calculated foam dust removal dose, stir and dissolve; then add 2 g of the calculated foam dust removal dose Coconut oil fatty acid diethanolamide, alkyl glucoside for calculating and preparing foam dust removal dosage 2g, glycerol for calculating and preparing foam dust removal dosage 4g and sodium carboxymethyl cellulose for calculating and preparing foam dust removal dosage 0.4g, stirring, mixing and dissolving to obtain foam dust remover . The obtained foam dedusting agent for the construction site was measured with a Roche foam meter to have a foaming ratio of 172 times. Put it in the foam dedusting device, spray and dedust the mine construction site, and control the spraying amount to 30mL / m 3 , Dust removal is completed after spraying. The ...

Embodiment 2

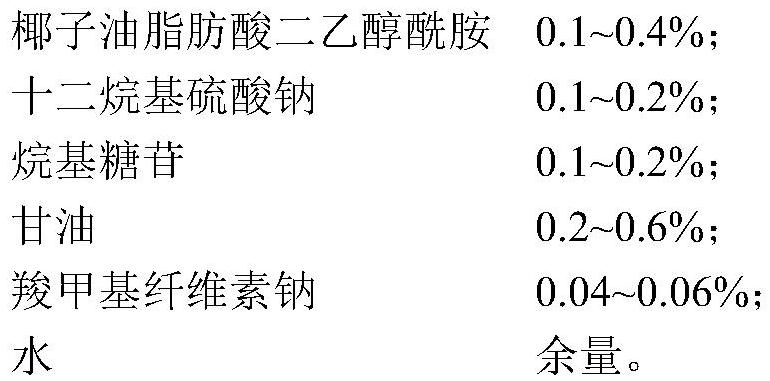

[0028] The foam dust remover is prepared by mixing the following components by weight percentage:

[0029]

[0030]

[0031] Specifically, add 993.5 g of water to the container, heat it to 50°C, add 2 g of sodium lauryl sulfate, stir and dissolve; then add 1 g of the calculated foam dust removal dose in turn Coconut oil fatty acid diethanolamide, alkyl glycosides with 1g of calculated and prepared foam dust removal dosage, 2g of glycerin with calculated and prepared foam dust removal dosage and 0.5g of sodium carboxymethyl cellulose, mixed and dissolved to obtain construction site foam dust remover. The obtained foam dedusting agent was measured with a Roche foam meter to have a foaming ratio of 158 times. Put it in the foam dedusting device, spray and dedust the mine construction site, and control the spraying amount to 30mL / m 3 , Dust removal is completed after spraying. The CCHG1000 direct-reading dust concentration measuring instrument is used to measure the dust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com