Preparation method of TiAl-based composite material with high product of strength and elongation

A technology of composite materials and high-strength plastic products, which is applied in the field of processing and preparation of titanium-aluminum intermetallic compound-based composite materials, can solve problems such as complex process routes and single reinforcement principles, and achieve the goal of improving plastic deformation capacity, increasing energy, and avoiding interface defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

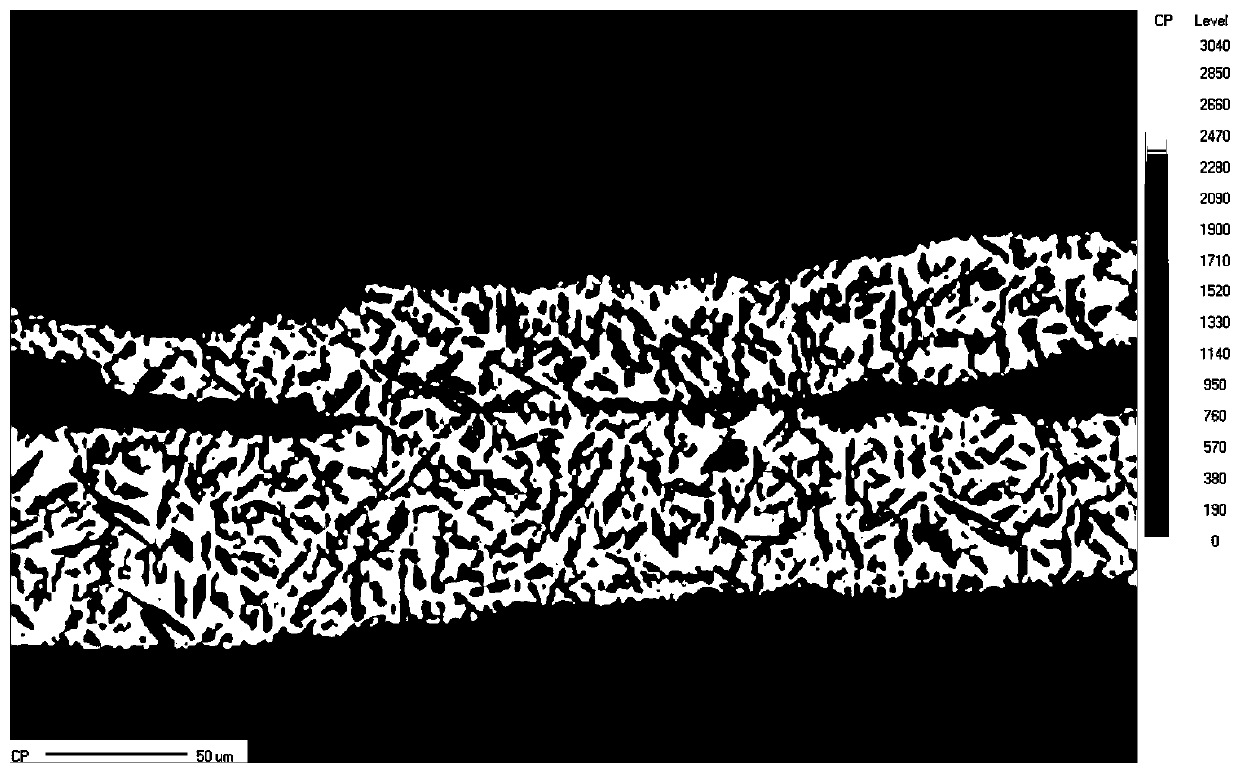

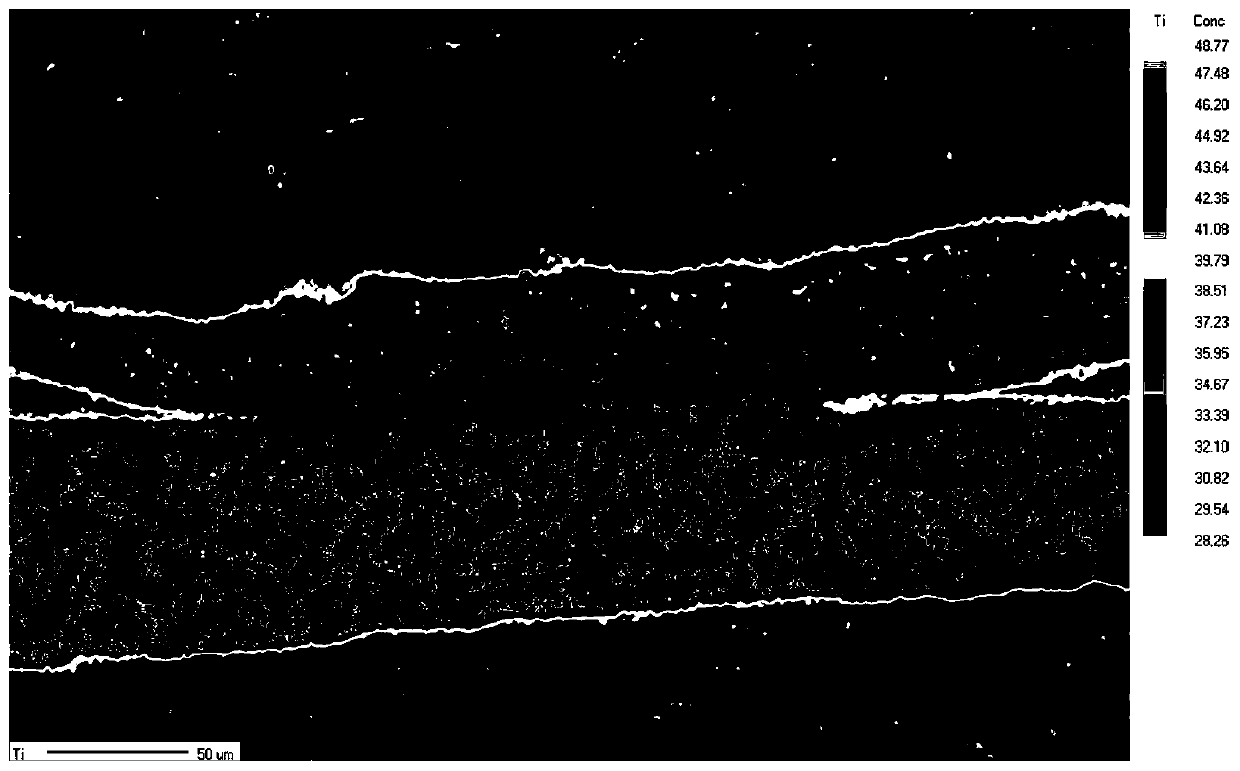

[0046] The Ti-45Al-5Nb-0.3W (at%) pre-alloyed powder prepared by the rotating electrode method with an atomic composition ratio of 98% and the Nb element powder with an atomic composition ratio of 2% were fully mixed in a V-type mixer 6 hours. Among them, the TiAl pre-alloyed powder is -100 mesh powder, the oxygen content is 780 ppm, and the Nb element powder is -200 mesh to -100 mesh, and the oxygen content is 450 ppm. Then put the fully mixed Nb element powder and TiAl alloy powder into a Φ100mm×200mm stainless steel sheath, vibrate, seal and then vacuumize at 520°C for 2.5 hours. The vacuum-pumped airtight tank was subjected to hot isostatic pressing for 5 hours at a temperature of 1260° C. and a pressure of 152 MPa, and then cooled in the furnace. Then a cylindrical billet with a size of Φ65mm×70mm was cut from the hot isostatic pressed billet, and packaged into a stainless steel sheath with a size of Φ85mm×110mm. Evenly coat the surface of the billet with anti-oxidation...

Embodiment 2

