Fodder raw material crushing equipment capable of realizing intermittent feeding and discharging and application method of fodder raw material crushing equipment

A technology for processing equipment and raw materials, applied in the field of feed raw material crushing and processing equipment with intermittent feeding and discharging, can solve the problems of pipeline blockage, difficult maintenance, unreasonable and imperfect design, etc., to accelerate feeding, avoid blockage, and facilitate independent control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

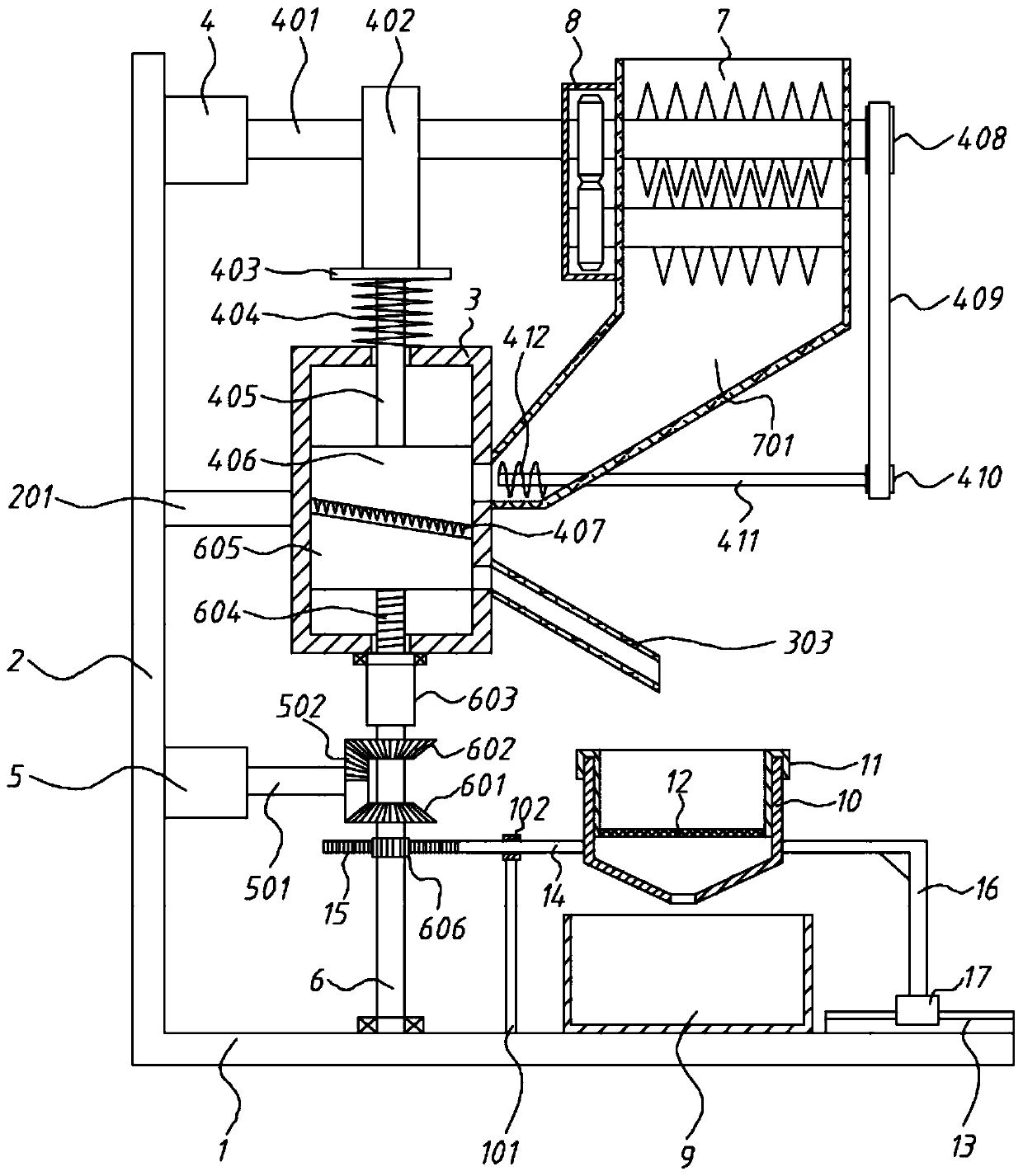

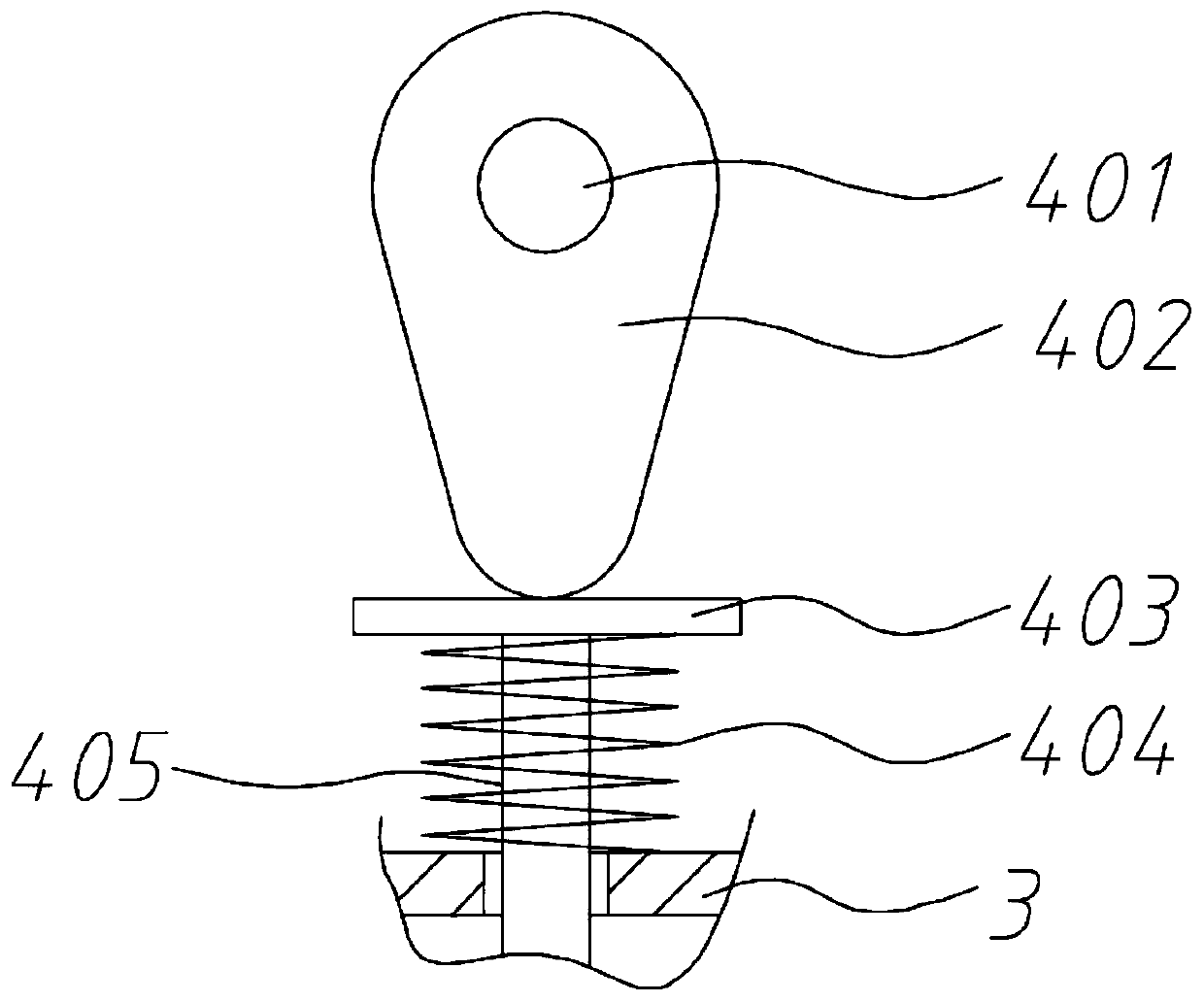

[0045] Feed raw material crushing and processing equipment capable of feeding and discharging intermittently, including bracket, No. 1 servo motor 4, cam assembly, crushing chamber 3, No. 2 servo motor 5, bevel gear assembly, feeding hopper 7, feeding pipe 303 and receiving basket 9;

