A New Adjustable Experimental Cartilage Planer

An adjustable and experimental technology, which is applied in the field of medical experiment sampling tools, can solve the problems of low purity of obtained samples, waste of experimental samples, laborious cutting of samples with scalpels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

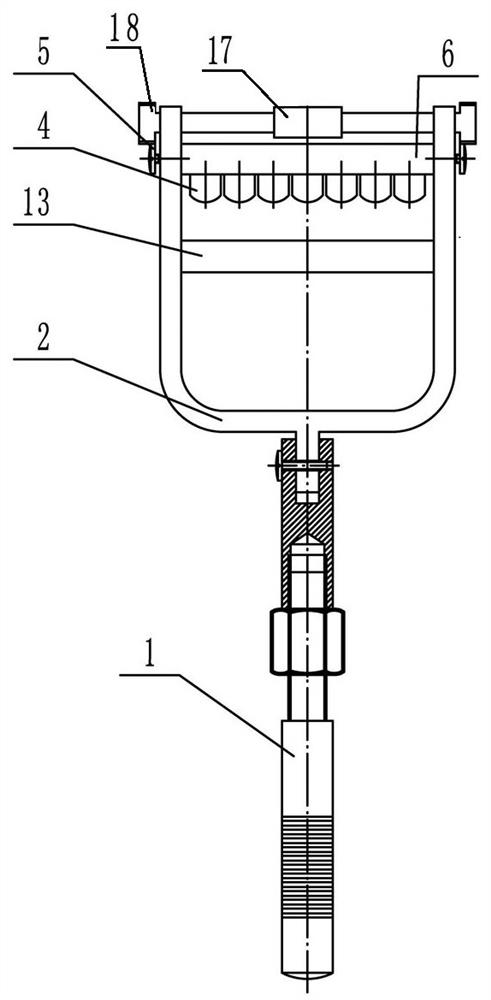

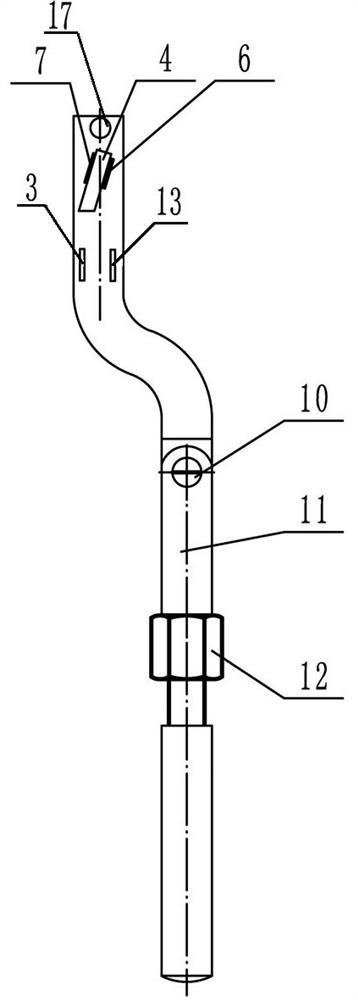

[0033] Embodiment 1, the present invention is a new type of adjustable experimental cartilage planer, comprising a knife bar 11 and a knife holder 2 arranged on the knife bar 11, characterized in that, refer to figure 1 , the knife rest 2 is U-shaped and one end without opening is connected to the knife bar 11, and the open end of the knife rest 2 is fixedly connected with an upper splint 6, and the upper splint 6 is provided with a The lower splint 7, between the lower splint 7 and the upper splint 6 are provided with a number of blades 4 evenly distributed along the upper splint 6, wherein the upper splint 6 provides a fixed basis for the blade 4 groups, specifically, it can be on the upper splint 6. Set up a chute towards the side of the lower splint 7, so that the blade 4 is slidably connected in the chute. The lower splint 7 is used to provide a limit for the flipping of the blade 4, preventing the blade 4 from driving the upper splint 6 to turn over when it is stressed, a...

Embodiment 2

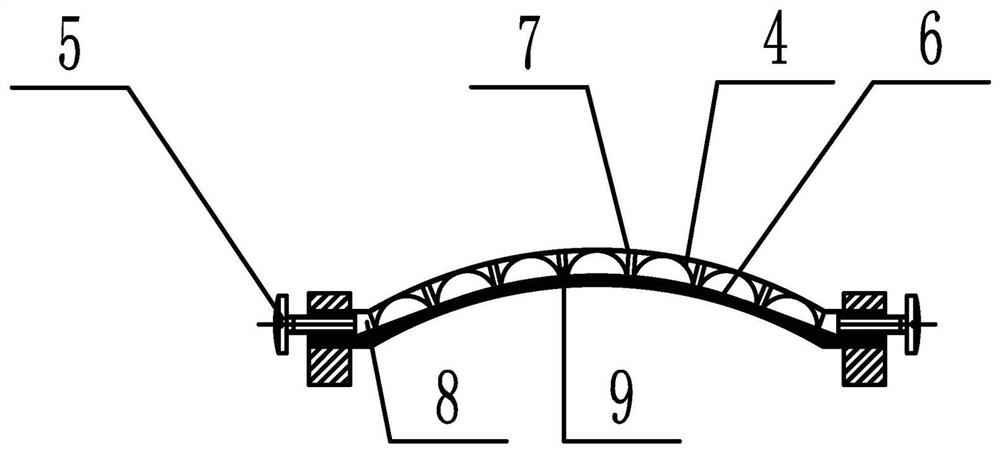

[0040] Embodiment 2, on the basis of Embodiment 1, the upper splint 6 and the lower splint 7 are 18-20 stainless steel metal sheets with different thicknesses, that is, stainless steel supported by +18% chromium + 10% nickel, which is more durable and more durable. Corrosion resistance and no metal ion precipitation at all, more suitable for medical environment, the same material has good elastic deformation ability, when the slider 8 moves to both sides, it can quickly return to the original state, the thickness of the upper splint 6 Greater than the thickness of the lower clamping plate 7, this setting can make the deformability of the upper clamping plate 6 smaller than that of the lower clamping plate 7, so that the distance between the upper clamping plate 6 and the lower clamping plate 7 can be kept consistent, and the 4 groups of blades can realize different bending arcs.

Embodiment 3

[0041] Embodiment 3, on the basis of Embodiment 1, the adjustment mechanism includes an upper adjustment bolt 5 passing through the knife holder 2;

[0042] Both sides of the open end of the knife rest 2 are provided with threaded holes for the knife rest 2, and the two upper adjusting bolts 5 are respectively placed in the corresponding threaded holes of the knife rest 2 and threaded, and one end of the two upper adjusting bolts 5 is respectively connected to the corresponding The sliding block 8 is contacted and connected. In this embodiment, the user rotates the two upper adjusting bolts 5 respectively to slide against the sliding block 8 during specific use in this embodiment, so that the 4 groups of blades are pushed into arcs of different shapes, so as to Adapt to different specimens.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com