Chlorosilane and high polymer leakage cleaning system

A polymer and chlorosilane technology, which is applied in the field of chlorosilane and polymer leakage cleaning systems, can solve problems such as normal production and production safety hazards, blockage of equipment and waste discharge lines, corrosion of equipment and pipelines, and achieve compact structure , Reduce material waste and avoid clogging problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

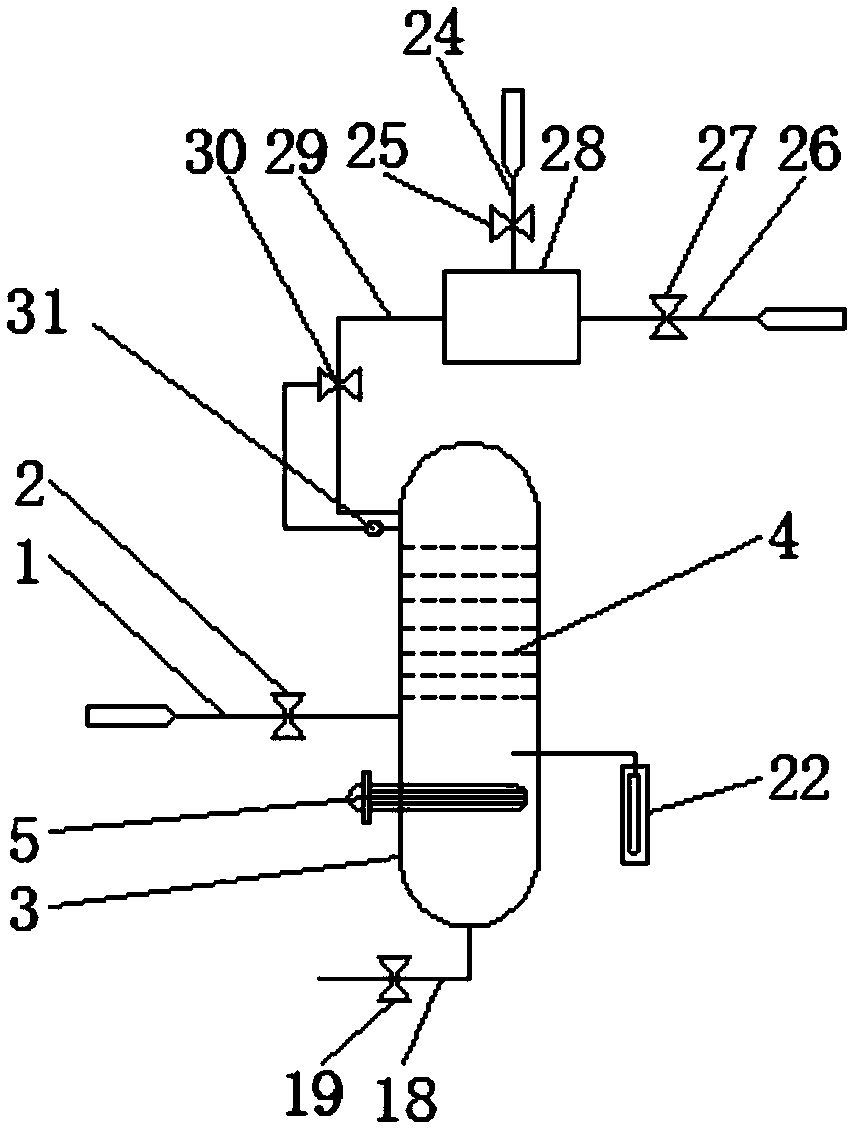

Embodiment 1

[0029] Such as figure 1 As shown, this implementation provides a chlorosilane and high polymer leakage cleaning system, which includes a washing tower 3 and a sodium edetate liquid mixing tank 28; the washing tower 3 is used to feed the leaked material The pipeline 1 enters the chlorosilane and high polymer in the washing tower 3 for treatment, the leaked material feeding pipeline 1 is provided with a feed valve 2, and the washing tower 3 is provided with a first tray 4 and a first re- Boiler 5, the first reboiler 5 uses a tank type reboiler, the first thermometer 22 is arranged on the washing tower 3, the first waste line 18 is arranged at the bottom of the washing tower 3, and the first waste line 18 is arranged at the bottom of the washing tower 3. A waste discharge line 18 is provided with a first waste discharge valve 19; the sodium ethylenediaminetetraacetate liquid mixing tank 28 is used to configure the sodium edetate liquid for cleaning chlorosilanes and high polymers...

