Straw bale drying equipment

A technology for drying equipment and straw bales, which is applied in the direction of drying solid materials, drying gas arrangement, non-progressive dryers, etc., can solve the problems of low moisture content of forage grass, easy shedding of flowers and leaves of forage grass, etc., and achieves high work efficiency, The overall structure is reasonable and the operation is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

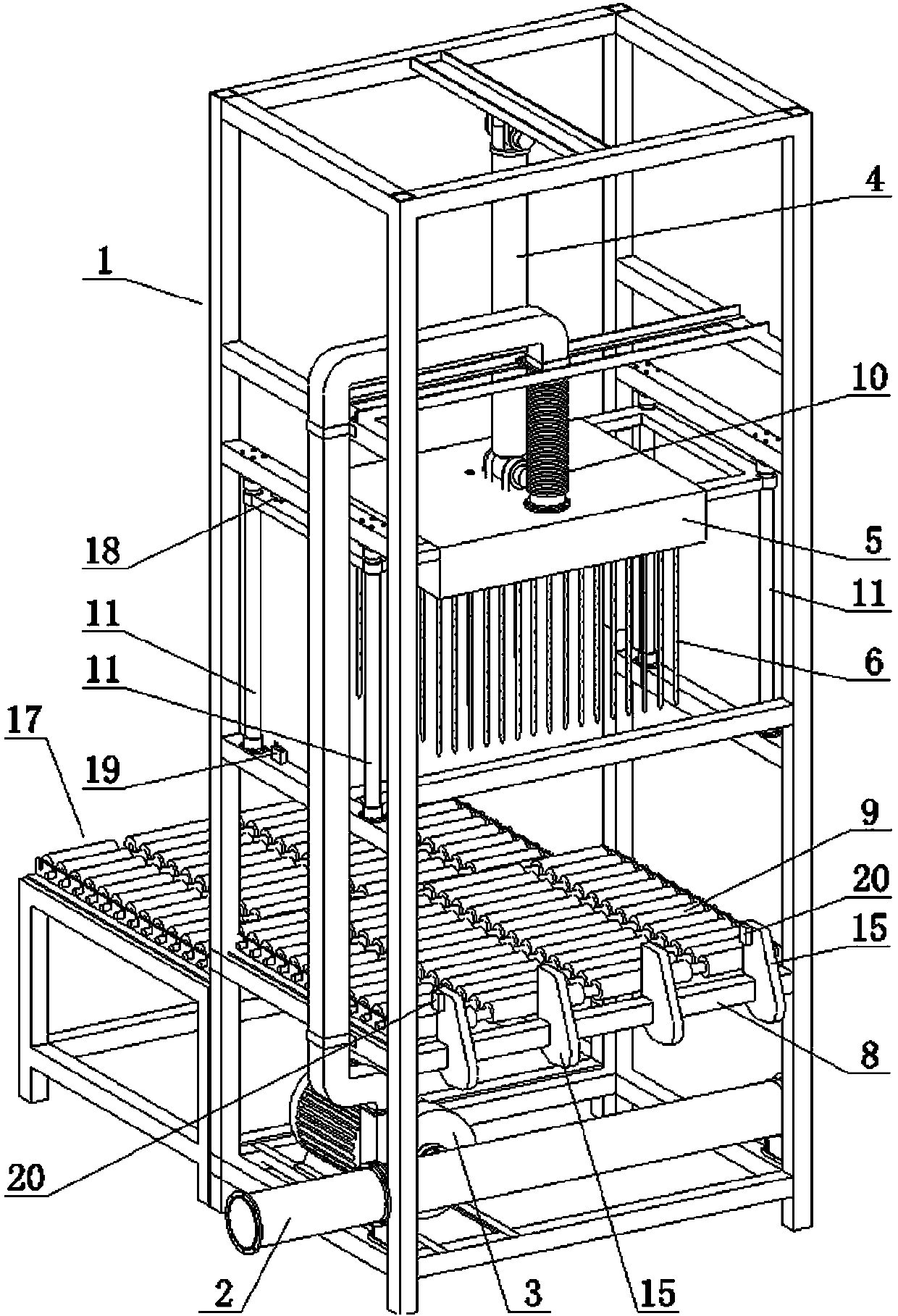

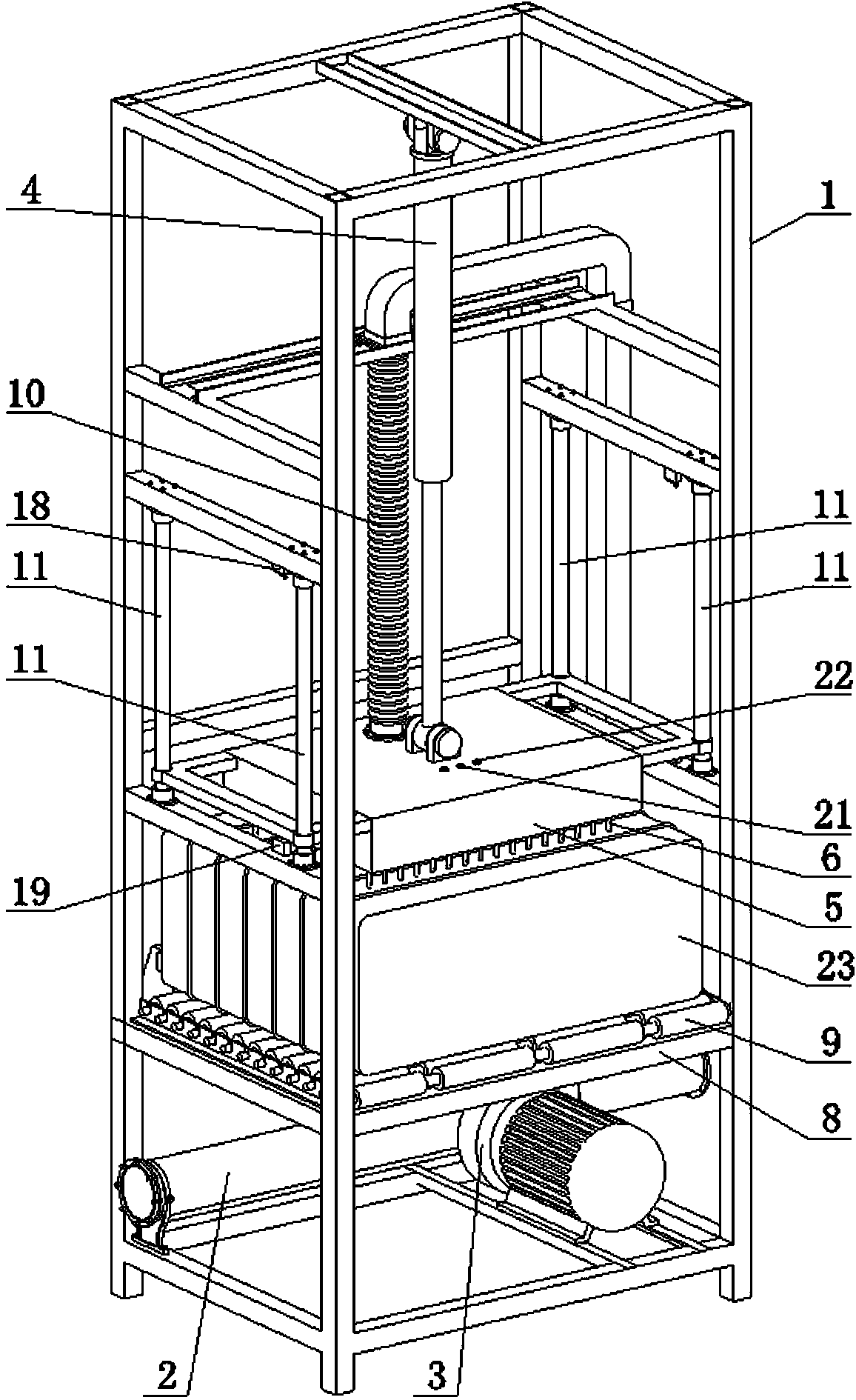

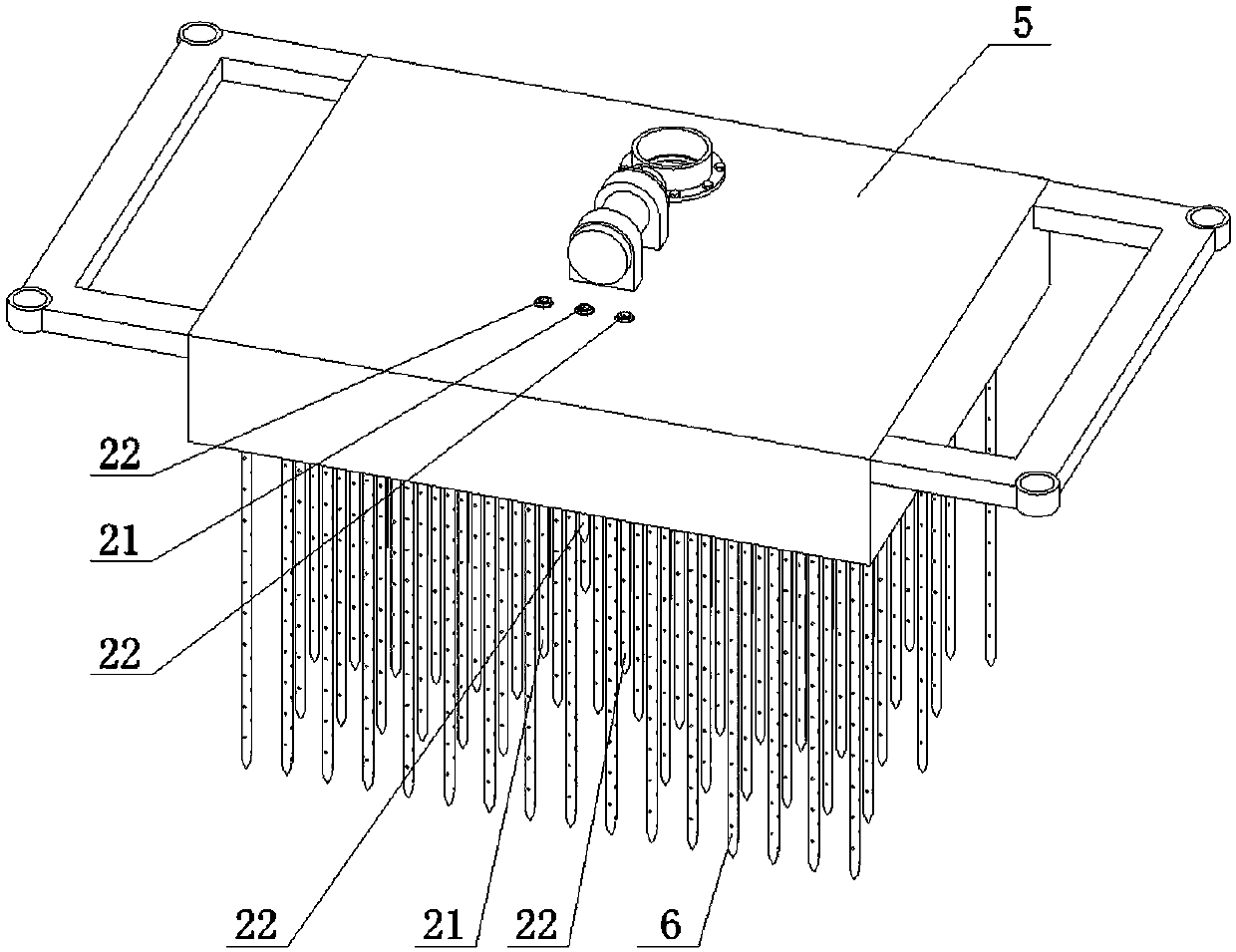

[0031] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 10 and Figure 11 Shown, a kind of bale drying equipment, it comprises frame 1, fan 3, the heat source pipeline 2 that provides hot blast to fan 3, hydraulic system, oil cylinder 4 and wind collecting box 5; And on the bale platform formed by some supporting rollers 9 arranged horizontally on the four frame 8, four grass claws 15 are arranged on the front side frame of the four frame 8; the fan 3 is arranged at the bottom of the frame 1, The air outlet of the fan 3 is connected to the top of the wind collecting box 5 through the high temperature