[0048] The Ti-45Al-5Nb-0.3W (at%) pre-alloyed powder prepared by the rotating electrode method with an atomic composition ratio of 95% and the Nb element powder with an atomic composition ratio of 5% were fully mixed in a V-type mixer 8 hours. Among them, the TiAl pre-alloyed powder is -100 mesh powder, the oxygen content is 780 ppm, and the Nb element powder is -200 mesh to -100 mesh, and the oxygen content is 450 ppm. Then put the fully mixed Nb element powder and TiAl alloy powder into a Φ100mm×200mm stainless steel sheath, vibrate, seal and then vacuumize at 550°C for 3 hours. The sealed tank that has been vacuumed is subjected to hot isostatic pressing at a temperature of 1255° C. and a pressure of 155 MPa for 5.5 hours, and then cooled in the furnace. Then a cylindrical billet with a size of Φ65mm×70mm was cut from the hot isostatic pressed billet, and packaged into a stainless steel sheath with a size of Φ85mm×110mm. Evenly coat the surface of the billet with anti-oxi...

Embodiment 3

[0050] The Ti-45Al-5Nb-0.3W (at%) pre-alloyed powder prepared by the rotating electrode method with an atomic composition ratio of 99% and the Nb element powder with an atomic composition ratio of 1% are fully mixed in a V-shaped mixer 5 hours. Among them, the TiAl pre-alloyed powder is -100 mesh powder, the oxygen content is 780 ppm, and the Nb element powder is -200 mesh to -100 mesh, and the oxygen content is 450 ppm. Then put the fully mixed Nb element powder and TiAl alloy powder into a Φ100mm×200mm stainless steel sheath, vibrate, seal and then vacuumize at 550°C for 2 hours. The vacuum-pumped sealed tank was subjected to hot isostatic pressing for 5.5 hours at a temperature of 1265° C. and a pressure of 150 MPa, and then cooled in the furnace. Then a cylindrical billet with a size of Φ65mm×70mm was cut from the hot isostatic pressed billet, and packaged into a stainless steel sheath with a size of Φ85mm×110mm. Evenly coat the surface of the billet with anti-oxidation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com