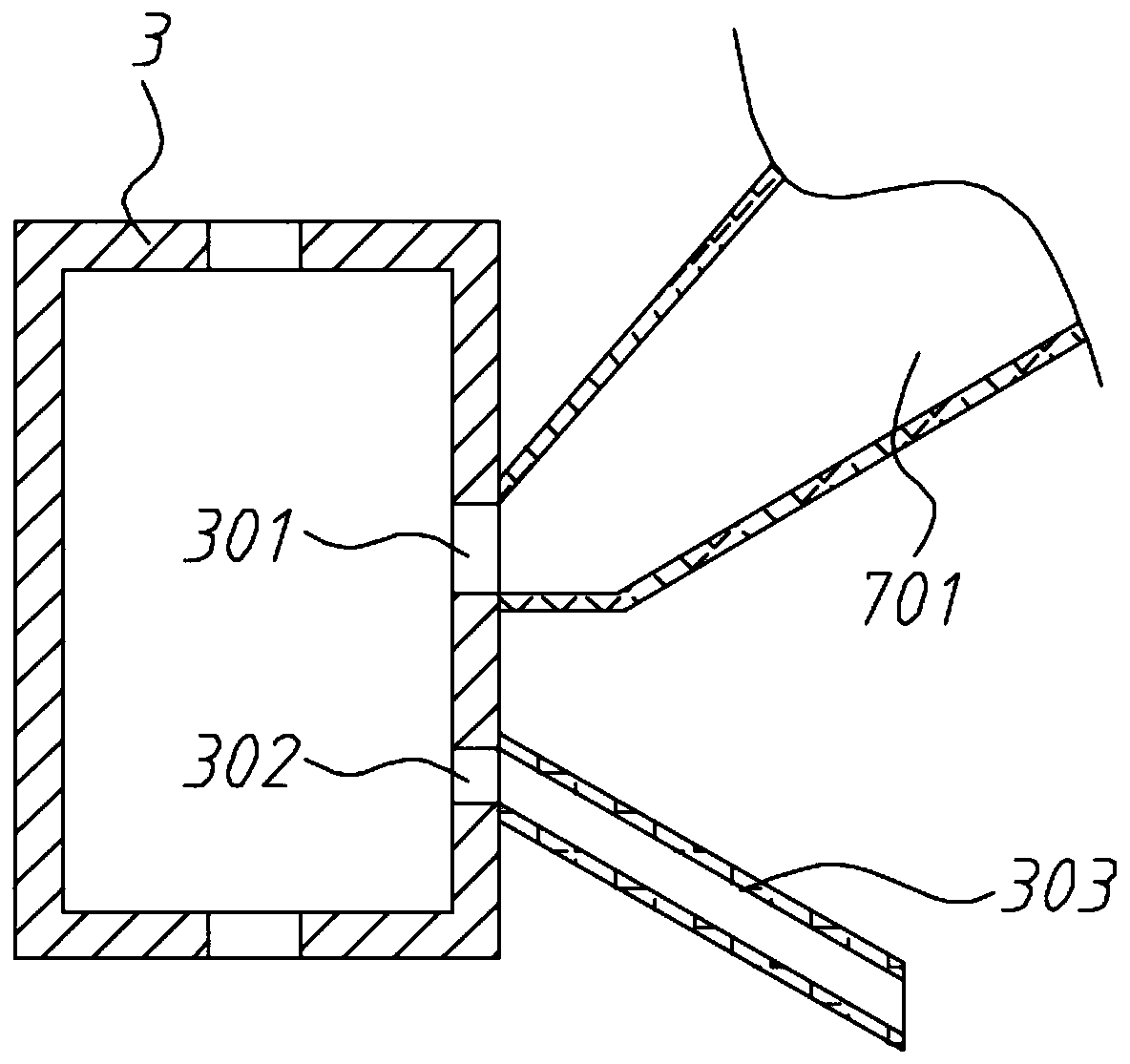

[0046] The bracket includes a base 1 and a vertical vertical plate 2 fixed on the left end of the base 1; the crushing chamber 3 is connected to the right side of the vertical plate 2 through the second pole 201; the upper pressing head 406 and the lower pressing head 605 are arranged in the crushing chamber ; The bottom surface of the upper pressing head 406 and the top surface of the lower pressing head 605 are corresponding slopes with high left and low right;

[0047] The feeding hopper 7 is arranged on the upper right of the crushing chamber 3, and the bottom of the feeding hopper 7 is connected with a guide hopper 701, which communicates with the feed port 301 opened on the right side wall...

Embodiment 2

[0053] Feed raw material crushing and processing equipment capable of feeding and discharging intermittently, including bracket, No. 1 servo motor 4, cam assembly, crushing chamber 3, No. 2 servo motor 5, bevel gear assembly, feeding hopper 7, feeding pipe 303 and receiving basket 9;

[0054] The bracket includes a base 1 and a vertical vertical plate 2 fixed on the left end of the base 1; the crushing chamber 3 is connected to the right side of the vertical plate 2 through the second pole 201; the upper pressing head 406 and the lower pressing head 605 are arranged in the crushing chamber ; The bottom surface of the upper pressing head 406 and the top surface of the lower pressing head 605 are corresponding slopes with high left and low right;

[0055] The feeding hopper 7 is arranged on the upper right of the crushing chamber 3, and the bottom of the feeding hopper 7 is connected with a guide hopper 701, which communicates with the feed port 301 opened on the right side wall...

Embodiment 3

[0061] Feed raw material crushing and processing equipment capable of feeding and discharging intermittently, including bracket, No. 1 servo motor 4, cam assembly, crushing chamber 3, No. 2 servo motor 5, bevel gear assembly, feeding hopper 7, feeding pipe 303 and receiving basket 9;

[0062] The bracket includes a base 1 and a vertical vertical plate 2 fixed on the left end of the base 1; the crushing chamber 3 is connected to the right side of the vertical plate 2 through the second pole 201; the upper pressing head 406 and the lower pressing head 605 are arranged in the crushing chamber ; The bottom surface of the upper pressing head 406 and the top surface of the lower pressing head 605 are corresponding slopes with high left and low right;

[0063] The feeding hopper 7 is arranged on the upper right of the crushing chamber 3, and the bottom of the feeding hopper 7 is connected with a guide hopper 701, which communicates with the feed port 301 opened on the right side wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com