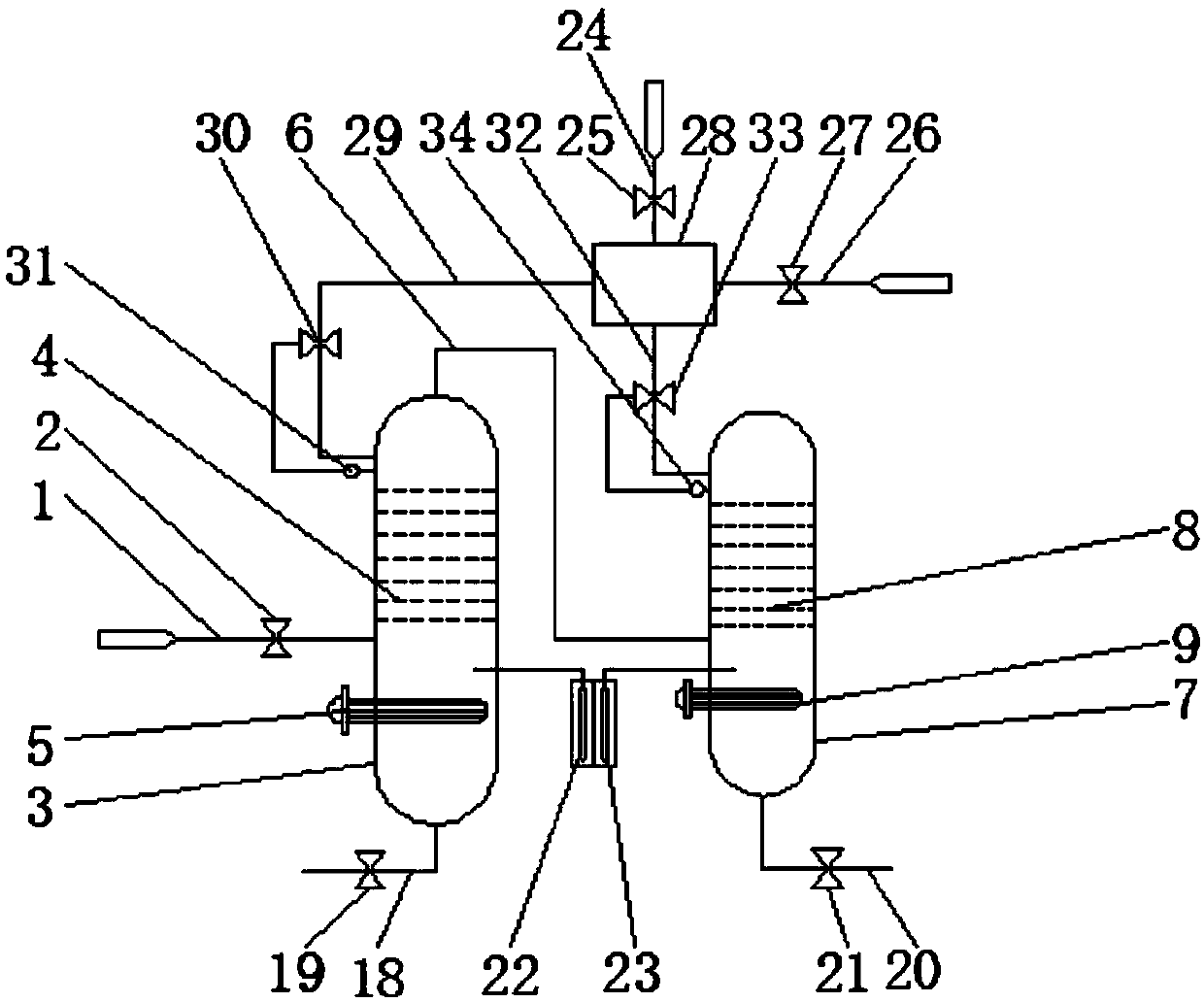

Embodiment 2

[0032] Such as figure 2As shown, this implementation provides a chlorosilane and high polymer leakage cleaning system, which includes a washing tower 3, a sodium edetate liquid mixing tank 28 and a distillation tower 7; the washing tower 3 is used to pass through The leaked material feed line 1 enters the chlorosilane and high polymer in the washing tower 3 for treatment, the leaked material feed line 1 is provided with a feed valve 2, and the washing tower 3 is provided with a first tray 4 and the first reboiler 5, the first reboiler 5 uses a kettle-type reboiler, the washing tower 3 is provided with a first thermometer 22, and the washing tower 3 bottom is provided with a first waste line 18 , the first waste discharge pipeline 18 is provided with a first waste discharge valve 19; the sodium edetate liquid mixing tank 28 is used to configure the sodium edetate liquid for cleaning chlorosilanes and polymers, The top of the sodium edetate liquid mixing tank 28 is provided wi...

