Printing device for packaging box production

A printing device and packaging box technology, applied in printing, printing machines, rotary printing machines, etc., can solve problems such as blurred printing, achieve the effects of preventing deviation, increasing friction, and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

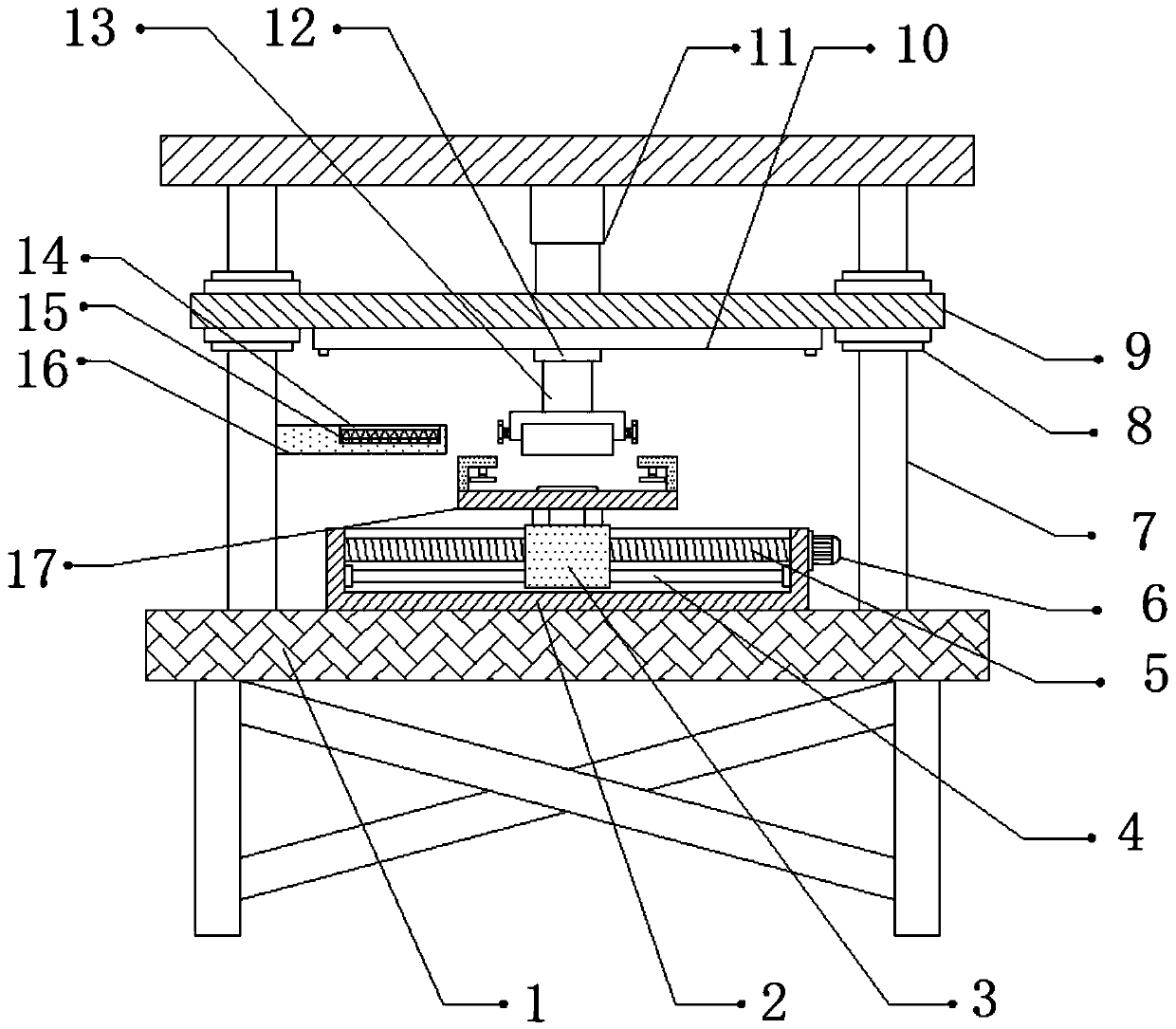

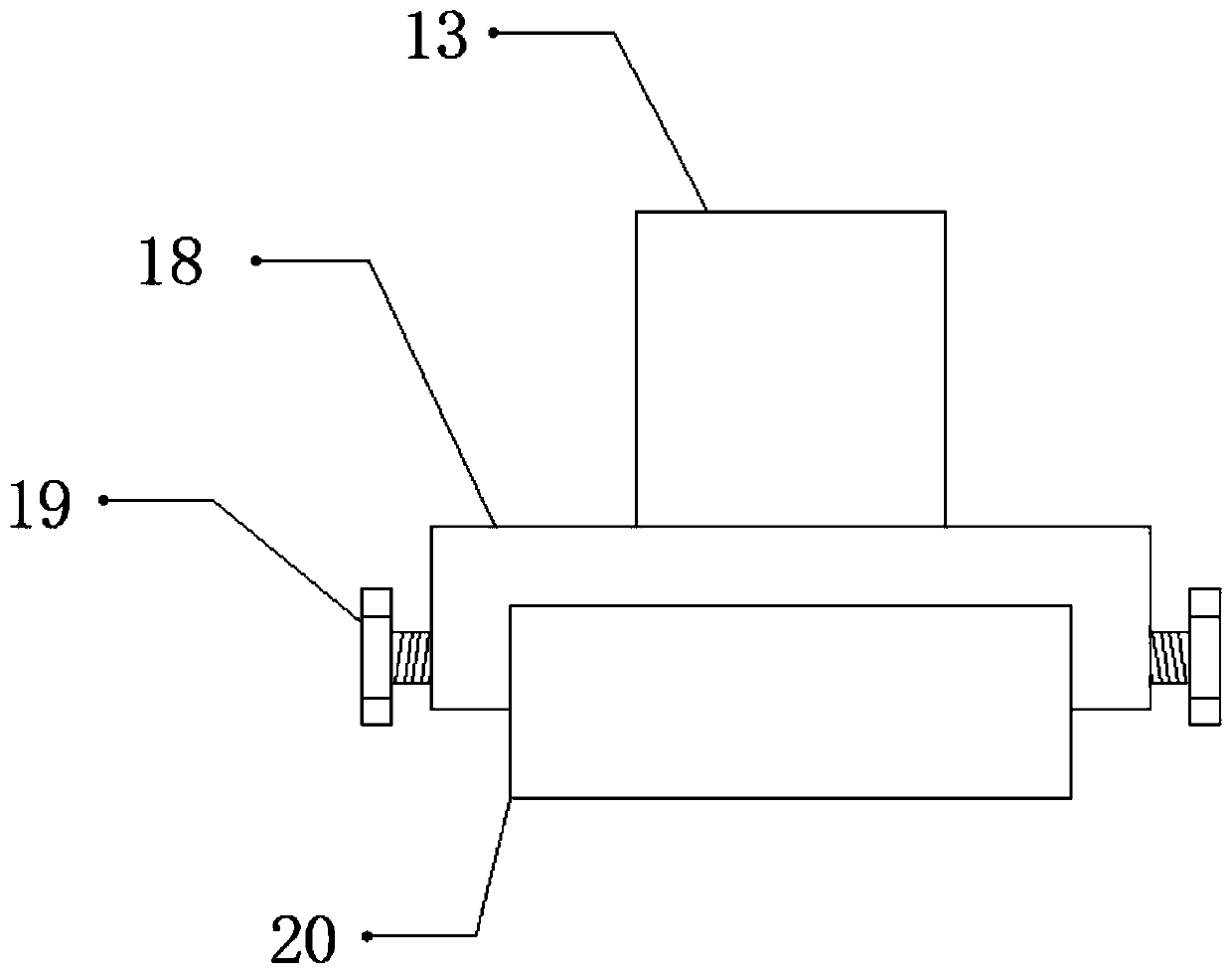

[0032] refer to Figure 1-3 , a printing device for packaging box production, comprising a fixing base 1, both sides of the top outer wall of the fixing base 1 are connected with fixing rods 7 by bolts, and the top outer walls of the two fixing rods 7 are connected with a top plate by bolts, and the top of the top plate The outer wall of the bottom is connected with the electric telescopic rod 11 by bolts, and the