Hard coating film

A technology of hard coating film and inorganic particles, used in coatings, instruments, layered products, etc., can solve the problems of difficult to control the uniform formation of unevenness and poor anti-blocking performance, and achieve excellent physical properties, excellent optical properties and anti-blocking properties. effect of function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

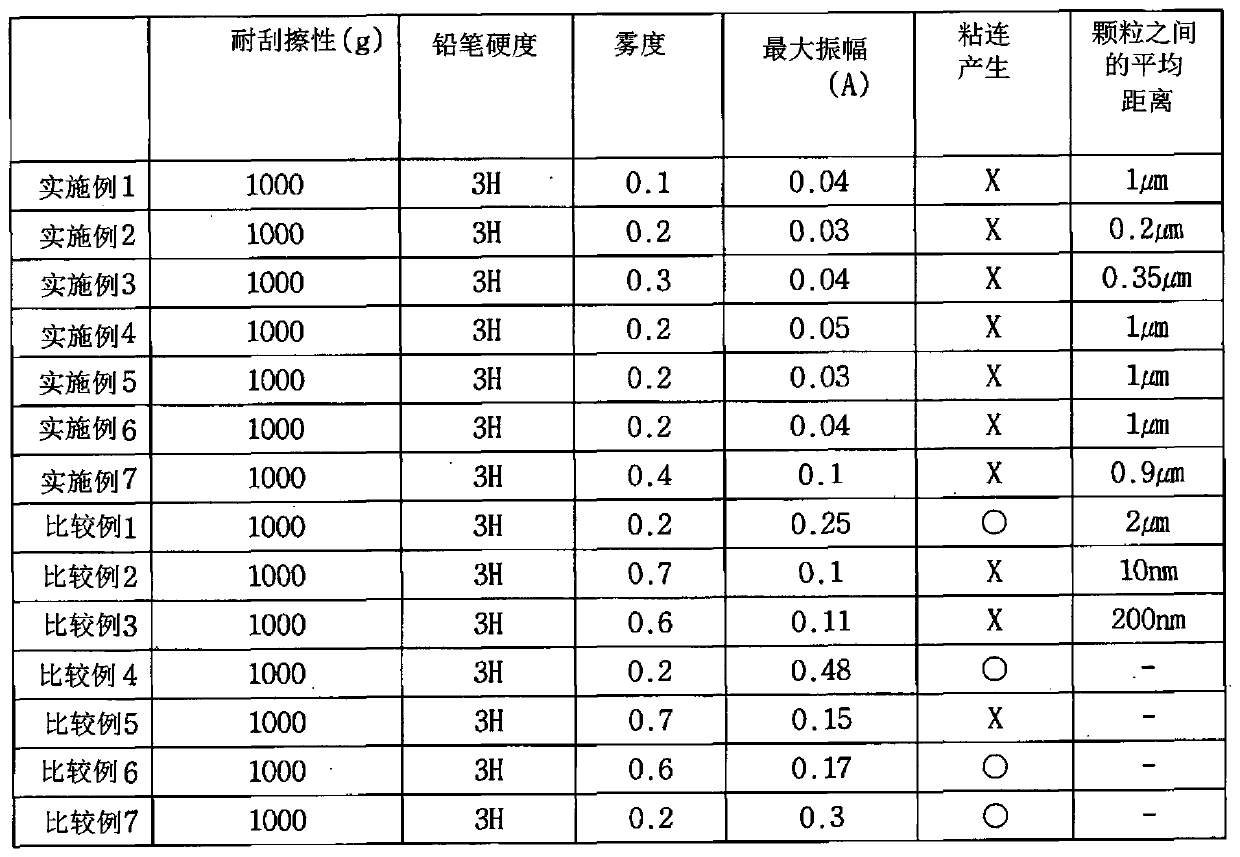

Embodiment 1

[0059] 91 g of pentaerythritol triacrylate (PETA), 3 g of first silica particles (surface treatment: 3-methacryloxypropylmethyldimethoxysilane) with an average particle size of 23 nm, 4 g of average particle size 132nm second silica particles (surface treatment: 3-methacryloxypropylmethyldimethoxysilane), 0.05g fluorine-based acrylate (RS-537, DIC) and 1.95g light The solid component of the initiator (Irgacure 184, Ciba) was diluted to a solid concentration of 45% by weight in a MEK (methyl ethyl ketone) solvent to prepare a composition for the base layer.

[0060] Coat a triacetylcellulose film with this composition using a #10 Mayer rod, dry at 60°C for 1 min, and 2 The dose is irradiated to produce a hard coat film with a thickness of about 5 μm to about 6 μm.

Embodiment 2

[0062]80 g of pentaerythritol triacrylate (PETA), 7 g of first silica particles (surface treatment: 3-methacryloxypropylmethyldimethoxysilane) with an average particle size of 15 nm, 11 g of average particle size 110nm second silica particles (surface treatment: 3-methacryloxypropylmethyldimethoxysilane), 0.1g fluorine-based acrylate (RS-537, DIC) and 1.9g light The solid component of the initiator (Irgacure 184, Ciba) was diluted to a solid concentration of 44% by weight in a MEK (methyl ethyl ketone) solvent to prepare a composition for the base layer.

[0063] A hard coat film was produced in the same manner as in Example 1 using the above composition.

Embodiment 3

[0065] 85 g of pentaerythritol triacrylate (PETA), 4 g of first silica particles (surface treatment: 3-methacryloxypropylmethyldimethoxysilane) with an average particle size of 23 nm, 9 g of average particle size 132nm second silica particles (surface treatment: 3-methacryloxypropylmethyldimethoxysilane), 0.05g fluorine-based acrylate (RS-537, DIC) and 1.95g light The solid component of the initiator (Irgacure 184, Ciba) was diluted to a solid concentration of 44% by weight in a MEK (methyl ethyl ketone) solvent to prepare a composition for the base layer.

[0066] A hard coat film was produced in the same manner as in Example 1 using the above composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com