High-efficiency uniform feeding, sieving and crushing system for polysilicon and monocrystalline silicon and method thereof

A crushing system, polysilicon technology, applied in the field of crushing system, high-efficiency polysilicon and single crystal silicon uniform feeding screening crushing, high-efficiency polysilicon and single crystal silicon uniform feeding screening crushing system field, can solve the problem of uneven feeding Crushing efficiency and other issues to achieve the effect of reducing scrap rate, avoiding local wear and improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

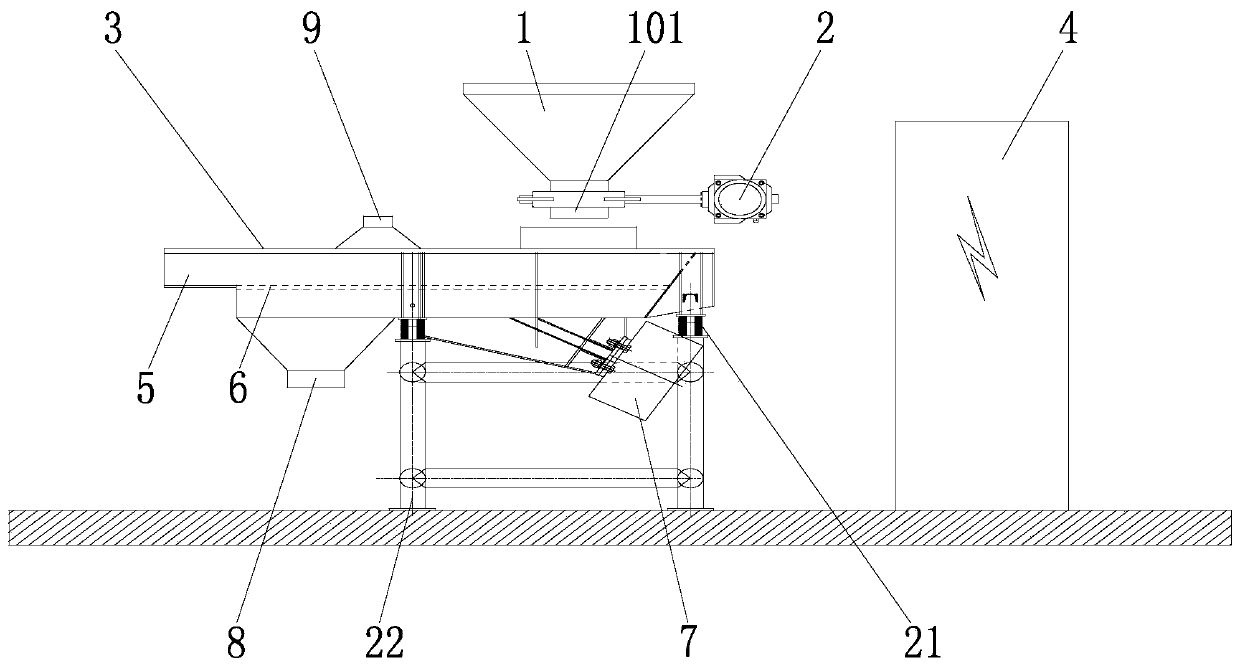

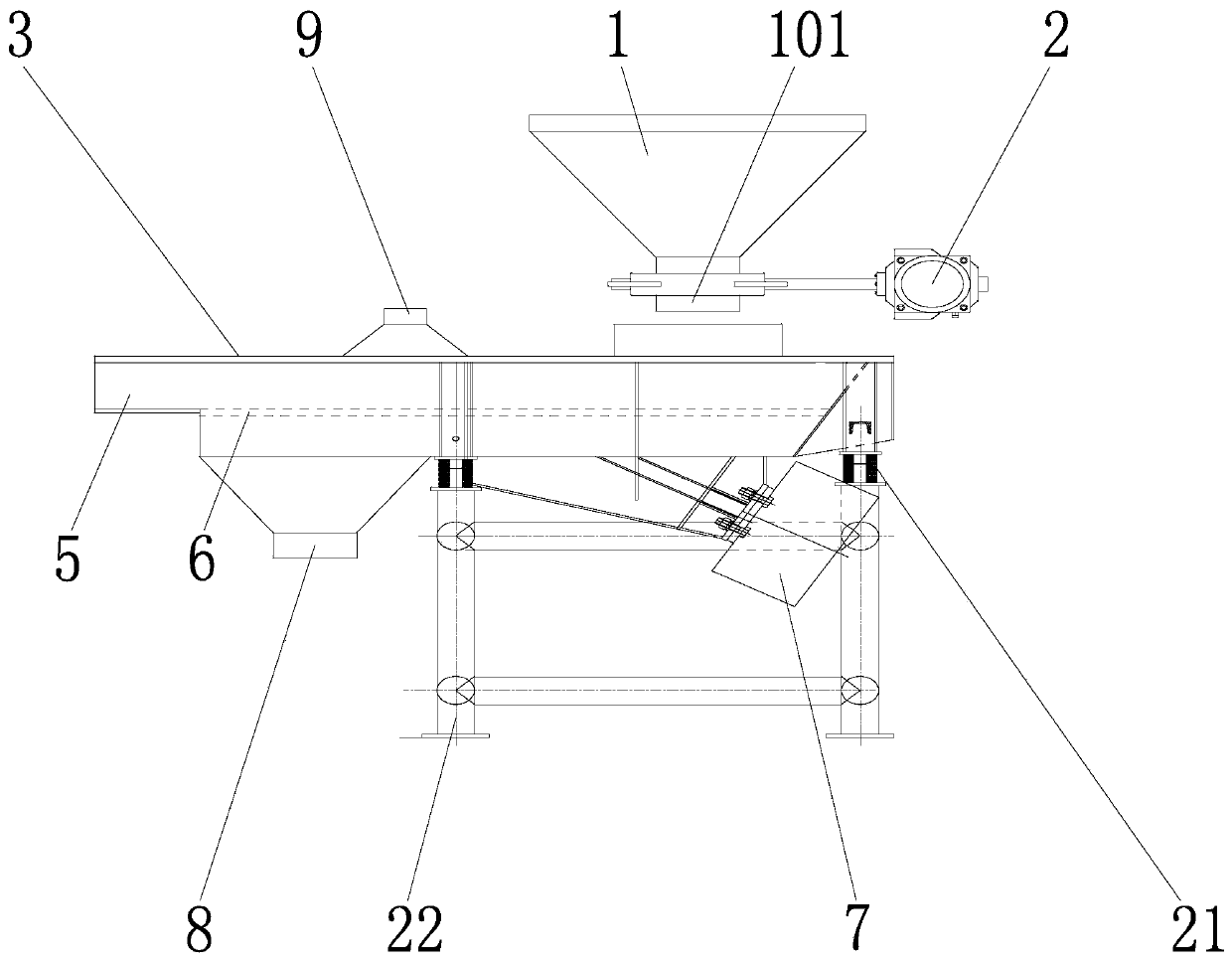

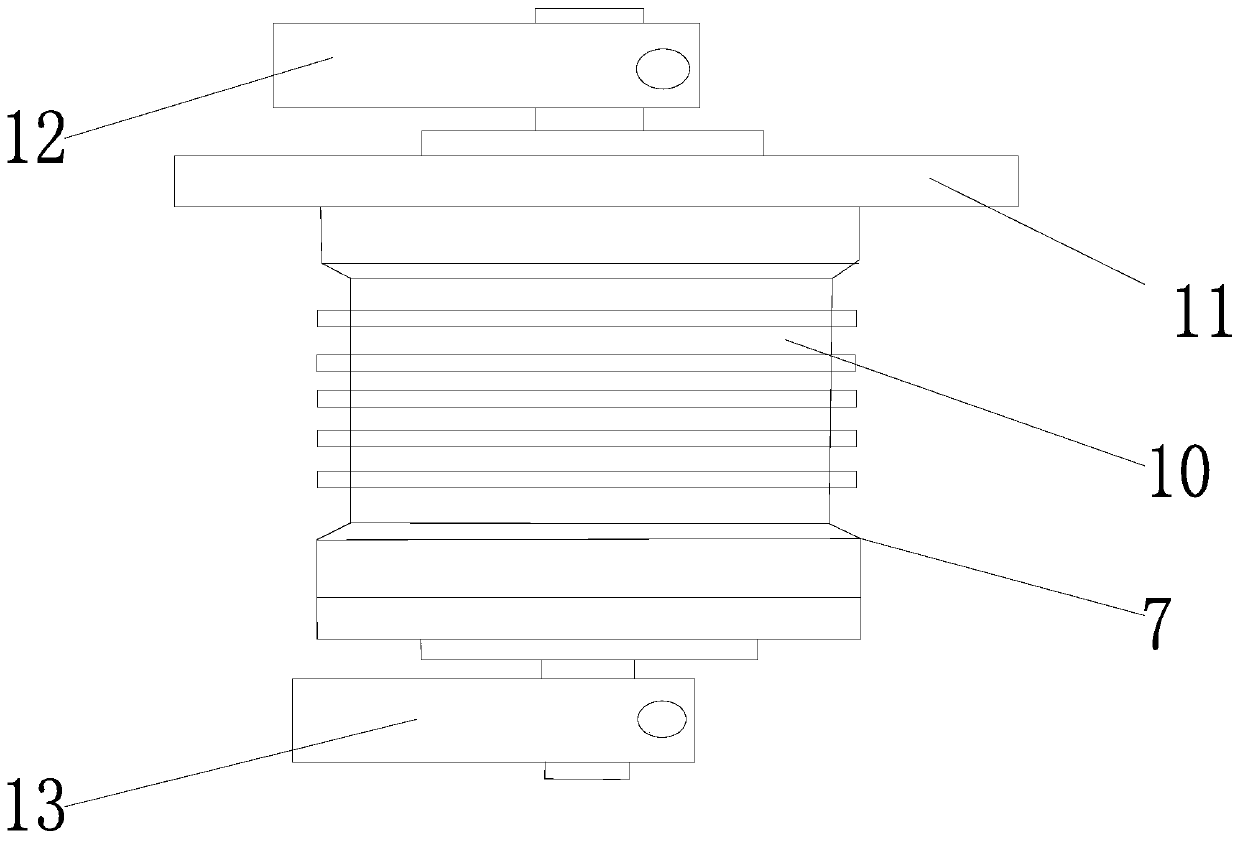

[0055] see figure 1 , this embodiment provides a high-efficiency polysilicon and monocrystalline silicon uniform feeding screening and crushing system, which can screen and crush silicon materials, and includes a silo 1, an electronic valve 2, a feeder 3, a crushing Machine, accumulation detection device and control subsystem.

[0056] The bottom of the silo 1 is provided with an upper outlet 101 for storing silicon materials. In this embodiment, the silo 1 is funnel-shaped, which can be fixed by structures such as