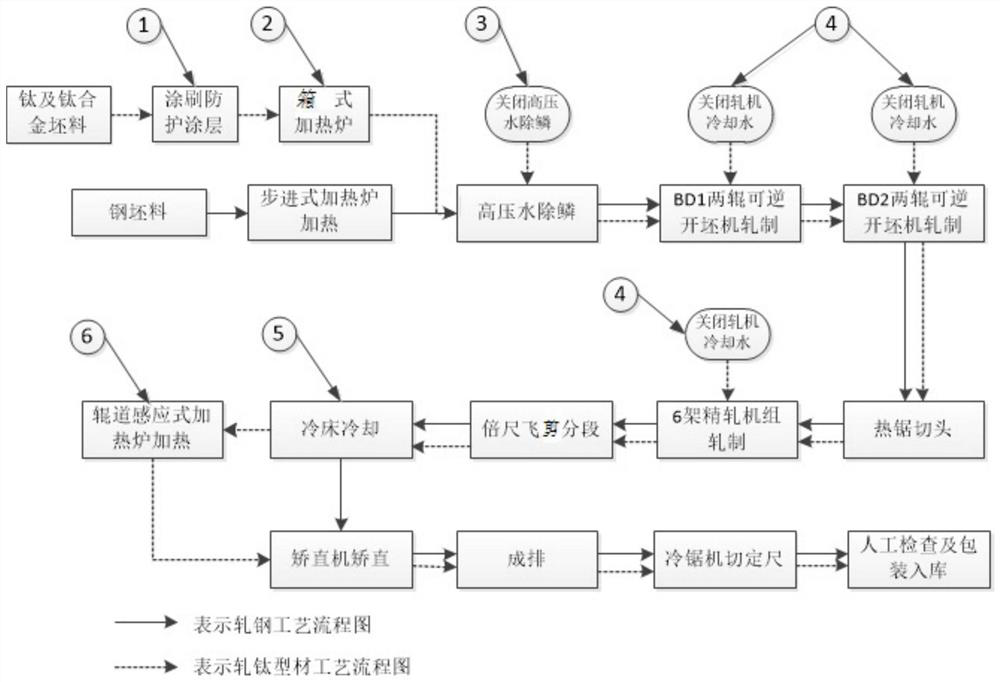

A kind of collinear production method of titanium and titanium alloy profile and profile steel

A production method and technology for titanium alloys, which are applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of cooling water control in rolling mills without considering the heating system of titanium and steel materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Titanium H-shaped bar is rolled on the small and medium-sized section steel production line, the grade is TA1, and the specification is H100×100×6×8. The production process is as follows:

[0043] 1) Billet preparation: Calculate the required billet length according to the specifications and length of the rolled product, and the surface quality of the billet should meet the production requirements;

[0044] 2) brushing protective coating: brushing protective coating on the surface of the blank;

[0045] 3) Heating: use the roller table to transport the billet to the box-type resistance heating furnace for heating, the heating temperature is 930°C, and the holding time is 160min, and then the billet is conveyed to the rolling mill area by the conveying roller table.

[0046] 4) Rolling line preheating: Before rolling titanium materials, roll 5 hot-rolled H-beams of the same specification to preheat the rolling line and adjust the specifications and dimensions of the hot-...

Embodiment 2

[0056] Rolling titanium H-shaped bar on the small and medium-sized section steel production line, the grade is TC4, and the specification is H150×150×7×10. The production process is as follows:

[0057] 1) Billet preparation: Calculate the required billet length according to the specifications and length of the rolled product, and the surface quality of the billet should meet the production requirements;

[0058] 2) brushing protective coating: brushing protective coating on the surface of the blank;

[0059] 3) Heating: The billet is transported to a box-type resistance heating furnace for heating with a roller table. The heating temperature is 1100°C and the holding time is 150 minutes. Then, the billet is transported to the rolling mill area by the conveying roller table.

[0060] 4) Rolling line preheating: Before rolling titanium materials, roll 5 hot-rolled H-beams of the same specification to preheat the rolling line and adjust the specifications and dimensions of the h...

Embodiment 3

[0070] Titanium channel profiles are rolled on the small and medium-sized section steel production line, the grade is TA1, and the specification is [80×43×5.0×8.0]. The production process is as follows:

[0071] 1) Billet preparation: Calculate the required billet length according to the specifications and length of the rolled product, and the surface quality of the billet should meet the production requirements;

[0072] 2) brushing protective coating: brushing protective coating on the surface of the blank;

[0073] 3) Heating: use the roller table to transport the billet to the box-type resistance heating furnace for heating, the heating temperature is 930°C, and the holding time is 160min, and then the billet is conveyed to the rolling mill area by the conveying roller table.

[0074] 4) Rolling line preheating: Before rolling titanium materials, roll 5 hot-rolled channel steels of the same specification to preheat the rolling line and adjust the specifications and dimensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com