Excavator track steel BG45MnCrB and preparation method thereof

An excavator and crawler technology, which is applied in the field of excavator crawler steel BG45MnCrB and its preparation, can solve problems such as easy oxidation and burning, and achieve the effects of ensuring uniformity, reducing alloy costs, and reducing burning factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

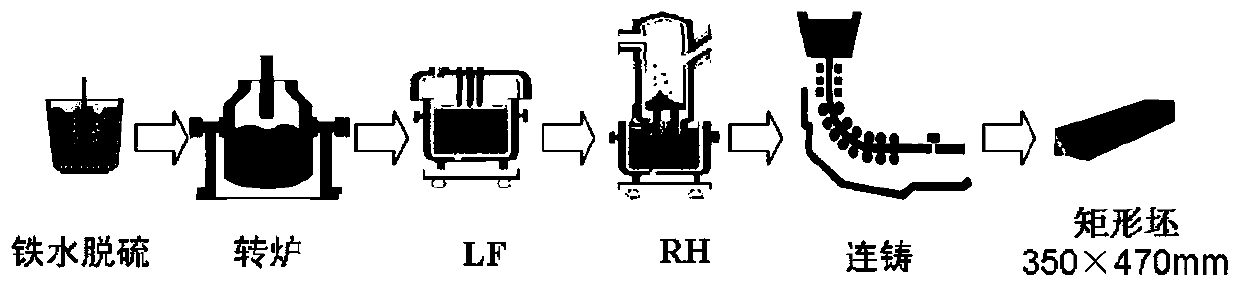

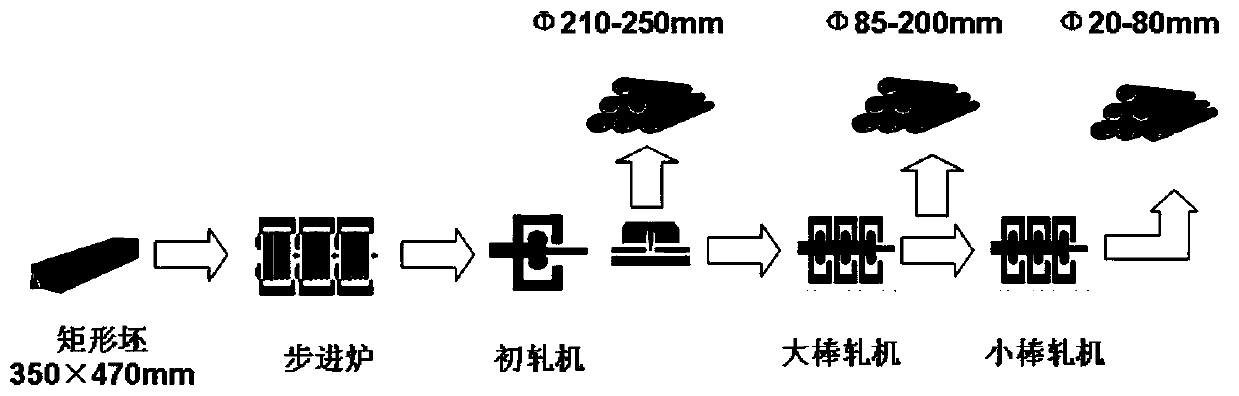

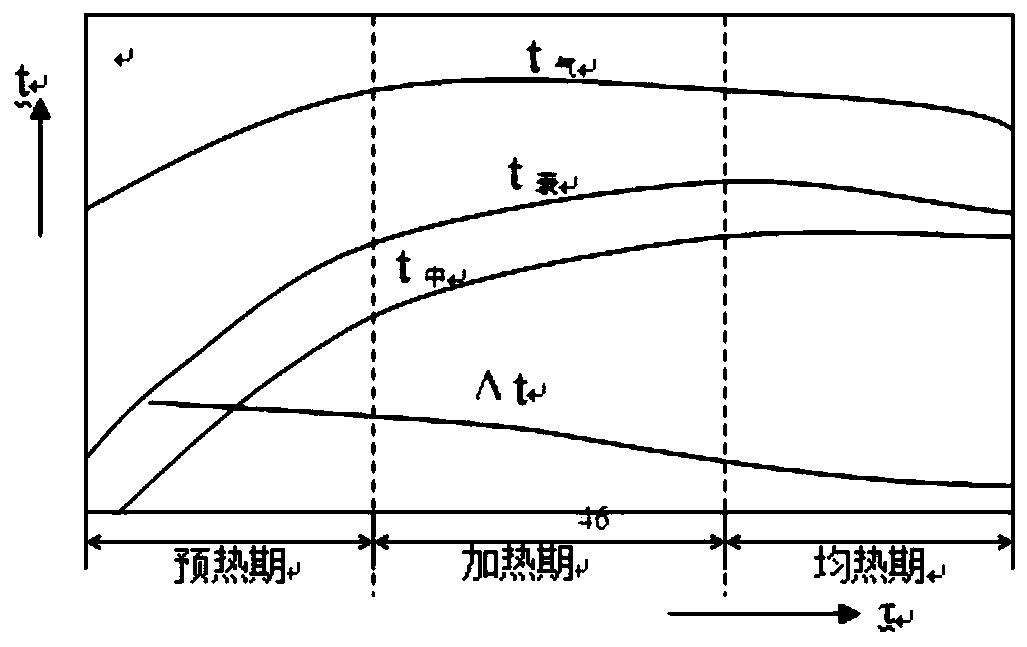

Method used

Image

Examples

Embodiment 1

[0024] Chemical Composition Design

[0025] The hardenability of steel refers to the ability of the steel to obtain the depth of the hardened layer (martensite layer) when quenched under certain conditions, which is mainly related to the stability of the supercooled austenite of the steel and the critical cooling rate of the steel.

[0026] Common elements that improve hardenability include C, Mn, Cr, Ni, Mo, B, and W; among them, the element C has the greatest influence, and it has a critical point, when the carbon content is greater than 1.2%. , the cooling rate of the steel increases, the C curve shifts to the left, and the hardenability decreases. When the carbon content is less than 1.2%, as the carbon concentration in the steel increases, the cooling rate also decreases significantly, then the C curve shifts to the right, and the hardenability of the steel increases.

[0027] a. In order to ensure the toughness and surface hardness of the track steel core, the end harde...

Embodiment 2

[0049] The excavator track steel BG45MnCrB prepared in the manner of Example 1 is characterized as follows:

[0050] (1) Low-magnification tissue

[0051] General loose loose center Ingot shape segregation center segregation 0.5 0.5 0.5 0 0.5 0.5 0.5 0

[0052] (2) Non-metallic inclusions

[0053] A rough A fine B thick B thin C thick C thin D thick 1.0 1.0 0.5 0.5 0 0 0

[0054] (3) Grain size

[0055] The grain size grades are all grade 7, and there is no mixed crystal phenomenon.

[0056] (4) Decarburization layer

[0057] Decarburization layer depth is 0.3mm.

[0058] (5) End hardenability

[0059] (6) The chemical composition adopts narrow composition control to ensure that the qualified rate of hardenability at the end of the steel reaches 100%, the fatigue life is long, the wear resistance is good, and it is easy for customers to process and use.

[0060] (7) Physical chemical composition %: C:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com