support frames. When loading silicon material into the silo 1, a layer of polyurethane anti-collision film can be coated on the inner wall of the silo 1, so that on the one hand, the silo 1 can be protected; Scratches will not pollute the silicon material, thus ensuring the purity of the silicon material.

[0057] The electronic valve 2 is installed on the material bin 1 and is used to open or close the upper discharge port 101 . The electronic valve 2 can adjus...

Embodiment 2

[0070] see Figure 4 as well as Figure 5 , this embodiment provides a high-efficiency polysilicon and single crystal silicon uniform feeding screening and crushing system, which adds a sealing ring 14 on the basis of embodiment 1, and the sealing ring 14 belongs to the composition structure of the feeder 3 . The sealing ring 14 is installed on the lower discharge port 8, and is located in the groove provided by the lower discharge port 8, and is used to seal the connection between the feeder 3 and the crusher.

[0071] In this embodiment, the sealing ring 14 includes a sealing shell 15 and a spring one 16 . The first spring 16 is arranged in the sealing case 15 and adheres to the inner wall of the sealing case 15 . Wherein, the sealing shell 15 is made of polyurethane material, and the spring one 16 is made of stainless steel. After the sealing ring 14 is installed, the spring one 16 will be subjected to outward tension, so that the sealing lip is close to the sealing groo...

Embodiment 3

[0073] see Image 6 , this embodiment provides a high-efficiency polycrystalline silicon and single crystal silicon uniform feeding screening and crushing system, which adds a buffer device 18 on the basis of embodiment 1 or embodiment 2, and the buffer device 18 belongs to the feeder 3 composition structure. The buffer device 18 is arranged between the screen cloth 6 and the feeding box 5 , and is used to provide elastic force for the screen cloth 6 .

[0074]In this embodiment, each buffer device 18 includes a base 19 , a second spring 20 and a washer 23 . Base 19 is installed on the feeding box 5. One end of spring two 20 is installed on base 19, and the other end is connected with spacer 23. The spacer 23 is movably installed on the spacer 23 and is used to support the screen cloth 6 . The buffer device 18 is utilized. The elastic force of the spring 20 can well buffer the force caused by the vibration, thereby improving the service life of the screen 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com