Method for cutting thermal simulation calculation in brittle material cutting machining

A brittle material, cutting technology, applied in the research field of thermal-mechanical coupling modeling of cutting, which can solve the problems of neglecting heat and unable to truly reflect the influence of cutting heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with accompanying drawing.

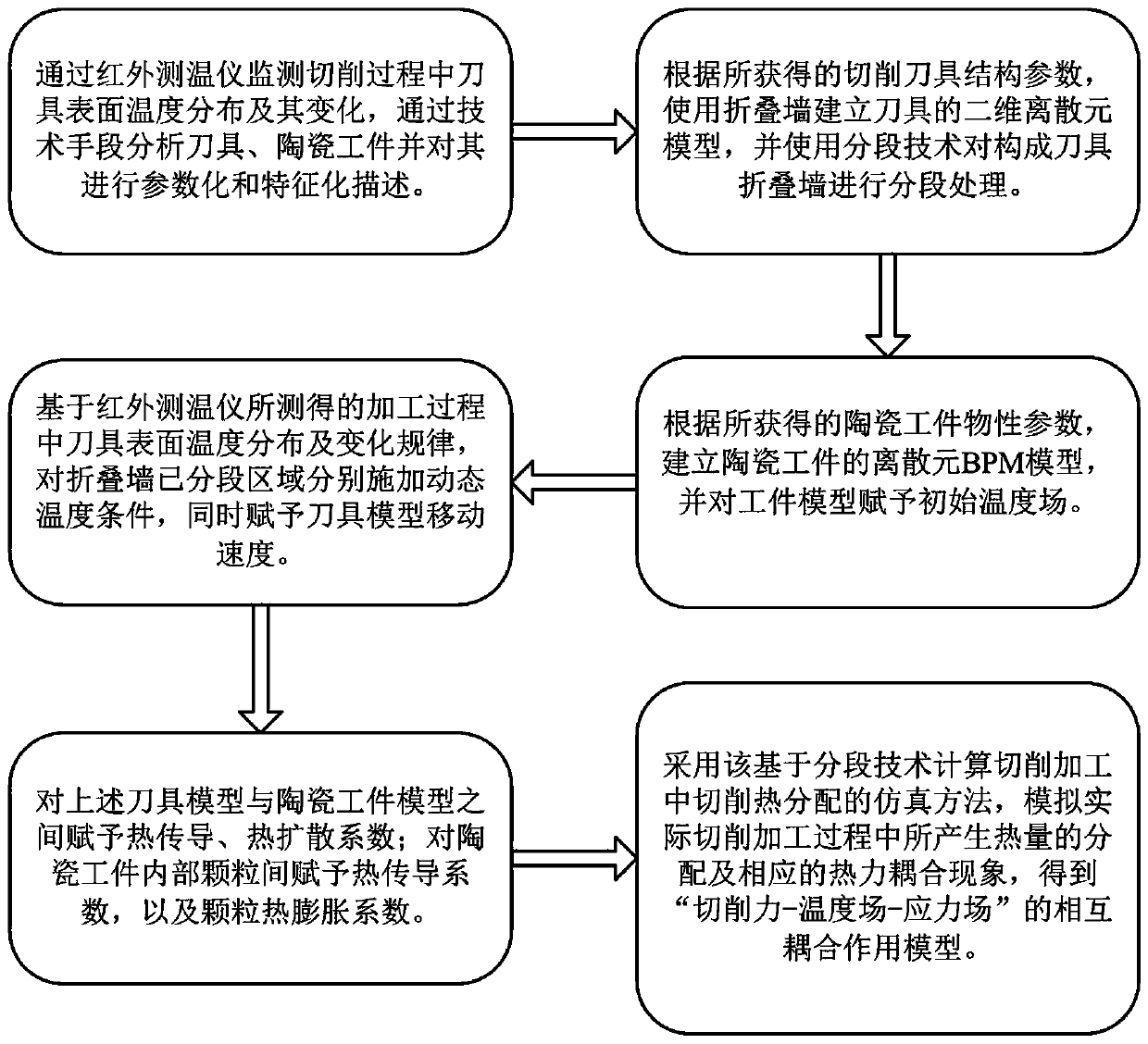

[0057] A method for simulation calculation of cutting heat in the cutting process of brittle materials. The example brittle material is SiC ceramic material, and the example software is PFC5.0 2D, including the following steps:

[0058] (1) Analyze the size, shape and density distribution of common defects (such as microcracks and holes) on the surface / subsurface of SiC ceramic material workpieces by technical means (such as ultrasonic scanning microscope), and perform parametric and characteristic descriptions;

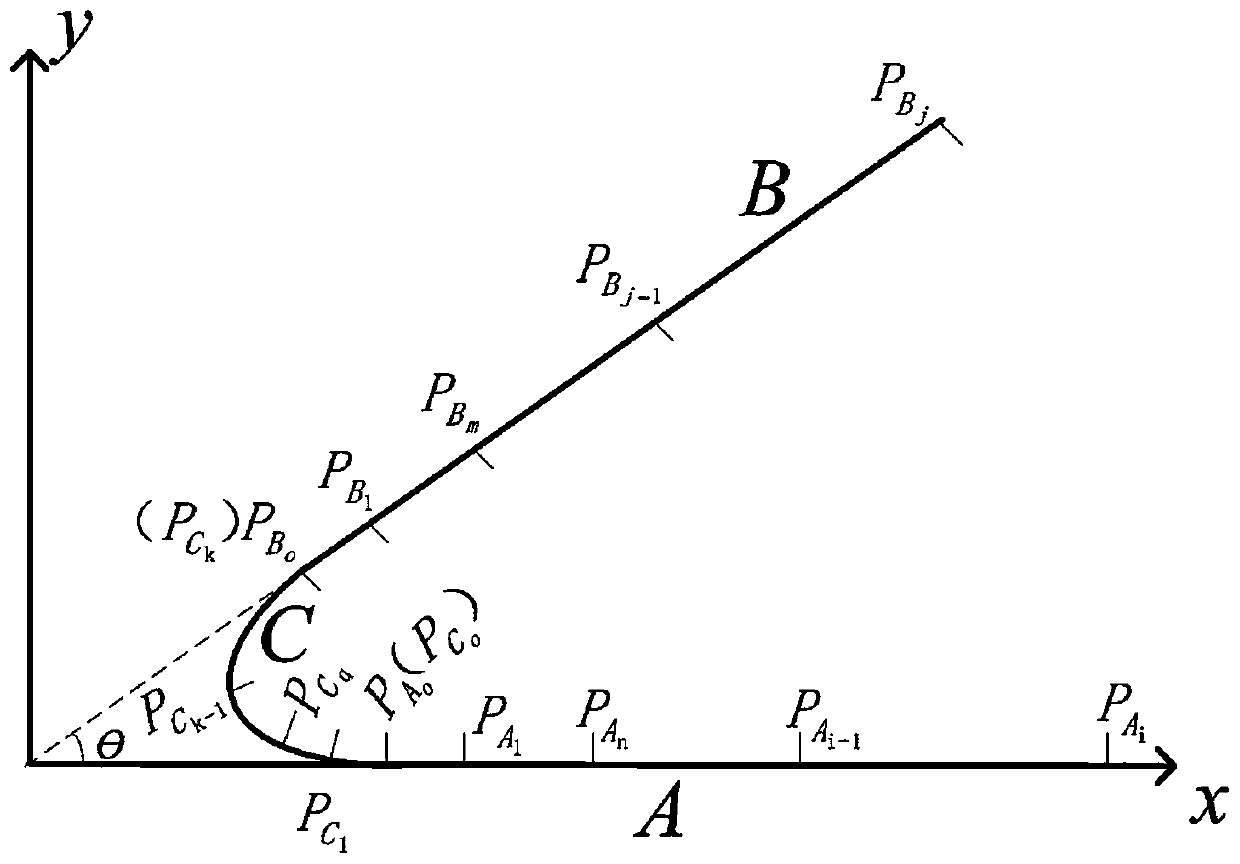

[0059] (2) Obtain the geometric characteristic parameters of the cutting tool through technical means, including the tool rake angle γ 0 , Tool relief angle α 0 And the radius of the tool nose arc r 0 etc.; in this example, tool rake angle γ 0 =20°; Tool relief angle α 0 =30°; tool nose arc radius r 0 =0.2mm;

[0060] (3) In the PFC5.0 2D software, use the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com