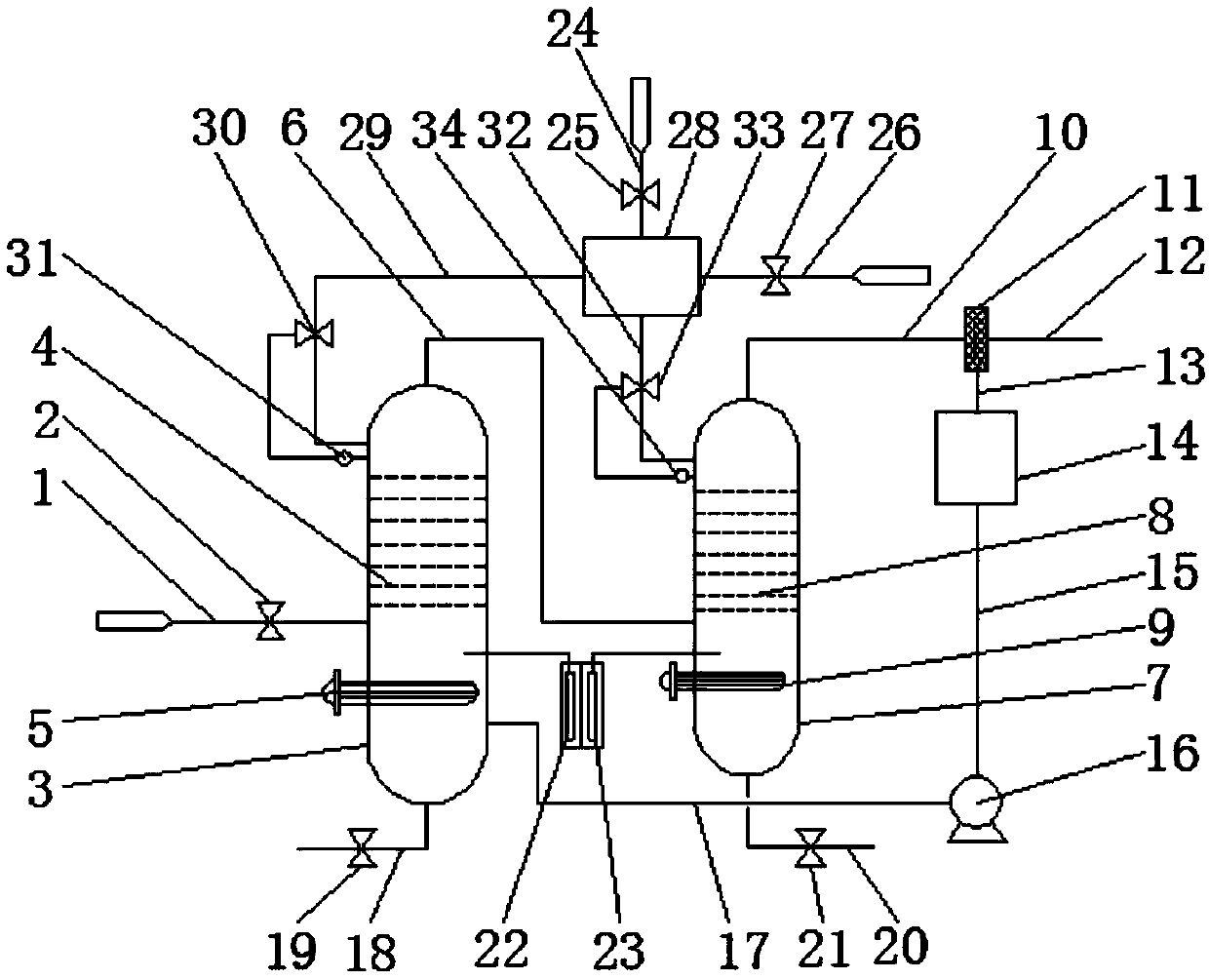

Embodiment 3

[0035] Such as image 3 As shown, this implementation provides a chlorosilane and high polymer leakage cleaning system, which includes a washing tower 3, a sodium edetate liquid mixing tank 28, a distillation tower 7, a gas filter 11, a condensation tank 14 and Reflux pump 16; the washing tower 3 is used to process the chlorosilane and high polymers that enter the washing tower 3 through the leaked material feed line 1, and the leaked material feed line 1 is provided with a feed valve 2, The washing tower 3 is provided with a first tray 4 and a first reboiler 5, and the first reboiler 5 uses a kettle-type reboiler, and the washing tower 3 is provided with a first thermometer 22, so The bottom of the washing tower 3 is provided with a first waste discharge pipeline 18, and the first waste discharge pipeline 18 is provided with a first waste discharge valve 19; the sodium edetate liquid mixing tank 28 is used to configure and clean up chlorosilane and the sodium edetate liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com