Beef tallow hotpot condiment and preparation method thereof

A technology of hot pot bottom material and butter, which is applied in food science and other fields, can solve problems such as easy to get angry, and achieve the effect of reducing the possibility of getting angry, reducing irritation, and enriching the taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

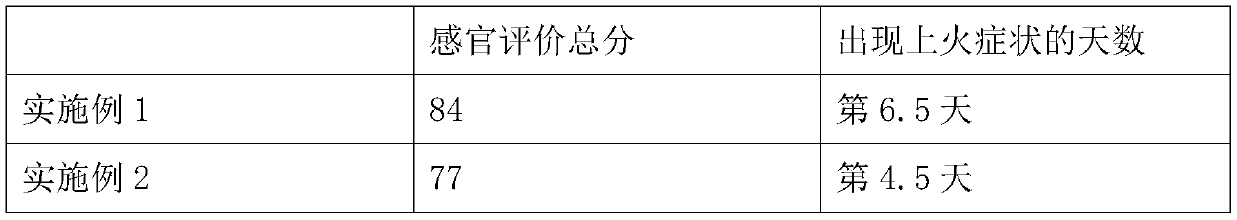

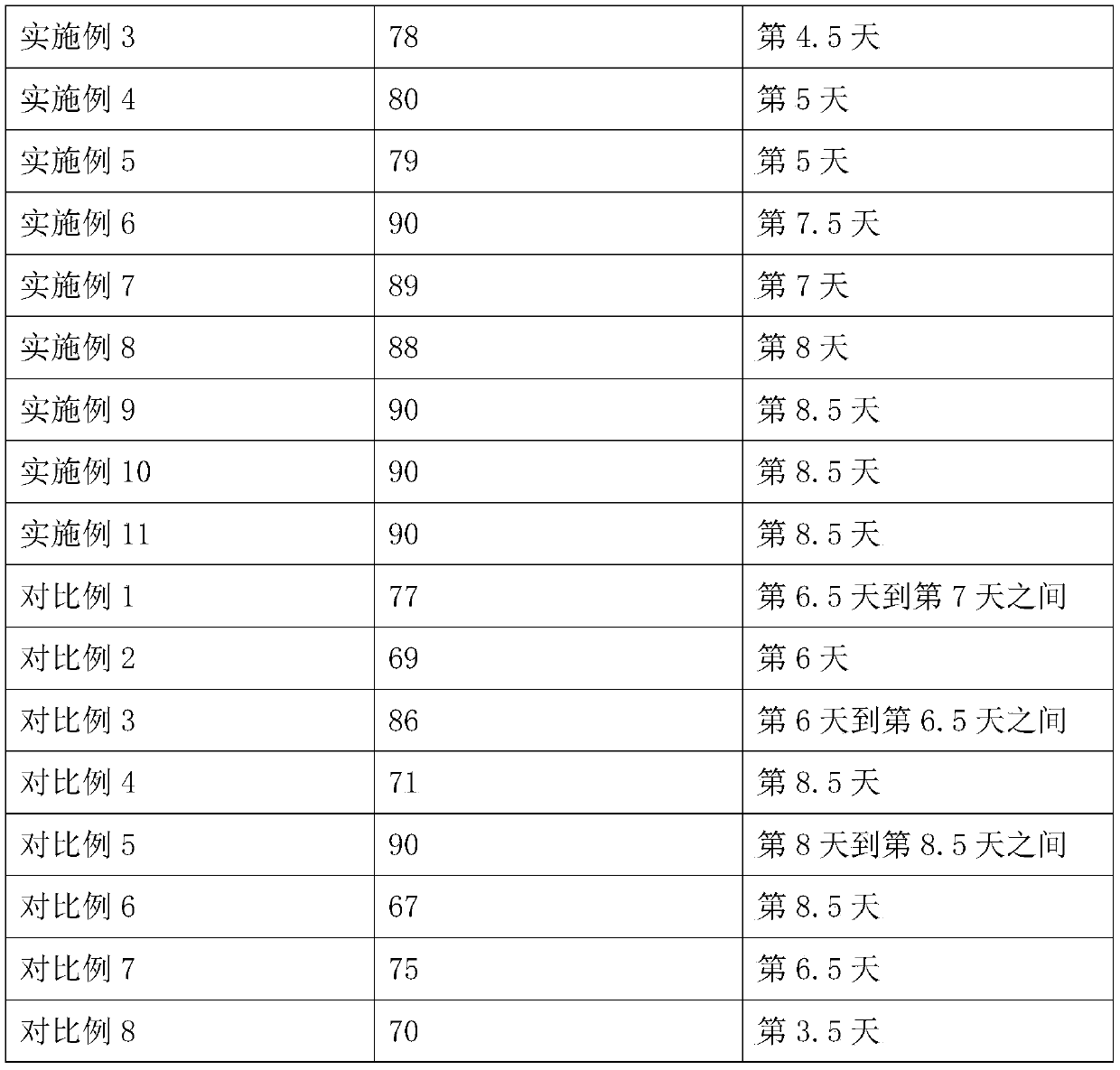

Examples

Embodiment 1

[0049] A kind of butter hot pot bottom material and preparation method thereof, by weight, comprises following components:

[0050] Main ingredients: 1450 parts of butter, 980 parts of vegetable oil, 980 parts of Pixian bean paste, 100 parts of glutinous rice cake pepper, 110 parts of fermented pepper, 96 parts of fermented glutinous rice, 90 parts of tempeh. At this time, the ratio of fermented pepper to glutinous rice cake pepper is 1:0.9 .

[0051] Seasoning: 76 parts of peeled ginger, 68 parts of garlic, 42 parts of onion, 12 parts of monosodium glutamate, 90 parts of salt, 40 parts of rock sugar, 6 parts of white wine;

[0052] Accessories: 10 parts of pepper, 8 parts of cinnamon, 7 parts of grass fruit, 6 parts of clove, 5 parts of lemongrass, 6 parts of nutmeg, 5 parts of three Nye, 5 parts of vanilla, 5 parts of thyme, 5 parts of fragrant leaves, 5 parts of star anise , 5 parts of tangerine peel, 5 parts of licorice, 2 parts of dried hawthorn, 5 parts of Luo Han Guo, 5 ...

Embodiment 2

[0066] The difference from Example 1 is: main ingredients: 1400 parts of butter, 950 parts of vegetable oil, 900 parts of Pixian bean paste, 40 parts of glutinous rice cake pepper, 60 parts of fermented pepper, 85 parts of fermented glutinous rice, 80 parts of tempeh, fermented at this time The ratio of pepper to glutinous rice cake pepper is 1:0.6.

