Pile bottom grouting cavity and use method, and poured pile body and construction method of poured pile body

A technology of grouting cavity and cast-in-place pile, which is applied in the direction of sheet pile wall, foundation structure engineering, building, etc. It can solve problems such as grouting pipe blockage, improve the bearing capacity of pile ends, ensure the effect of compaction, and ensure the smooth flow of pipelines Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

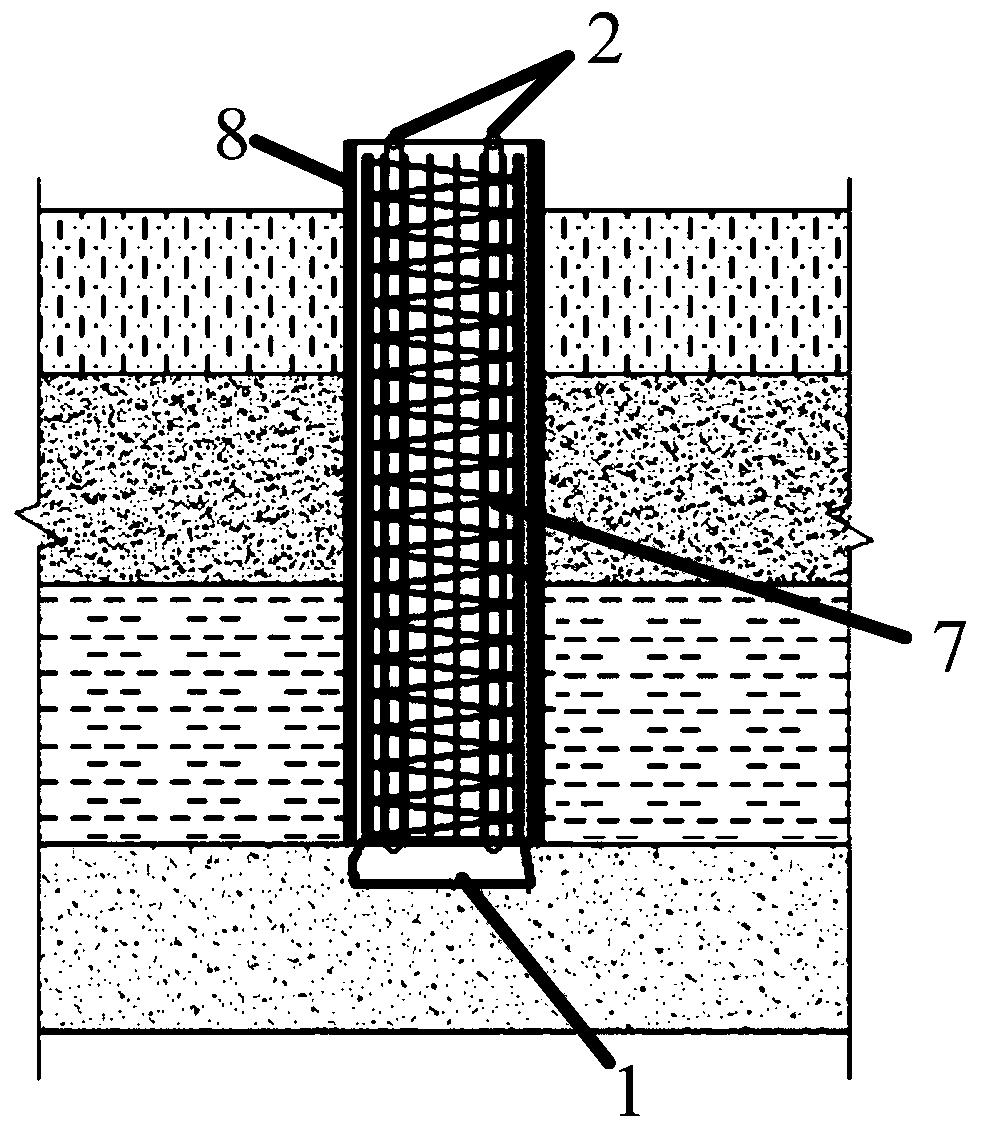

[0070] A kind of cast-in-place pile body provided in this embodiment, such as Figure 6 shown, including:

[0071] Pile bottom grouting cavity;

[0072] Reinforcement cage 7 is connected with the grouting cavity at the bottom of the pile, and the grouting pipe 2 is fixedly connected with the reinforcement cage 7 by binding. The reinforcement cage 7 is also fixed with a pile side grouting pipe 10. The pile The grouting hole of the side grouting pipe 10 is arranged at a position close to the grouting capsule 1, grouting towards the pile side formation;

