Method capable of controlling uniform crystal and eliminating needle crystal

A technology for controlling and protecting acicular crystallization, applied in the field of iron and steel smelting and continuous casting, can solve the problems of undisclosed acicular crystals, uncommon, large workload, etc., and achieves short experimental operation time, simple operation and small workload. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

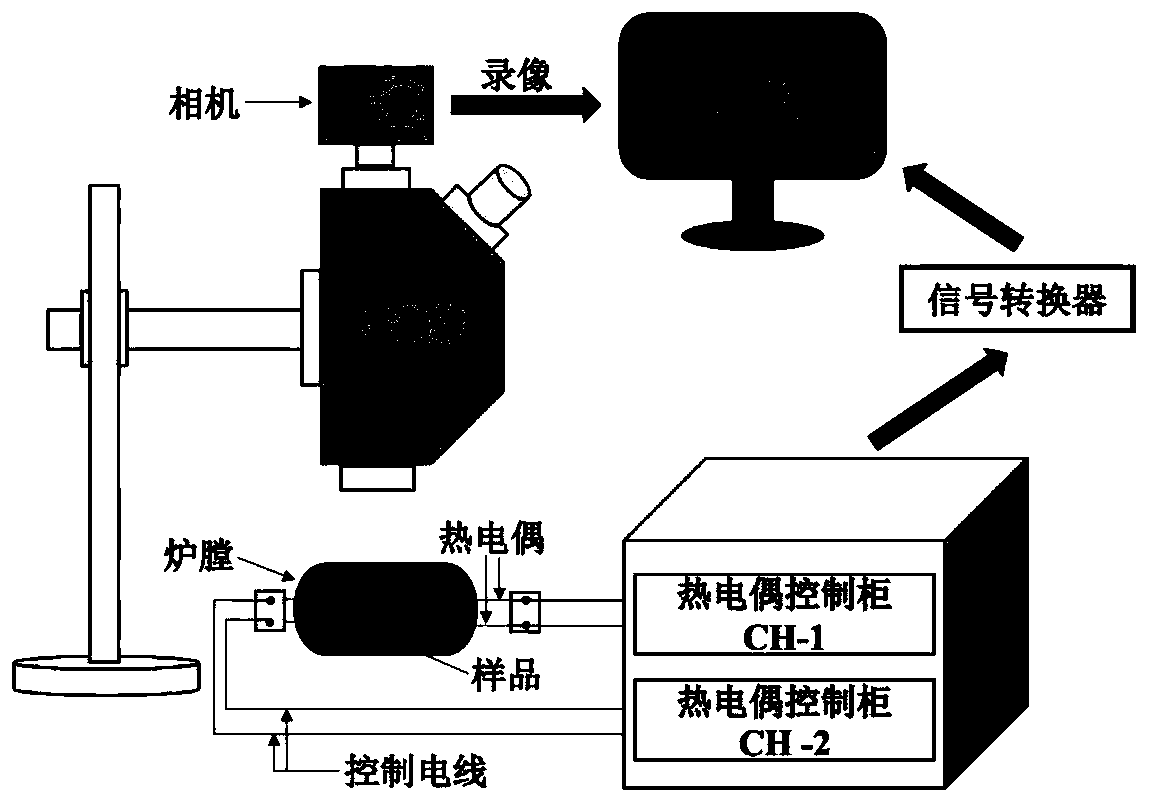

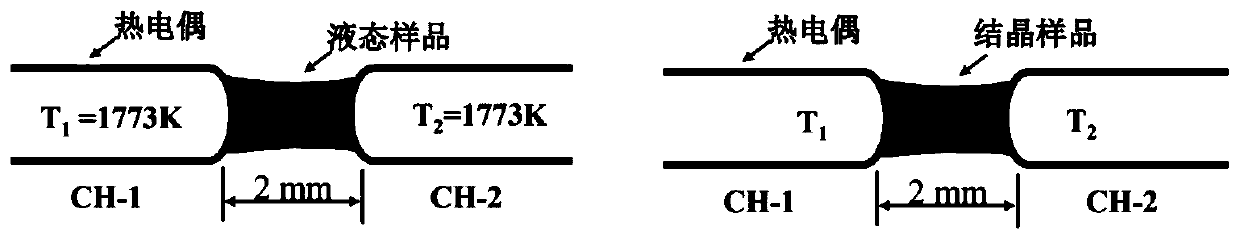

[0051] The experimental process of this example is to first mix the mold powder thoroughly and then grind it into powder; then pick the powder mold powder onto the thermocouple platinum rhodium wire, and then increase the temperature to 1773K at a heating rate of 15K / s to melt the mold powder, and keep it warm for 180s Eliminate air bubbles and uniform composition; then maintain the length of the liquid slag in the middle of the thermocouples at both ends at 2mm, and simultaneously lower the temperature of the thermocouples at both ends at a cooling rate of 30K / s to 1473K, and set the furnace temperature to 1473K while cooling , so that the furnace temperature and the temperature of the two thermocouples are the same, creating conditions for isothermal crystallization; after holding the temperature for 10 minutes to fully crystallize the liquid slag, turn off the temperature control system of the furnace and the two thermocouples at the same time, and remove the sample after coo...

Embodiment 2

[0053] The experimental process of this example is to first mix the mold powder thoroughly and then grind it into powder; then pick the powder mold powder onto the thermocouple platinum rhodium wire, and then increase the temperature to 1773K at a heating rate of 15K / s to melt the mold powder, and keep it warm for 180s Eliminate air bubbles and uniform composition; then maintain the length of the liquid slag in the middle of the thermocouples at both ends at 2mm, and simultaneously lower the temperature of the thermocouples at both ends at a cooling rate of 30K / s to 1273K, and set the furnace temperature to 1273K while cooling , so that the furnace temperature and the temperature of the two thermocouples are the same, creating conditions for isothermal crystallization; after holding the temperature for 10 minutes to fully crystallize the liquid slag, turn off the temperature control system of the furnace and the two thermocouples at the same time, and remove the sample after coo...

Embodiment 3

[0055] The experimental process of this example is to first mix the mold powder thoroughly and then grind it into powder; then pick the powder mold powder onto the thermocouple platinum rhodium wire, and then increase the temperature to 1773K at a heating rate of 15K / s to melt the mold powder, and keep it warm for 180s Eliminate air bubbles and uniform composition; then maintain the length of the liquid slag in the middle of the thermocouples at both ends at 2mm, and simultaneously lower the temperature of the thermocouples at both ends at a cooling rate of 30K / s to 1173K, and set the furnace temperature to 1173K while cooling , so that the furnace temperature and the temperature of the two thermocouples are the same, creating conditions for isothermal crystallization; after holding the temperature for 10 minutes to fully crystallize the liquid slag, turn off the temperature control system of the furnace and the two thermocouples at the same time, and remove the sample after coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com