Intelligent manufacturing device capable of automatically removing dusts

A technology of intelligent manufacturing and automatic dust removal, applied in transportation and packaging, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of easy leakage of ecological environment, small degree of sealing, and slight effect, and achieve low operating noise and sealing Good performance, anti-backflow pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention.

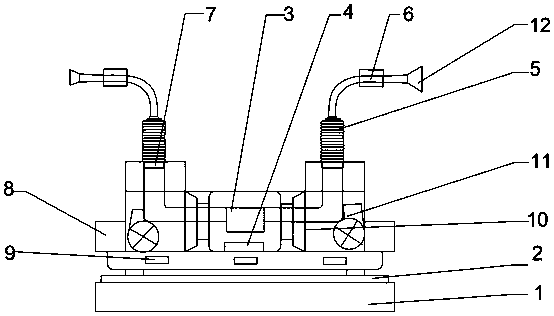

[0021] Such as figure 1 Shown is an intelligent manufacturing equipment that can automatically remove dust, including: support base 1, slide rail 2, collection box 3, dust outlet 4, pipe 5, bracket 6, filter screen 7, motor unit 8, shock-absorbing base 9, Seal the sound-absorbing pad 10, the centrifugal blower 11 and the guide port 12.

[0022] Wherein, the support base 1 bottom is provided with roller, and the other side of support base 1 is fixedly installed with slide rail 2; side; the executive mechanism is provided with a protective shell and the inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com