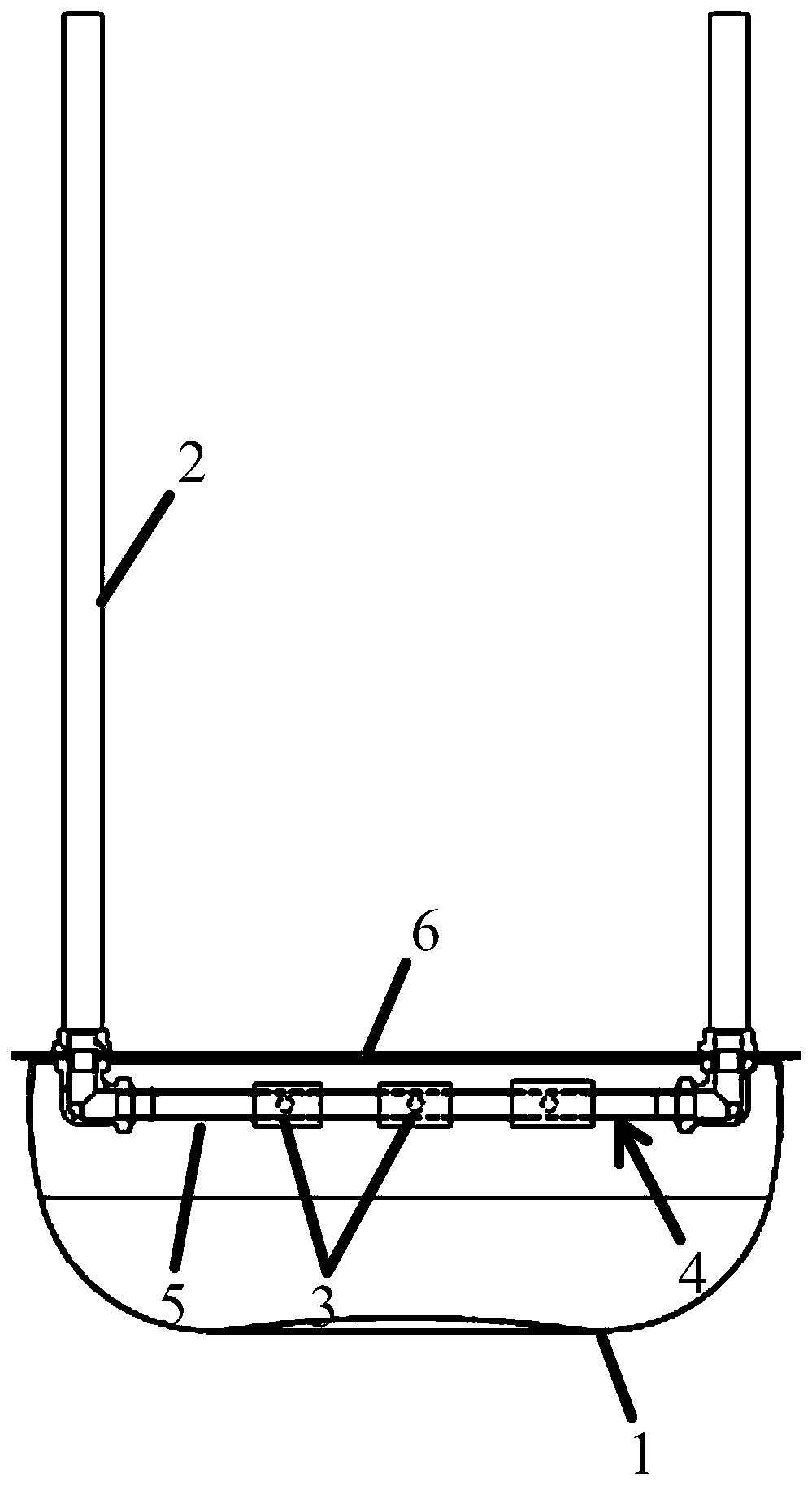

[0073] The pile bottom grouting cavity in this application, such as figure 1 shown, which includes:

[0074] The grouting capsule 1 is made of rubber, and has an expanded state filled with grout to carry the pile body, and a contracted state with a hollow interior;

[0075] The grouting pipe 2 communicates with the inner cavity of the grouting capsule 1, and injects grout into the grouting capsule 1. The grouting tube 2 has ...