[0067] Seasoning: 72 parts of peeled ginger, 60 parts of garlic, 30 parts of onion, 10 parts of monosodium glutamate, 80 parts of salt, 30 parts of rock sugar, 5 parts of white wine;

[0068] Accessories: 8 parts of peppercorns, 7 parts of cinnamon, 6 parts of grass fruit, 5 parts of cloves, 4 parts of lemongrass, 4 parts of nutmeg, 4 parts of three Nye, 4 parts of vanilla, 4 parts of thyme, 4 parts of fragrant leaves, 4 parts of star anise , 4 parts of tangerine peel, 4 parts of licorice, 1 part of dried hawthorn, 4 parts of Luo Han Guo, 4 parts of Polygonatum odoratum;

[0069] The processing method of fermented pepper is:

...

Embodiment 3

[0082] The difference with embodiment 1 is: the difference with embodiment 1 is:

[0083] Main ingredients: 1600 parts of butter, 1100 parts of vegetable oil, 1100 parts of Pixian bean paste, 170 parts of glutinous rice cake pepper, 120 parts of fermented pepper, 115 parts of fermented glutinous rice, 110 parts of tempeh. At this time, the ratio of fermented pepper to glutinous rice cake pepper is 1:1.4 .

[0084] Seasoning: 85 parts of peeled ginger, 78 parts of garlic, 60 parts of green onion, 5 parts of monosodium glutamate, 130 parts of table salt, 70 parts of rock sugar, 10 parts of white wine;

[0085] Accessories: 12 parts of pepper, 10 parts of cinnamon, 8 parts of grass fruit, 8 parts of clove, 6 parts of lemongrass, 7 parts of nutmeg, 6 parts of three Nye, 6 parts of vanilla, 6 parts of thyme, 6 parts of fragrant leaves, 6 parts of star anise , 6 parts of tangerine peel, 6 parts of licorice, 3 parts of dried hawthorn, 8 parts of Luo Han Guo, 7 parts of Polygonatum o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com