Oxidation ditch and MBBR integrated sewage treatment equipment

A technology of sewage treatment equipment and oxidation ditch, which is applied in the field of sewage treatment and rural sewage treatment, can solve the problems of high total nitrogen content in effluent quality, difficult transportation and installation and construction, and high labor and material costs, and achieves strong impact load resistance, The effect of convenient later operation and maintenance management and quick construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

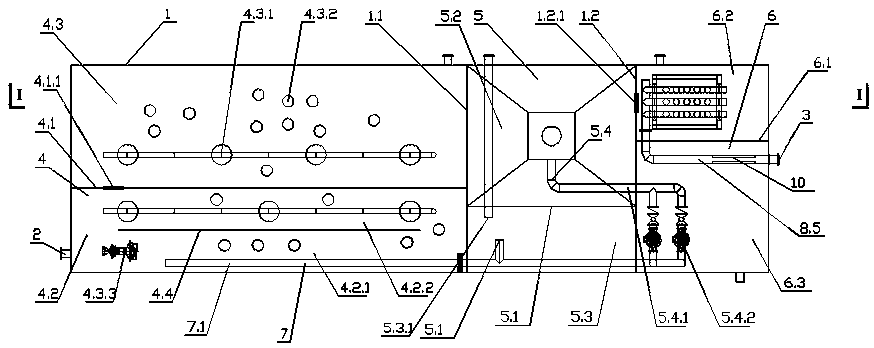

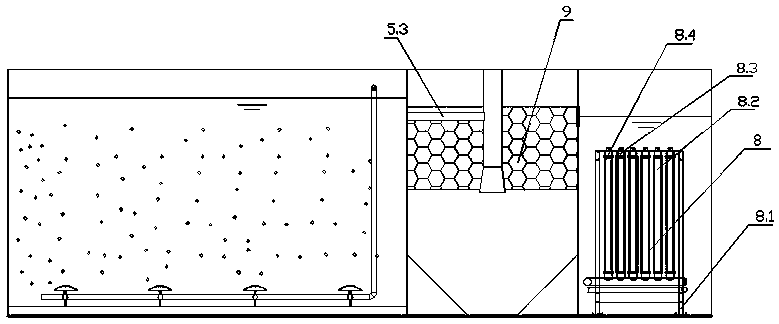

[0023] Embodiment 1: as figure 1 As shown, an integrated sewage treatment equipment of oxidation ditch + MBBR includes a horizontal shell 1, a water inlet 2 and a water outlet 3 respectively opened on the horizontal shell 1, and two water outlets set on the horizontal shell 1 A main partition, the first main partition 1.1 and the second main partition 1.2, the second main partition 1.2 is provided with a water outlet 1.2.1, the horizontal shell 1 is divided into three compartments, the first compartment 4 on the left It is the A / O area, the second compartment 5 in the middle is the sedimentation area, the third compartment 6 on the right is the water outlet area, the first compartment 4 is provided with a first dividing plate 4.1, and the first dividing plate 4.1 is provided with a water outlet 4.1.1 , the first partition plate 4.1 divides the A / O zone into the anoxic pool 4.2 and the aerobic pool 4.3 along the length direction of the horizontal shell 1, and the aerobic pool 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com