AGM storage battery inner formation process and AGM start-stop storage battery

A storage battery, internalization technology, applied in the direction of lead-acid battery, lead-acid battery construction, battery pack parts, etc. ability, improve the efficiency of formation, and reduce the effect of assembly pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

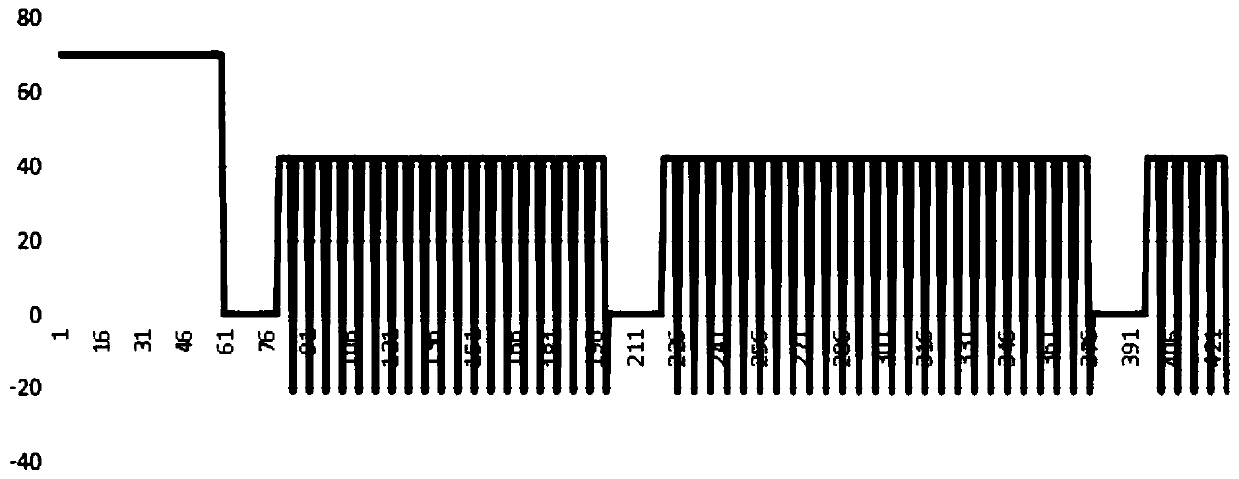

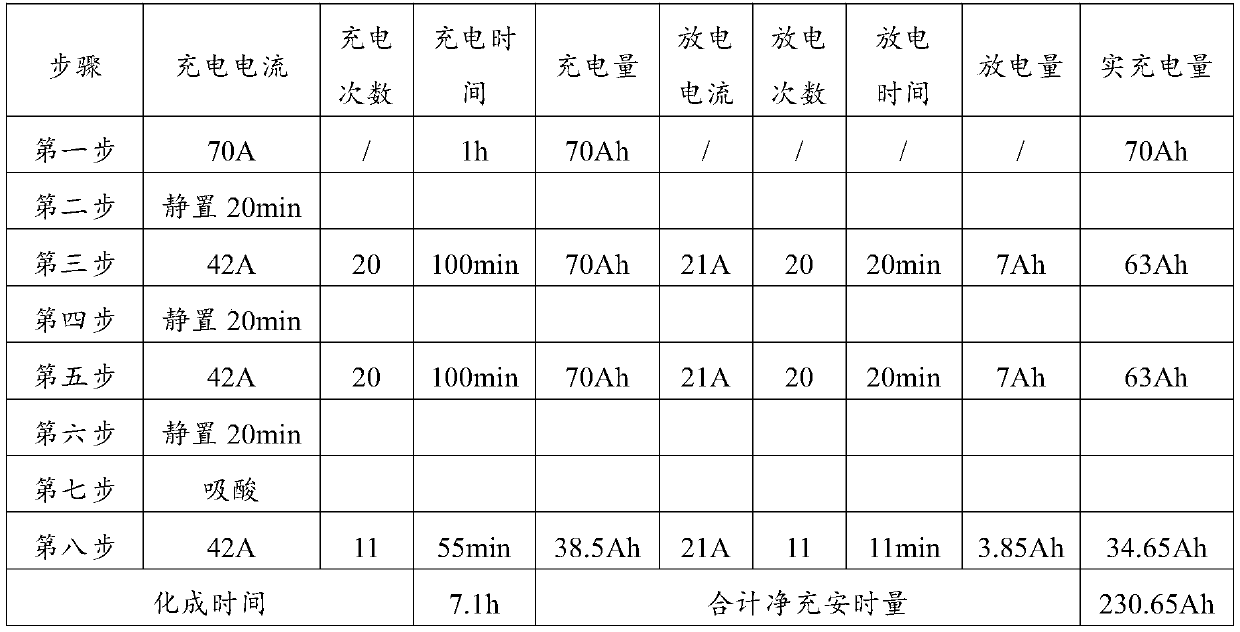

[0043] Taking the battery 6-QW-70Ah (L3) as an example, the total charging ampere-hour is confirmed according to 3.3 times the actual capacity of the battery, that is, the total charging ampere-hour is 70Ah×3.3=231Ah, and the number of times of charging in the last step is N=nC / 4.5I , wherein, I=70, C=231, n=15, then N=11, and the number of discharges in the last step is also 11 times.

