Dipped canvas fabric structure in three-dimensional structure for heavy-duty conveyor belt and production process thereof

A three-dimensional structure, dipped canvas technology, applied in the direction of fabric, textile, fiber processing, etc., can solve the problems of poor ability to pass through the roller, poor softness of the conveyor belt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

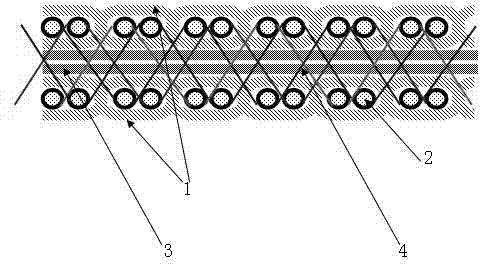

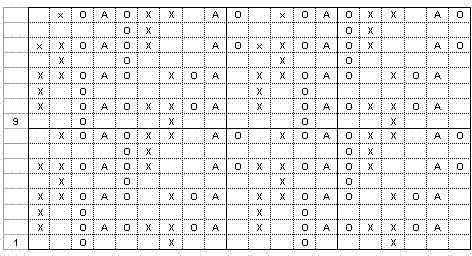

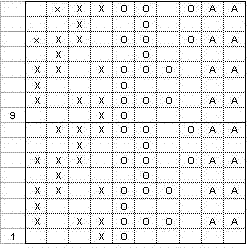

[0076] Embodiments of the present invention: the three-dimensional structure dipped canvas fabric structure that the heavy-duty conveyor belt of the present invention is used is: the surface ground warp yarn 1 of plain weave structure and the weft yarn 2 interwoven with the surface ground warp yarn 1 of the upper layer and the bottom layer, and the middle layer is straight The straight warp yarn 3 of the warp structure, the binding warp yarn 4 is connected to the weft yarn 2, and the upper layer, the middle layer, the bottom layer and the binding warp yarn form a three-dimensional structure. Wherein the straight warp yarn 3 is two layers. as attached figure 1 shown.

[0077] The fabric structure of the three-dimensional structure described in the present invention is: the composite of straight warp and straight weft, double weft and flat plain structure. The upper layer (surface layer) is a plain weave structure, the bottom layer is also a plain weave structure, and the mid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com