Device for detecting and sampling urea-formaldehyde resin in porcelain-imitating tableware

A technology of urea-formaldehyde resin and sampling equipment, which is applied in sampling devices, lighting and heating equipment, household appliances, etc. Detection accuracy and other issues, to avoid thermal hydrolysis, increase the contact area, and improve the detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

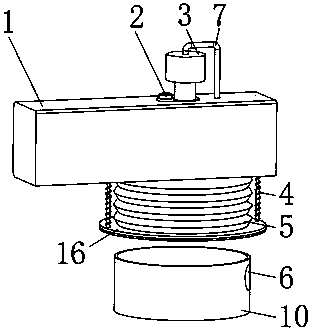

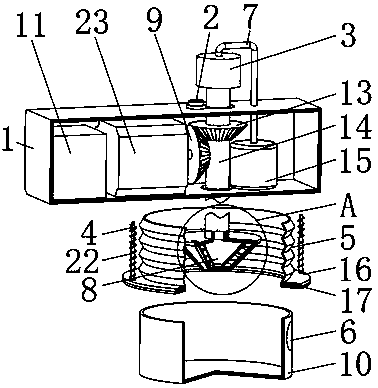

[0037] Example 1: Please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , This embodiment discloses a detection and sampling device for urea-formaldehyde resin in melamine tableware, including a driving part, a grinding part, an air injection part and a rotating tube 14 with perforations along the length direction.

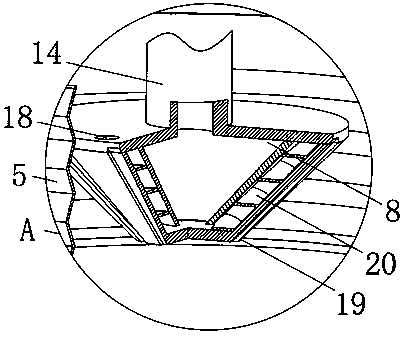

[0038] The grinding part of this embodiment includes an upper plate 21 and an outer conical grinding cover 19 with the small end facing downwards. The large end of the outer conical grinding cover 19 is open and the small end is sealed. The side of the plate 21 is fixed and sealed, and the upper plate 21 is provided with an air outlet 18 connected to the inner cavity of the outer conical grinding cover 19, and a number of grooves 12 are provided on the outer side of the outer conical grinding cover 19, and the grooves 12 are not perpendicular to the axis , the upper plate 21 is connected to the lower end of the rotating tube 14, and the per...

Embodiment 2

[0054] Embodiment two: if image 3 with Figure 4 As shown, this embodiment discloses a detection and sampling device for urea-formaldehyde resin in melamine tableware. Downward inner conical cover 8, the inner conical cover 8 is positioned in the outer conical grinding cover 19, the upper end of the inner conical cover 8 is fixedly connected with the lower side of the upper plate 21, the inner chamber of the inner conical cover 8 and the rotating The perforations of the tube 14 communicate.

[0055] Further, the helical blade 20 is located between the inner conical cover 8 and the outer conical grinding cover 19, the helical blade 20, the inner conical cover 8 and the outer conical grinding cover 19 form a spiral passage, the lower end of the helical passage and the inner cone The inner cavity of the shape cover 8 communicates, and the upper end of the spiral channel communicates with the outside world through the air outlet 18.

[0056] The working process and principle o...

Embodiment 3

[0058] Embodiment three: as figure 2 As shown, this embodiment discloses a detection and sampling device for urea-formaldehyde resin in melamine tableware. , the motor 23 and the power supply 11, the motor 23 is fixed on the housing 1, and the first gear 9 is installed on the output shaft of the motor 23, the second gear 13 adapted to the first gear 9 is installed on the rotating tube 14, the motor The input end of 23 and the input end of the air pump 15 are both electrically connected to the output end of the control switch group 2, and the input end of the control switch group 2 is electrically connected to the output end of the power supply 11.

[0059] Preferably, both the first gear 9 and the second gear 13 are bevel gears or both the first gear 9 and the second gear 13 are spur gears.

[0060] The control switch group 2 is provided with control buttons corresponding to the motor 23 and the air pump 15 respectively, and the control switch group 2 controls the working st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com