Feeding device of IC card slot milling machine

A groove milling machine and conveying device technology, applied in milling machine equipment, milling machine equipment details, metal processing and other directions, can solve the problems of small IC card capacity, IC card feeding multiple, IC card process waiting, etc. , High card issuance efficiency, and the effect of increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

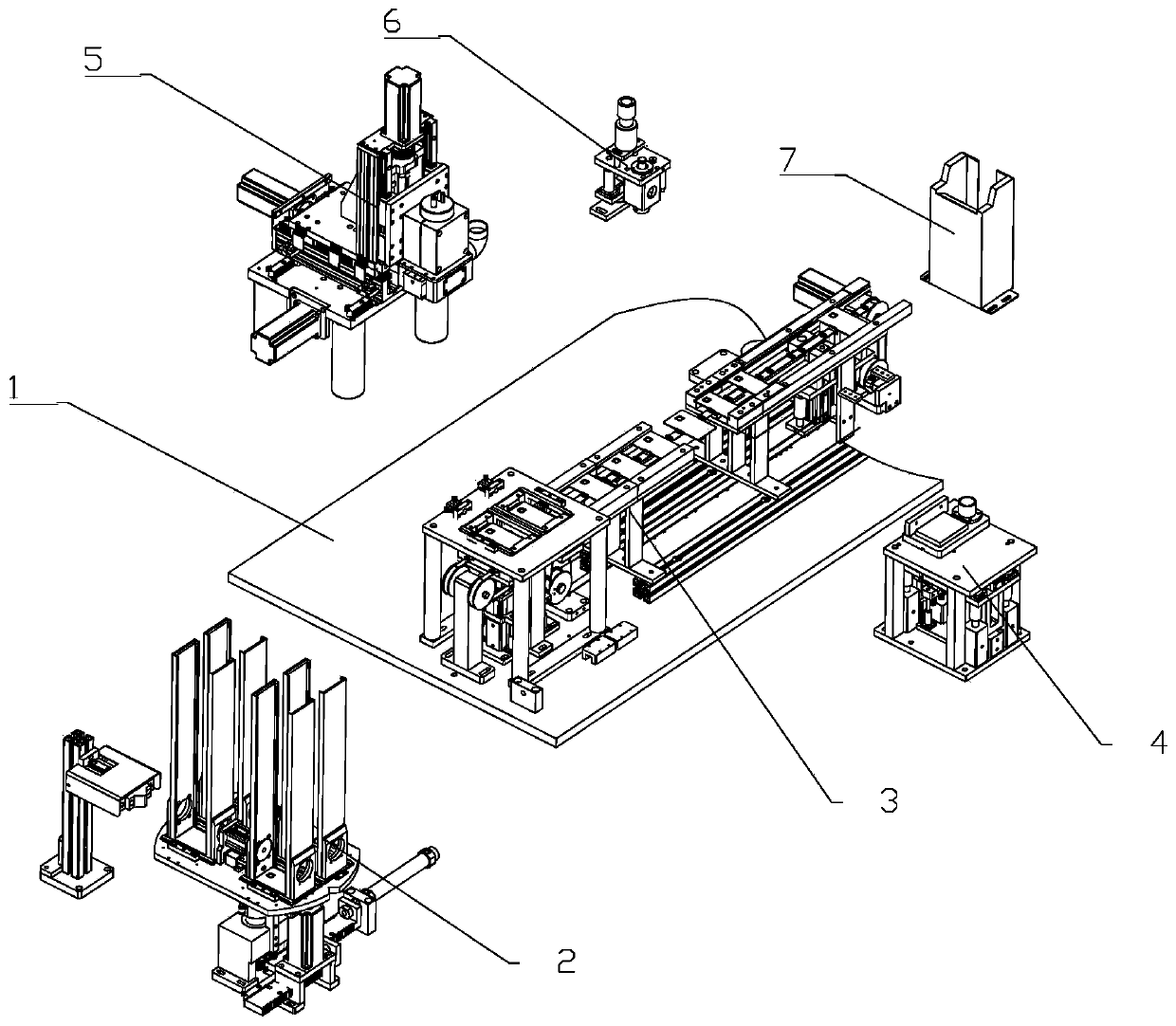

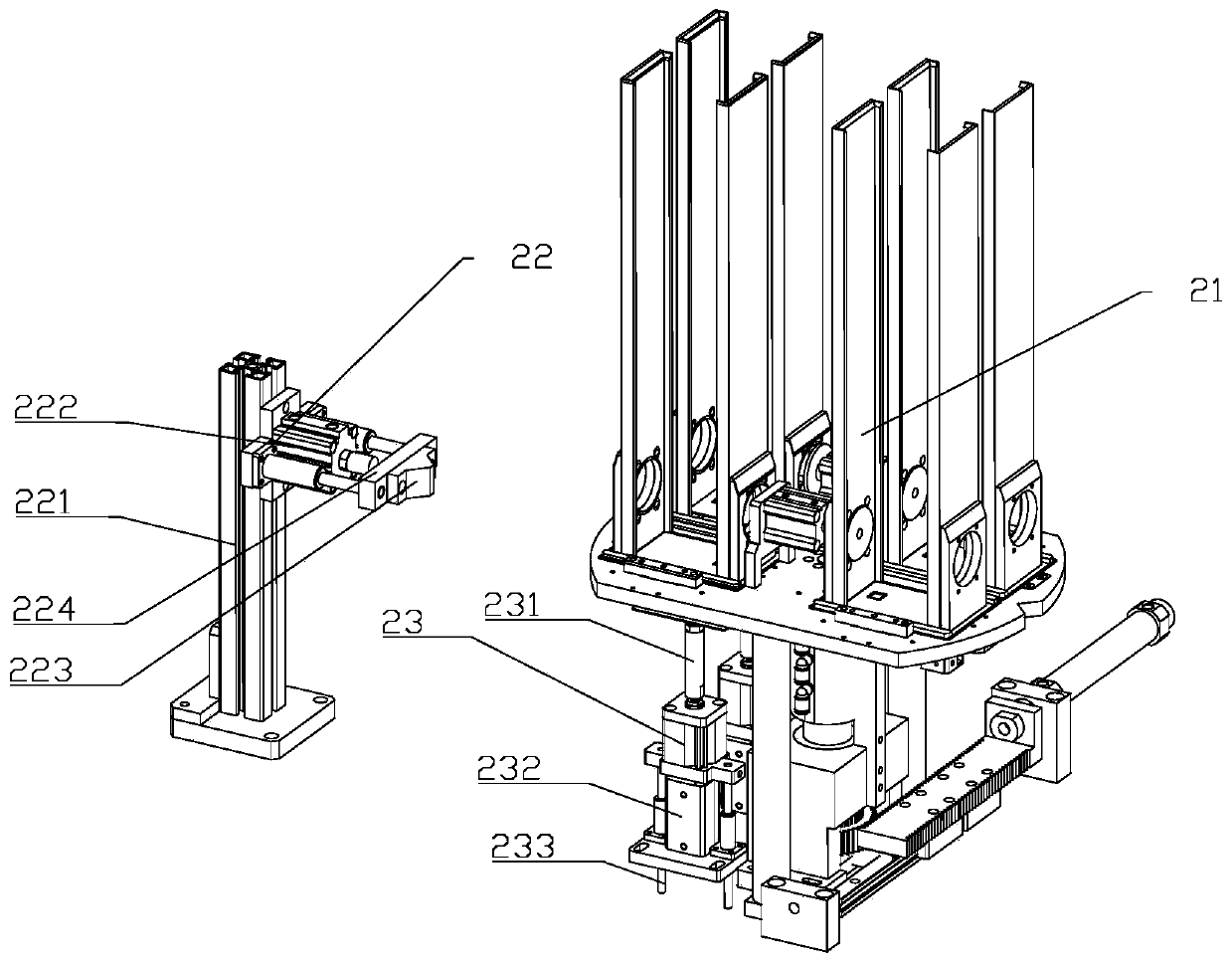

