A kind of preparation method of high-strength plastic matrix composite material

A composite material and high-strength plastic product technology, which is applied in the field of processing and preparation of titanium-aluminum intermetallic compound-based composite materials, can solve the problems of complex process route and single reinforcement principle, and achieve the effect of simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

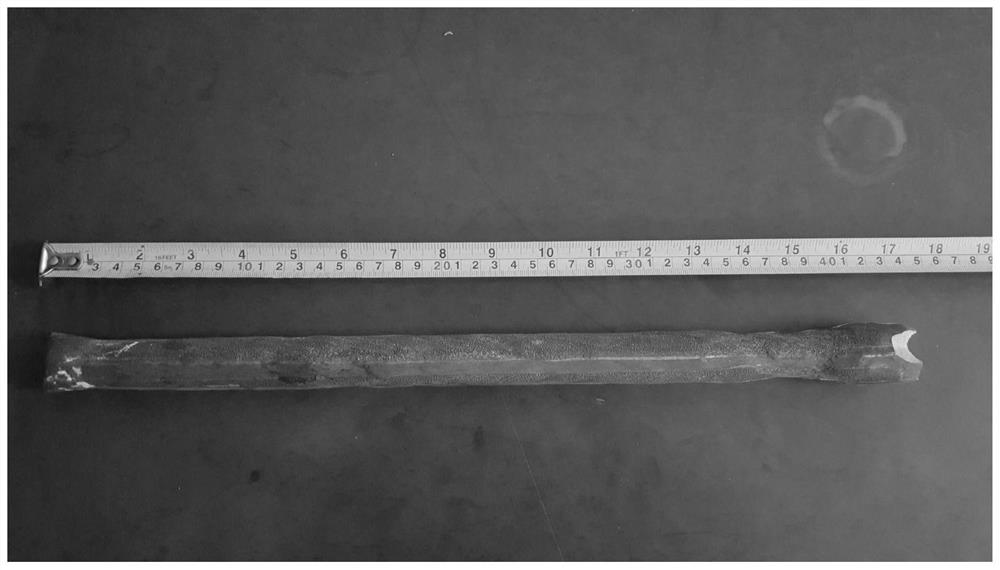

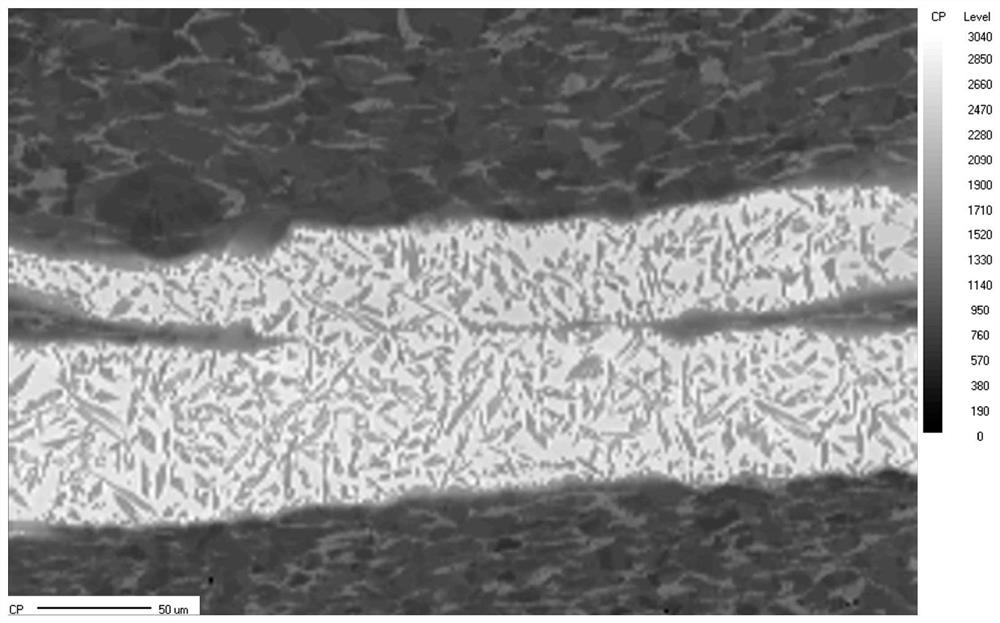

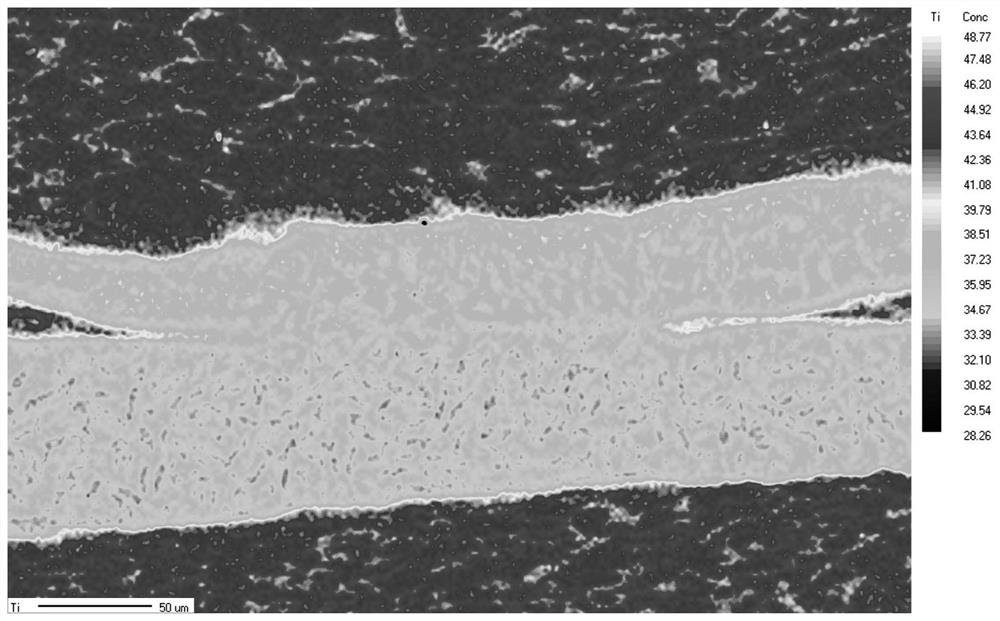

[0046] The Ti-45Al-5Nb-0.3W (at%) pre-alloyed powder prepared by the rotating electrode method with an atomic composition ratio of 98% and the Nb element powder with an atomic composition ratio of 2% were fully mixed in a V-type mixer 6 hours. Among them, the TiAl pre-alloyed powder is -100 mesh flour, the oxygen content is 780ppm, and the Nb element powder is -200 mesh to -100 mesh, and the oxygen content is 450ppm. Then put the fully mixed Nb element powder and TiAl alloy powder into a Φ100mm×200mm stainless steel sheath, vibrate, seal and then vacuumize at 520°C for 2.5 hours. The sealed tank that has been evacuated is at a temperature of 1260 ° C and a pressure of 152 MPa, and is cooled with the furnace after hot isostatic pressing for 5 hours. Then a cylindrical billet with a size of Φ65mm×70mm was cut from the hot isostatic pressed billet, and packaged into a stainless steel sheath with a size of Φ85mm×110mm. Evenly coat the surface of the billet with anti-oxidation gl...

Embodiment 2