outer wall of the bottom of the electric telescopic rod 11 is connected with the fixed plate 9 by bolts, the outer wall of the bottom of the fixed plate 9 is connected with the electric slide rail 10 by bolts, and the inner wall of the electric slide rail 10 slides Slide block 12 is connected, the bottom outer wall of slide block 12 is connected with fixed shaft 13 by bolt, and the bottom outer wall of fixed shaft 13 is connected with fixed frame 18 by bolt, and the inner wall of fixed frame 18 is provided with template 20, and the two sides of fixed frame 18 The sid...

Embodiment 2

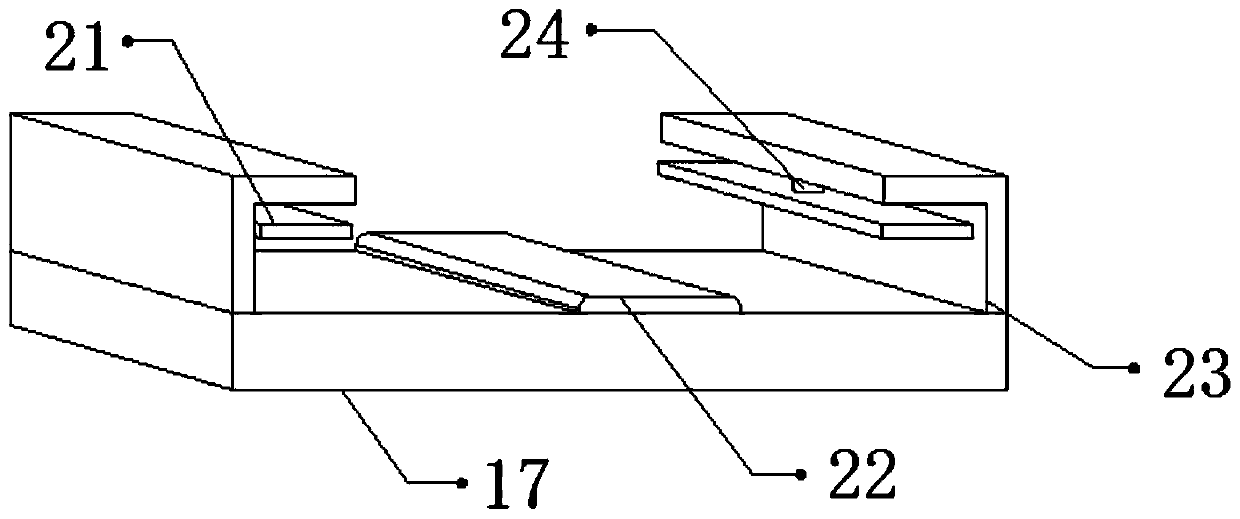

[0043] refer to Figure 4-5 , a printing device for packaging box production. Compared with Embodiment 1, the outer walls of the bottom of the two splints 21 are provided with a plurality of equidistant ribs 25, which can increase the distance between the splint 21 and the packaging box. The frictional force prevents the movement between the packaging box and the splint 21 due to vibration, thereby causing deviation to the printing of the packaging box.

[0044] Working principle: when in use, place the packaging box that needs to be printed on the support plate 17, start the hydraulic rod 24, and the hydraulic rod 24 will drive the splint 21 to move, so that the splint 21 fixes the two sides of the packaging box. The rib 25 can increase the friction between the splint 21 and the packing box, prevent the packing box from moving between the splint 21 due to vibration, thereby causing deviation to the printing of the packing box, and the raised plate 22 highlights the part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com