resistant telescopic air duct 10; The hollow air supply needle 6 capable of inserting and pulling out the bale 23, the hollow air supply needle 6 is provided with several air outlet holes 7; The bottom end of the cylinder tube is connected to the upper end of the frame 1, and the top end of the piston rod of the oil cylinder 4 is connected to the upper side of the w...

Embodiment 2

[0034] Embodiment 2: as Figure 4 , Figure 5 , Figure 6 , Figure 10 and Figure 12 Shown, a kind of bale drying equipment, it comprises frame 1, fan 3, the heat source pipeline 2 that provides hot blast to fan 3, hydraulic system, two oil cylinders 4 and wind collecting box 5; The frame 8 and the bale platform formed by some supporting rollers 9 arranged laterally on the four frame 8 are provided with four weed retaining claws 15 on the front side frame of the four frame 8; At the bottom, the air outlet of the fan 3 is connected to the side of the wind collecting box 5 through the high temperature resistant telescopic air duct 10; Install some hollow air supply needles 6 capable of inserting and pulling out the bales 23, and the hollow air supply needles 6 are provided with some air outlet holes 7; The bottom of cylinder 4 is connected to the lower part of frame 1, the top of piston rod of cylinder 4 is connected to the two sides of air collecting box 5, and the rear s...

Embodiment 3

[0036] Embodiment 3: as Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 Shown, a kind of bale drying equipment, it comprises frame 1, fan 3, the heat source pipeline 2 that provides hot blast to fan 3, hydraulic system, two oil cylinders 4 and wind collecting box 5; The frame 8 and the bale platform formed by some supporting rollers 9 arranged laterally on the four frame 8 are provided with four weed retaining claws 15 on the front side frame of the four frame 8; At the bottom, the air outlet of the blower fan 3 is connected to the following of the wind collecting box 5 through a high-temperature-resistant telescopic air duct; Some hollow air supply needles 6 capable of inserting and extracting straw bales 23 are provided with some air outlet holes 7 on the hollow air supply needle 6; The sides are respectively provided with oil cylinders 4 that drive the air collecting box 5 to slide up and down, and the bottom ends of the two oil cylinders 4 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com