Flat wire continuously-wound linear coil and inductor

A flat wire and straight line technology, applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor parts, circuits, etc., can solve problems such as complicated steps, insufficiently compact flat wire winding, and chemical reagent pollution , to save cost, improve cooling effect and reduce the use of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

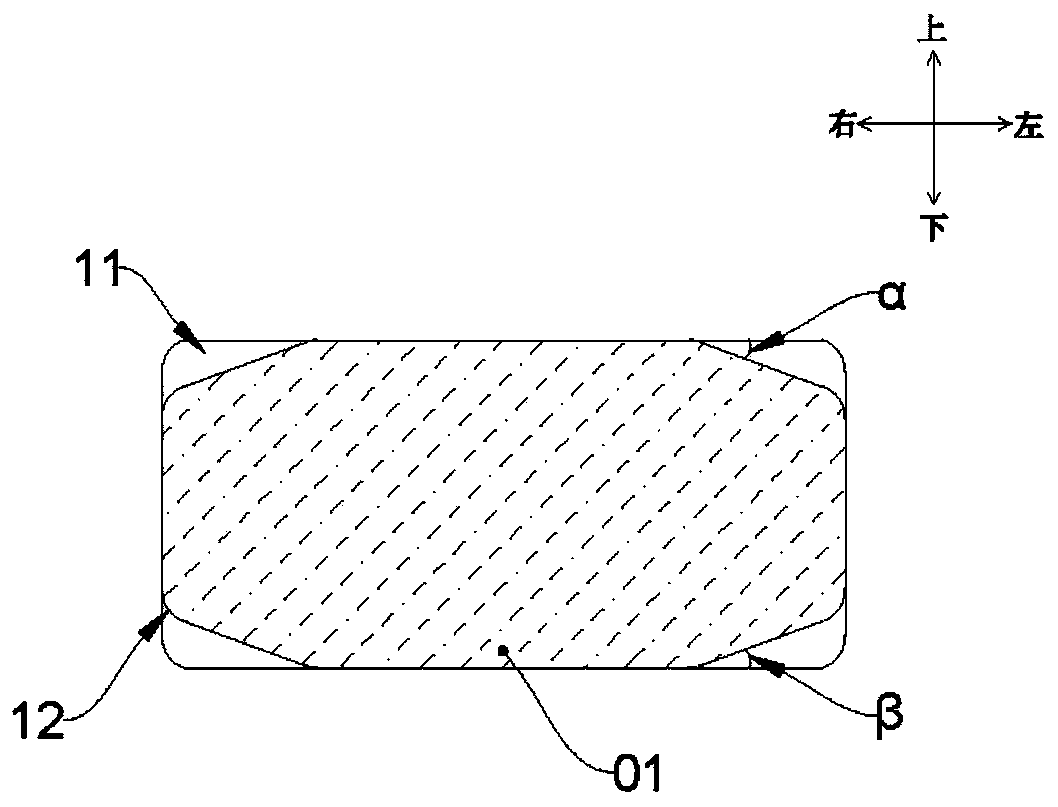

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods. It is worth noting that, image 3 and Figure 4 The directional coordinates shown in , and the directional words such as up, down, left, and right described in the present invention are only used to better explain the present invention, but are not used to limit the present invention.