[0048] The Ti-45Al-5Nb-0.3W (at%) pre-alloyed powder prepared by the rotating electrode method with an atomic composition ratio of 95% and the Nb element powder with an atomic composition ratio of 5% were fully mixed in a V-type mixer 8 hours. Among them, the TiAl pre-alloyed powder is -100 mesh powder, the oxygen content is 780 ppm, and the Nb element powder is -200 mesh to -100 mesh, and the oxygen content is 450 ppm. Then put the fully mixed Nb element powder and TiAl alloy powder into a Φ100mm×200mm stainless steel sheath, vibrate, seal and then vacuumize at 550°C for 3 hours. The vacuum-pumped airtight tank was subjected to hot isostatic pressing for 5.5 hours at a temperature of 1255° C. and a pressure of 155 MPa, and then cooled in the furnace. Then a cylindrical billet with a size of Φ65mm×70mm was cut from the hot isostatic pressed billet, and packaged into a stainless steel sheath with a size of Φ85mm×110mm. Evenly coat the surface of the billet with anti-oxidation...

Embodiment 3

[0050] The Ti-45Al-5Nb-0.3W (at%) pre-alloyed powder prepared by the rotating electrode method with an atomic composition ratio of 99% and the Nb element powder with an atomic composition ratio of 1% are fully mixed in a V-shaped mixer 5 hours. Among them, the TiAl pre-alloyed powder is -100 mesh flour, the oxygen content is 780ppm, and the Nb element powder is -200 mesh to -100 mesh, and the oxygen content is 450ppm. Then put the fully mixed Nb element powder and TiAl alloy powder into a Φ100mm×200mm stainless steel sheath, vibrate, seal and then vacuumize at 550°C for 2 hours. The vacuum-pumped airtight tank was subjected to hot isostatic pressing for 5.5 hours at a temperature of 1265° C. and a pressure of 150 MPa, and then cooled in the furnace. Then a cylindrical billet with a size of Φ65mm×70mm was cut from the hot isostatic pressed billet, and packaged into a stainless steel sheath with a size of Φ85mm×110mm. Evenly coat the surface of the billet with anti-oxidation g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com