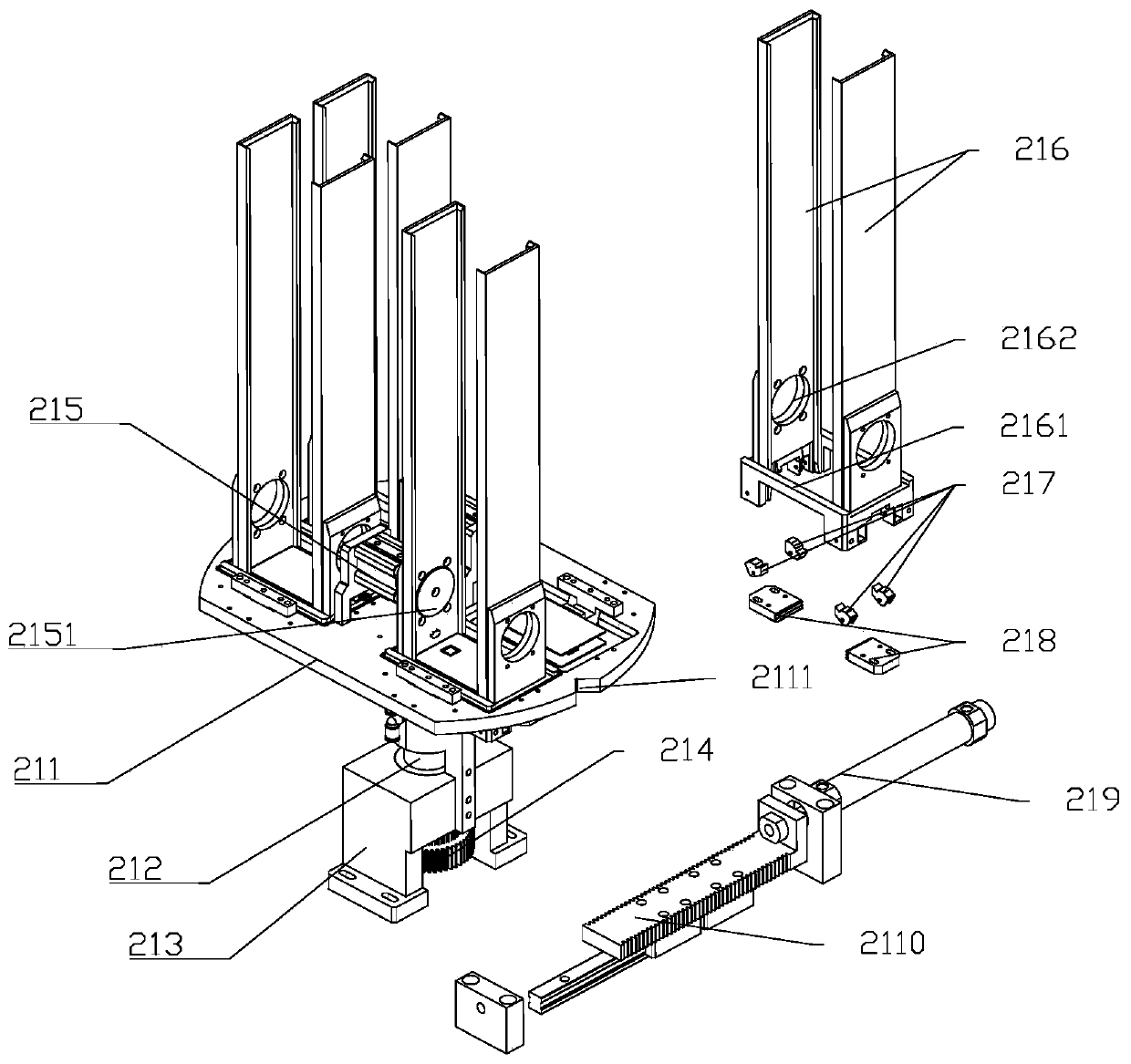

[0022] Such as figure 1 As shown, a kind of IC card groove milling machine comprises frame 1 and the IC card feeding device 2 that is installed on the frame 1, IC card delivery device 3, IC card positioning device 4, vertical groove milling device 5, blowing air Device 6 and collection box 7; IC card feeding device 2 is positioned at the feeding end of IC card conveying device 3, and described IC card positioning device 4 corresponds to IC card conveying device 3, and described vertical groove milling device 5 is installed on On the frame, the vertical groove milling device 5 is positioned directly above the IC card positioning device 4;

[0023] Described IC card feeding device 2 is used for storing IC card, and single IC card is placed in IC card conveying device 3; Described IC card conveying device 3 is used for conveying IC card step-by-step motion, in corresponding The station carries out corresponding processing; Described IC card positioning device 4 is used for clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com