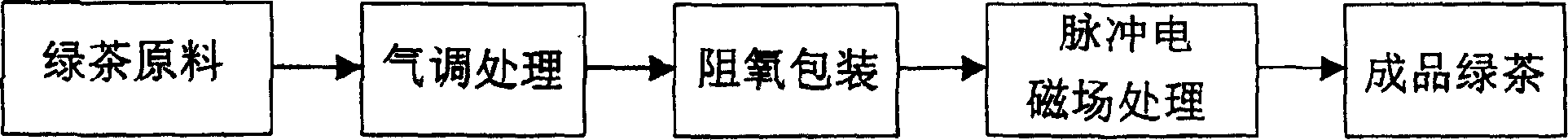

Normal temperature fresh-keeping processing method of green tea

A processing method and technology of green tea, which are applied in the processing field of green tea fresh-keeping at room temperature, can solve problems such as unsolved storage problems of green tea, failure to achieve green tea storage at room temperature, and unsatisfactory fresh-keeping effect, so as to improve green tea grade and social and economic efficiency, avoid Dissipation and odor, the effect of convenient source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In this embodiment, 120 kg of Biluochun Mingqian tea is taken and packed into a packaging bag made of 0.07mm aluminum foil. Then the mixed gas with a volume percentage of 10 parts of nitrogen and a volume percentage of 90 parts of carbon dioxide is filled into an aluminum foil packaging bag through a pipeline for modified atmosphere treatment, and the oxygen content of the modified atmosphere treatment is 0.4%. This not only reduces the nitrogen content, but also maintains the integrity of the tea. After the modified atmosphere treatment, the packaging bag is sealed with a heat-sealing packaging machine, thereby realizing the oxygen barrier packaging and isolating the contact between the tea and oxygen. After the packaging bag is sealed, the electromagnetic waves generated by the pulse electromagnetic wave generator are used to irradiate the packaged green tea raw materials for 30 minutes, thereby inhibiting the activities of various oxidases in the green tea. The puls...

Embodiment 2

[0023] Take 300 kilograms of Wuxi Haocha Mingqian tea, the thickness of the aluminum foil packaging bag is 0.07mm, the volume percentage of nitrogen gas is 20 parts, the volume percentage of carbon dioxide is 80 parts during the controlled atmosphere treatment, and the oxygen content of the controlled atmosphere treatment is 0.3%; use pulsed electromagnetic waves Irradiate for 30 minutes with a voltage of 187V, a field strength of 20V / cm, a frequency of 300Hz, and a pulse width of 50ns. After 12 months of green tea made by the processing method in Example 1, the retention rate of chlorophyll reached 91%, the retention rate of vitamin C was 93.5%, the retention rate of tea polyphenols was 96.2%, the retention rate of free amino acids was 99%, and the aroma The retention rate was 91.9%.

Embodiment 3

[0025] Take 80 kg of Biluochun Mingqian tea, the thickness of the aluminum foil packaging bag is 0.07mm, the volume percentage of argon in the inert gas is 100 parts, and the oxygen content of the modified atmosphere is 0.3%; the pulse electromagnetic wave is irradiated for 30 minutes, the voltage is 187V, the field strength 20V / cm, frequency 300Hz, pulse width 50ns. After 12 months, the green tea made by the processing method in Example 1 and Example 2 had a chlorophyll retention rate of 89.1%, a vitamin C retention rate of 93.2%, a tea polyphenol retention rate of 96.9%, and a free amino acid retention rate of 96.9%. 99.4%, and the aroma retention rate is 92.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com