Four-axle parallel five-head laser polishing machine

A technology of laser polishing and parallel connection, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., to achieve the effect of convenient operation, avoiding safety accidents and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

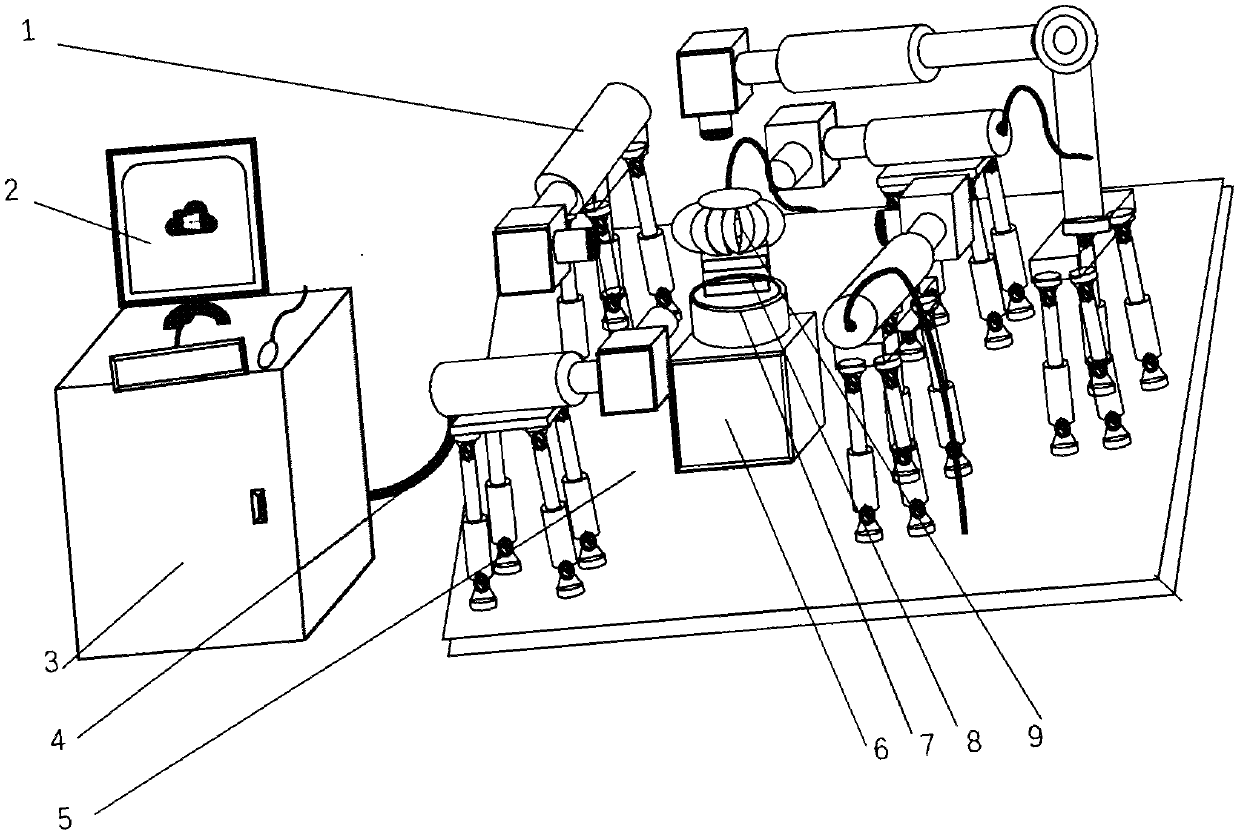

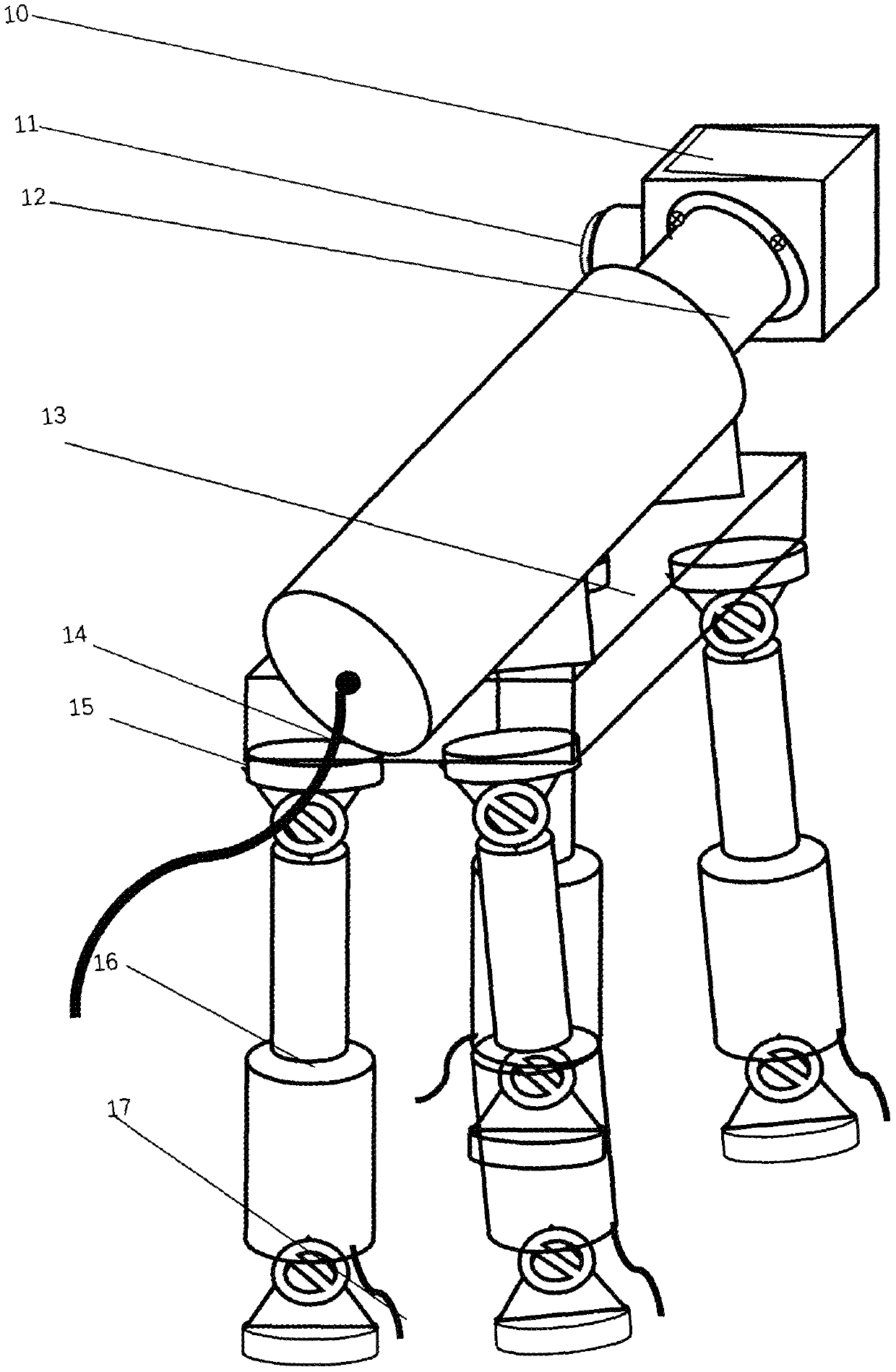

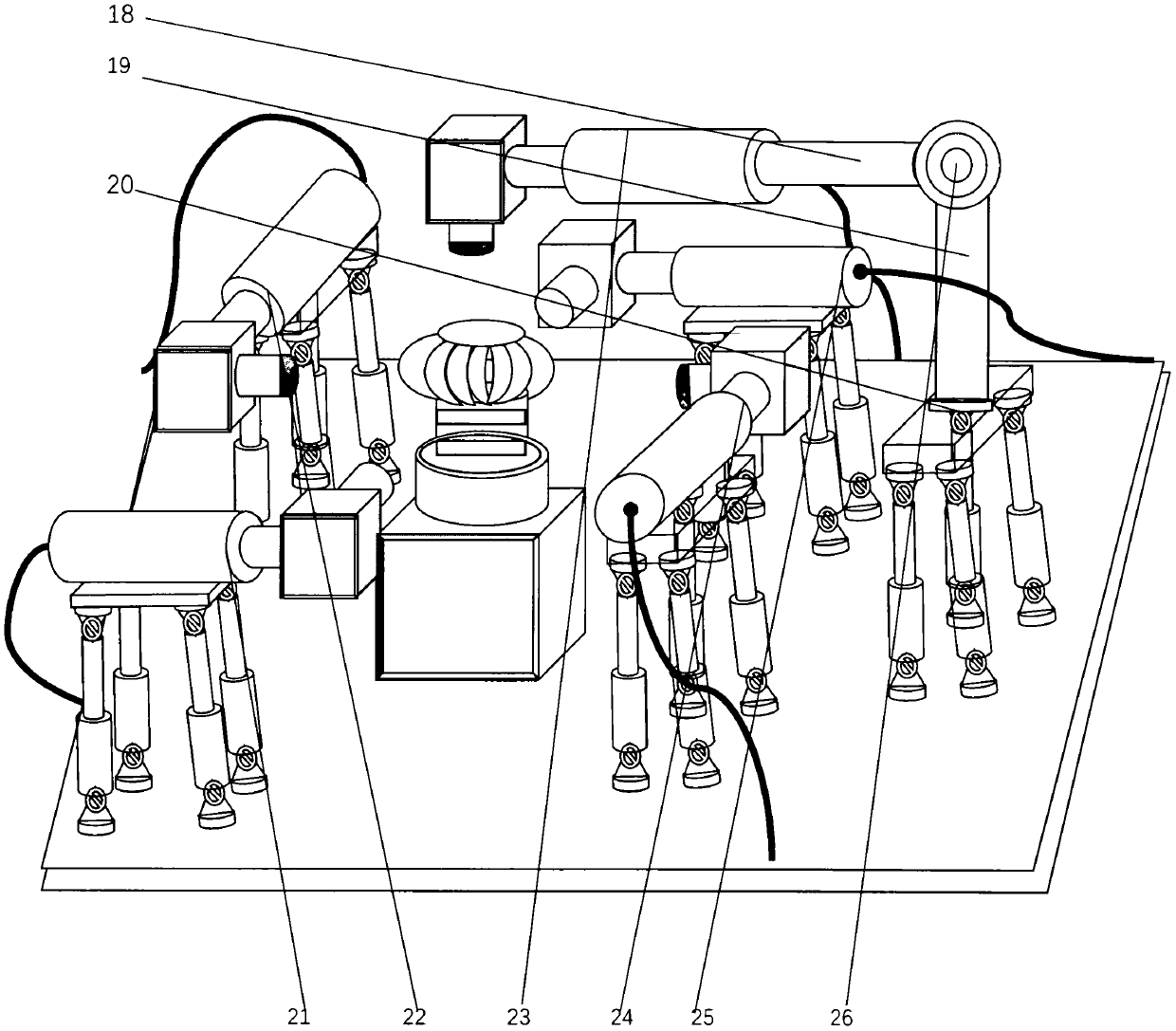

[0022] The specific embodiment of the present invention is as follows: four horizontal four-axis parallel laser scanning heads of east, south, west and north are arranged, and a vertical four-axis parallel laser scanning head 24 is arranged above the polishing piece. The four-axis parallel laser scanning head is composed as follows, the laser The scanner 10 is connected to the laser body 1 through the connector 12, the laser body is fixed on the four-axis parallel linkage plate 13 through the triangular support plate, and four numerical control telescopic rods 16 are arranged under the four-axis parallel linkage plate 13, and the four numerical control telescopic The base plate 5 is arranged below the rod 16, and the parallel linkage plate 13 forms a four-axis parallel structure with the four digital expansion rods 16 and the base plate 5. At one corner, the lower end of the numerical control telescopic rod 16 is connected and fixed on the base plate 5 through the universal hin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com