Embodiment 2

[0096] The difference between this embodiment and embodiment 1 is that the construction method of the cast-in-situ pile body comprises the following steps:

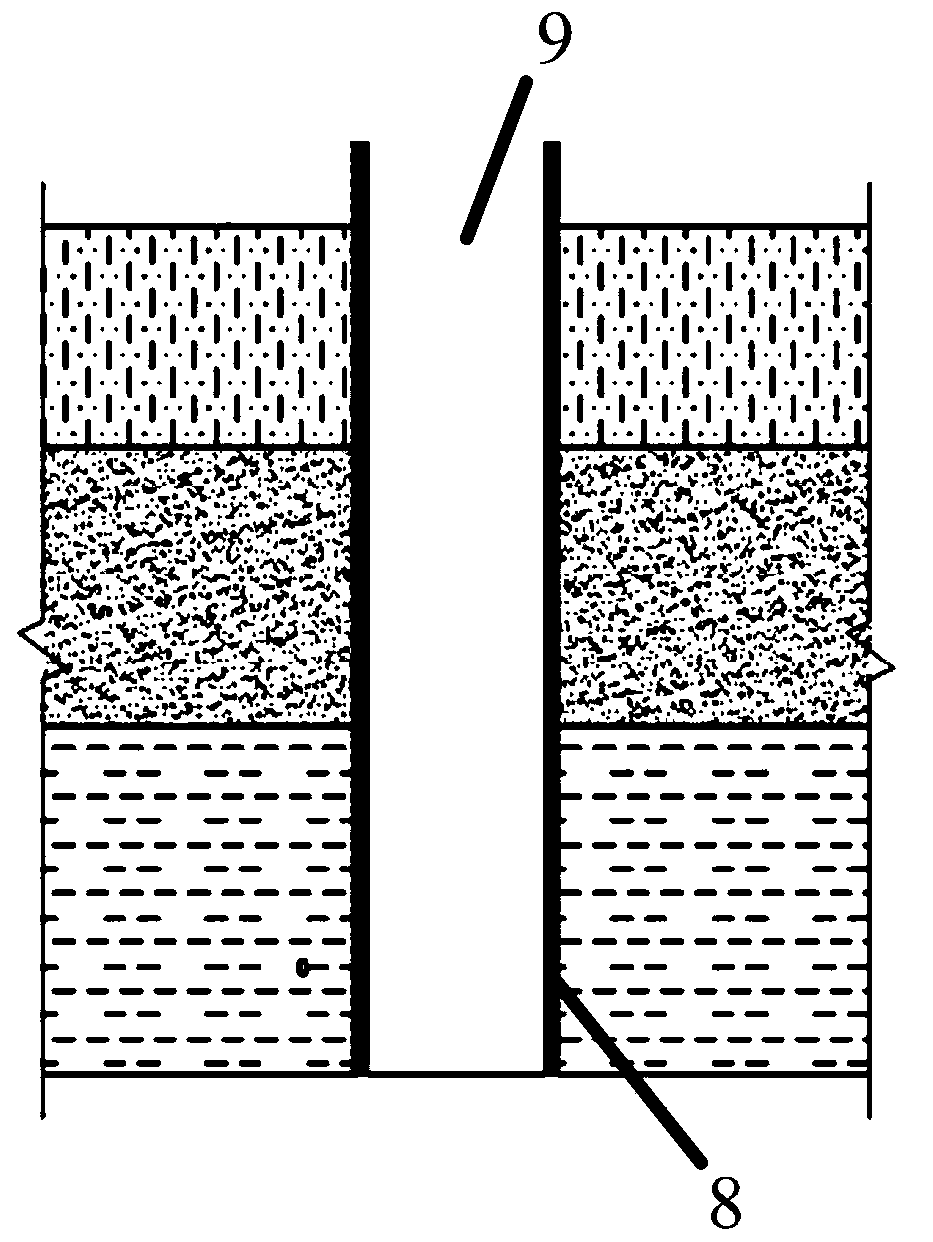

[0097] S1, forming a hole by artificial wall-retaining method to form a hole 9 with an artificial wall;

[0098] S2, sinking the reinforcement cage 7 with the pile bottom grouting cavity installed at the lower end to the bottom of the hole 9;

[0099] S3, pouring concrete into the hole 9, so that the reinforcement cage 7 and the inner cavity wall of the hole 9 are fixed together;

[0100] S4, injecting grout into the grouting capsule 1 to form a pile bottom expansion head;

[0101] The following problems can be effectively prevented by using the artificial retaining wall to form a hole with the cast-in-place pile body: when the cast-in-situ pile body is formed with a mud retaining wall, the reinforcement cage with the fixing plate 6 is stuck in the drilled hole when the reinforcement cage is lowered to the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com