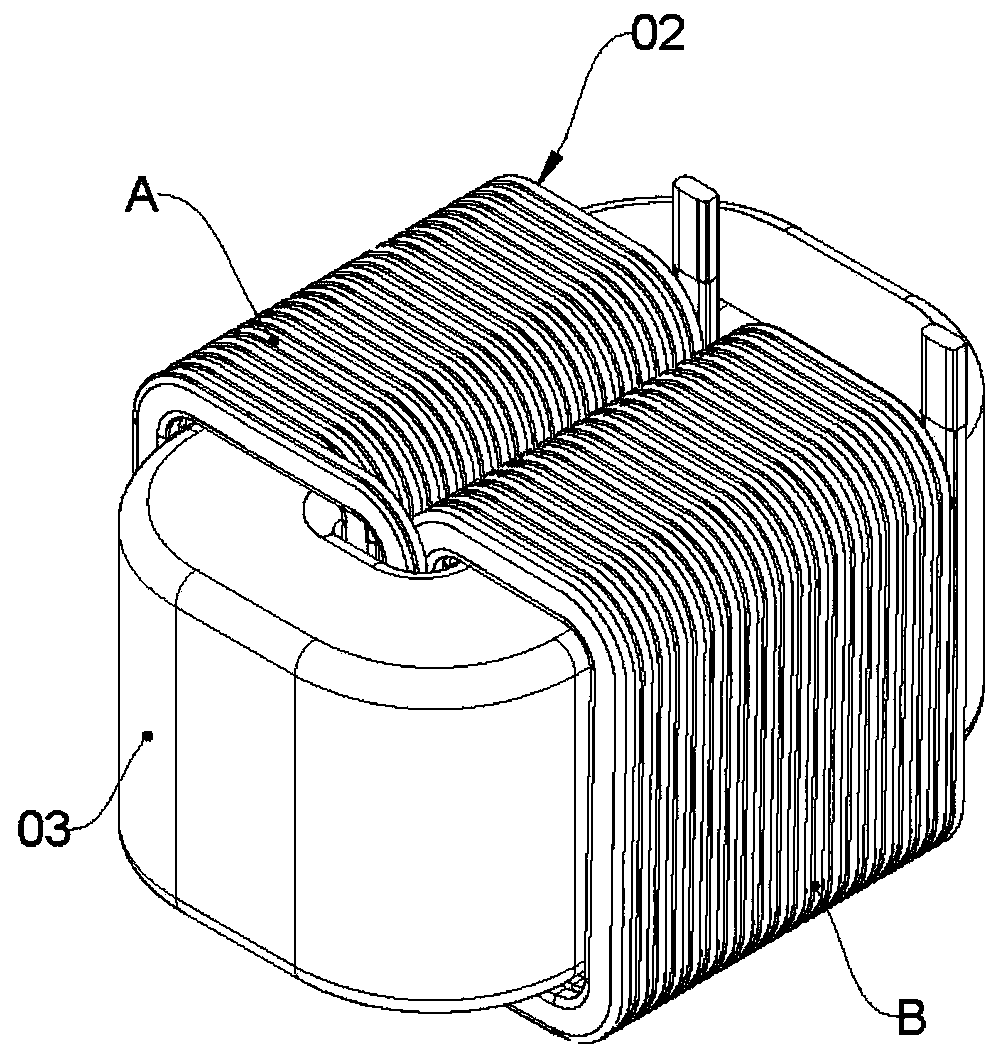

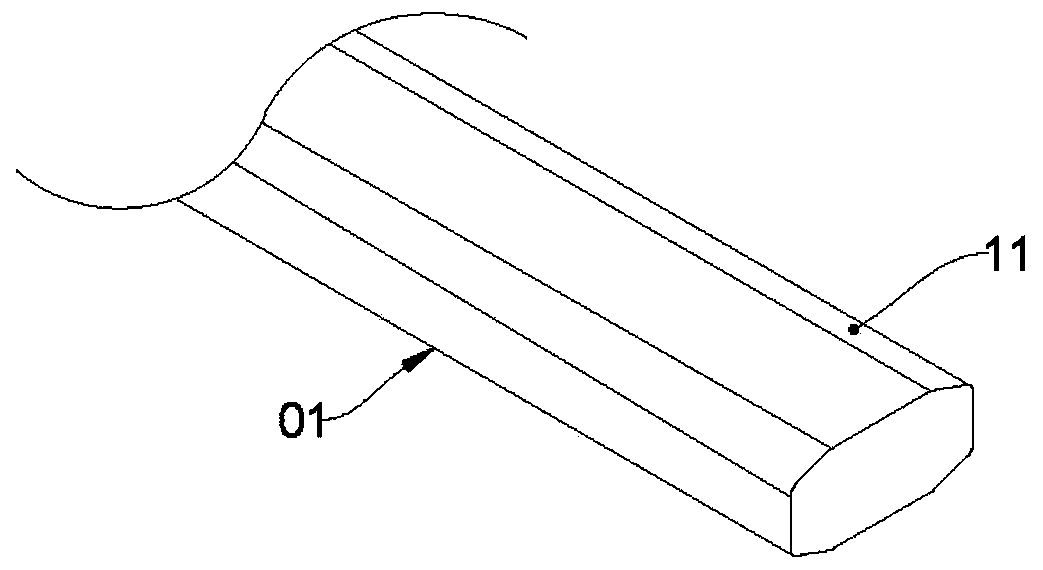

[0028] Please refer to Figure 1-3 , the present invention proposes a linear coil wound with a flat wire, wherein the linear coil 02 continuously wound with a flat wire includes a coil A and a coil B, the winding directions of the coil A and the coil B are opposite, and The coil A and the coil B are wound by the same flat wire 01; the flat wire 01 has a quadrangular prism structure, the cross section of the flat wire 01 is rectangular, and the four edges of the flat wire 01 are respectively provided with There are c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com