[0044] Internalize the battery 6-QW-70Ah (L3) into a charging and discharging method, the steps are as follows:

[0045] 1. Separator type selection: choose a separator with a size of 240×162×2.87 (10KPa), and use 5 separators to cover the positive plate for each grid;

[0046] 2. Add dilute sulfuric acid to the battery as the electrolyte, and the specific gravity of dilute sulfuric acid is 1.245±0.005g / cm 3 (25°C);

[0047] 3. Charge and discharge according to the following procedure:

[0048] The first step: 70A charging for 1h, constant current charging, no discharge, then the charging a...

Embodiment 2

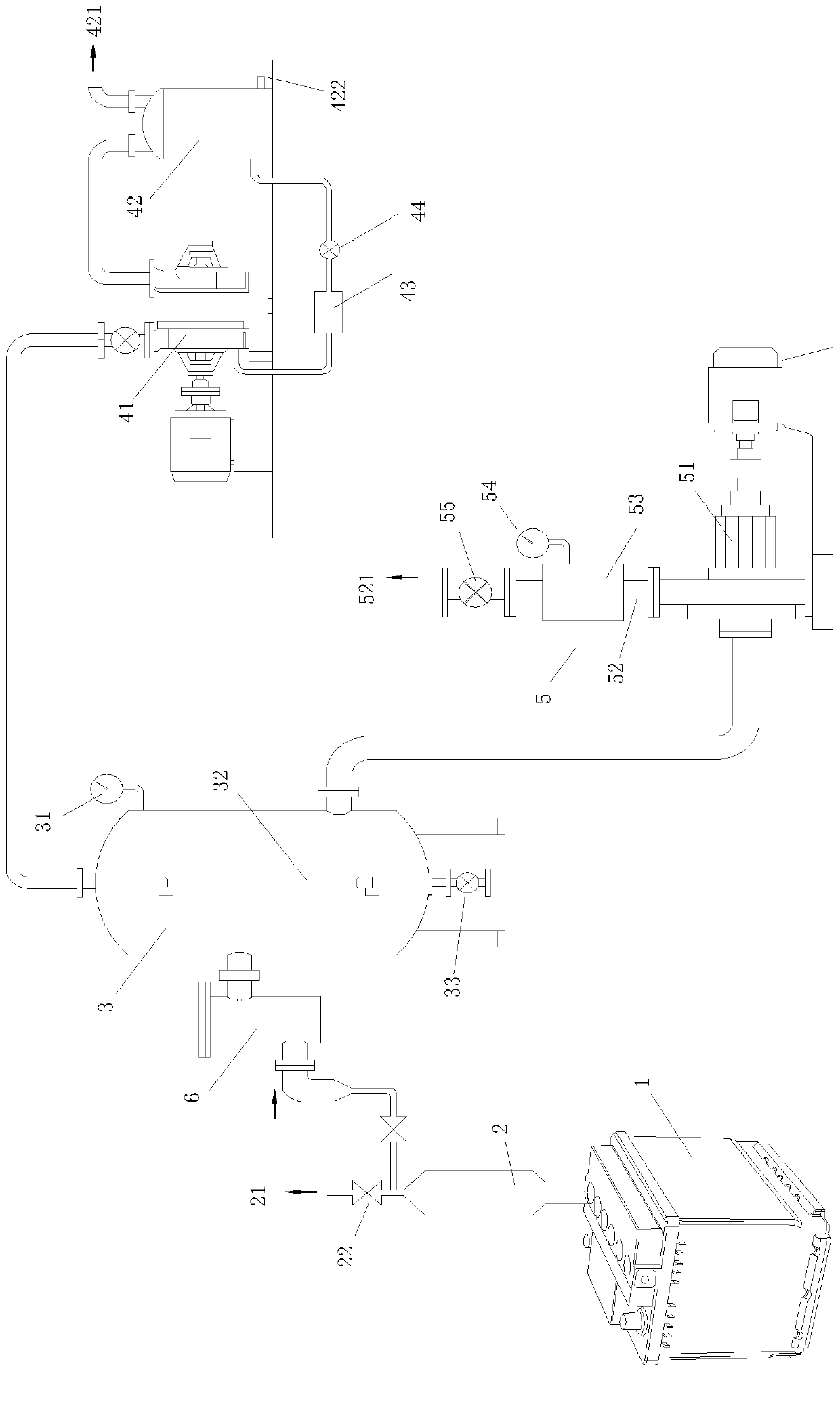

[0083] The schematic diagram of the device structure for realizing the above-mentioned vacuum pumping acid is as follows: figure 2 as shown, figure 2 The direction pointed by the middle arrow indicates the flow direction of fluid (such as gas, liquid). The vacuum acid pumping device includes:

[0084] The rich liquid pot 2 ( figure 2 Only one liquid-rich pot is shown in the figure, in fact, the liquid-rich pot is closed and connected to each hole on the top of the battery 1), the top of the liquid-rich pot 2 is provided with a first exhaust port 21, and the top of the liquid-rich pot 2 is close to the first exhaust port The port 21 section is provided with a stop valve 22 that determines the opening and closing of the first exhaust port 21;

[0085] The vacuum tank 3 connected with the upper part of the rich liquid pot 2 through a pipeline, the outer wall of the vacuum tank 3 is connected with a vacuum gauge 31 for monitoring the vacuum degree inside the vacuum tank 3; a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com