Superstructure mute chamber

A silent room and wall technology, applied in sound insulation, building components, special buildings, etc., can solve the problems of easy aging and deterioration, peculiar smell, ventilation for a period of time, etc., to achieve good sound absorption effect, reduce toxicity, The effect of shortening the lead time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

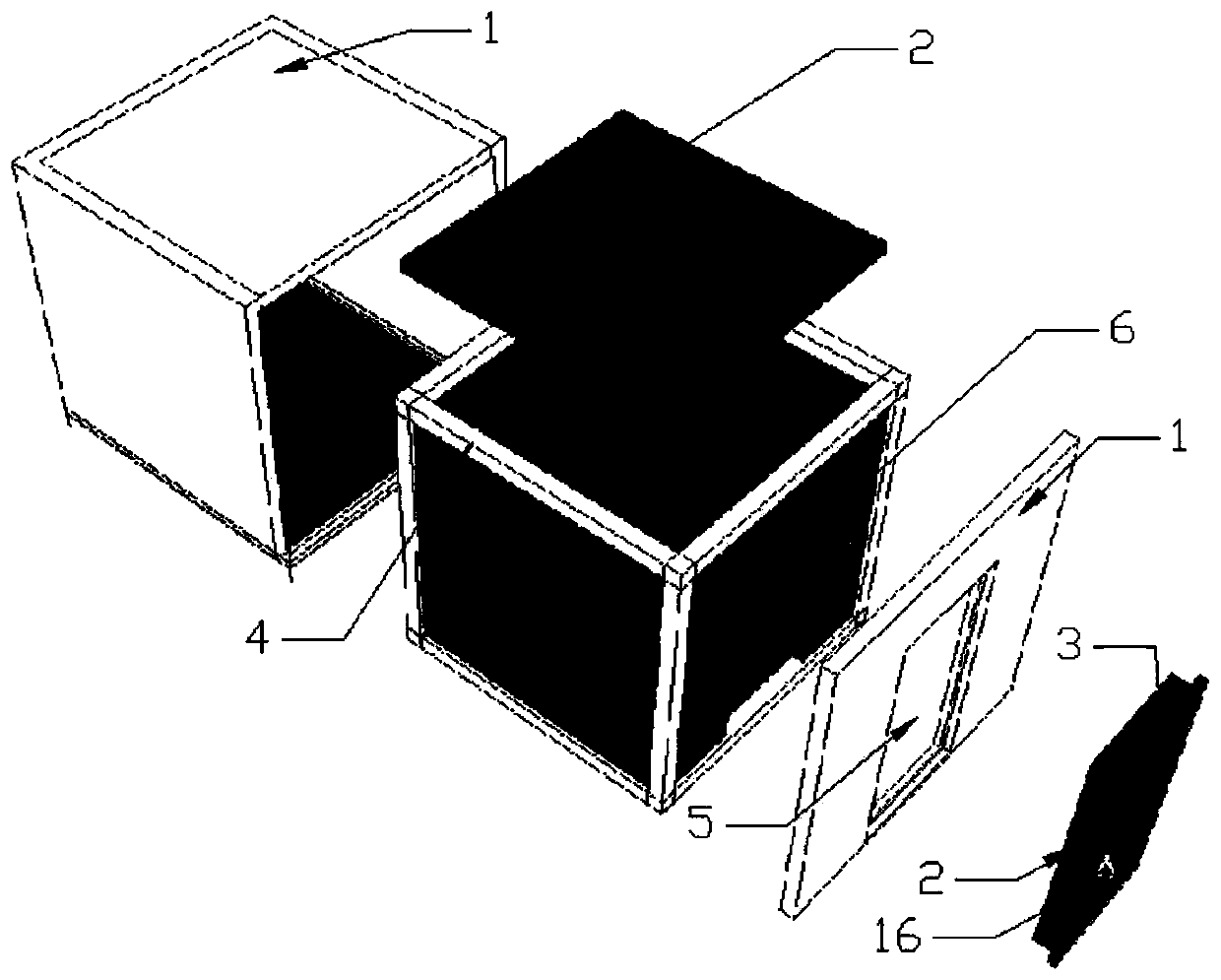

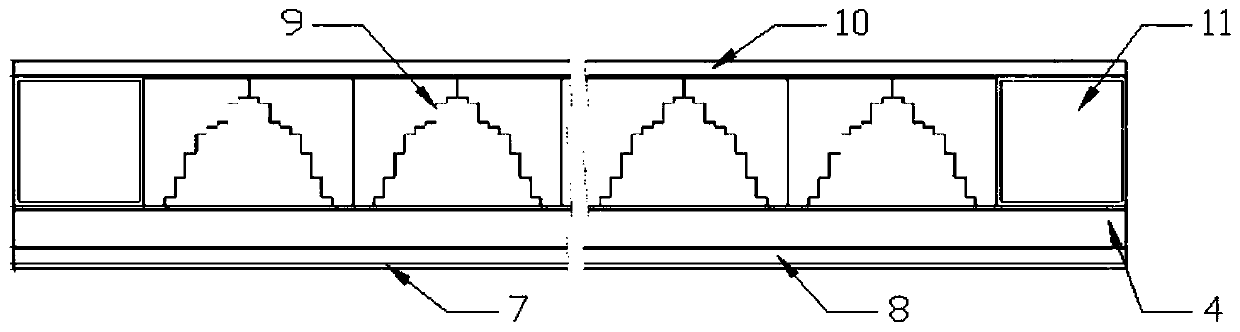

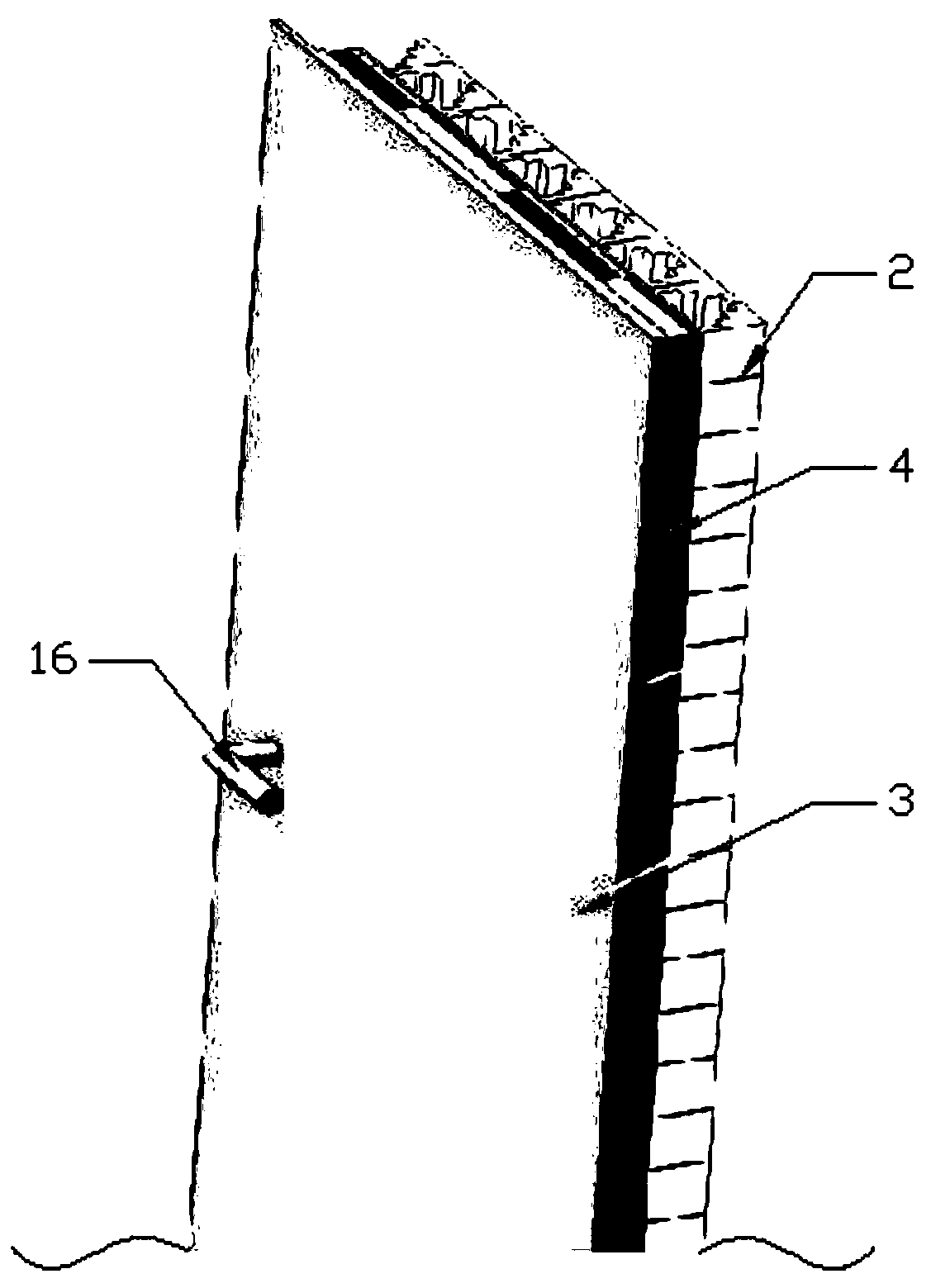

[0023] Such as Figure 1 to Figure 4 As shown, a superstructure silent room includes an outer wall 1, an inner wall 2 and a door panel 3, the outer wall 1 and the inner wall 2 are hollow cuboids, and the inner wall of the outer wall 1 passes through the fixing frame 4 Connect the outer wall of the inner wall 2, one end side wall of the outer wall 1 and the inner wall 2 are respectively provided with a first through hole 5 and a second through hole 6, and one end of the first through hole 5 and the second through hole 6 The side walls are all hinged with one end side wall of the door panel 3, the outer wall 1 includes an outer decorative layer 7, the inner wall of the outer decorative layer 7 is provided with a sound insulation layer 8, and the inner wall 2 includes a sound-absorbing superstructure material layer 9, absorbing The acoustic superstructure material layer 9 includes several unit bodies, the unit body is composed of a wavelength tube and a Helmholtz resonance cavity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com