Stainless steel composite plate of vacuum container and preparation method thereof

A vacuum container and stainless steel plate technology, which is applied in the field of steel plate composites, can solve the problems of high price, large vacuum container size, and container steel plate thickness, etc., and achieve the effects of reducing production costs, improving welding quality, and not easily deformed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

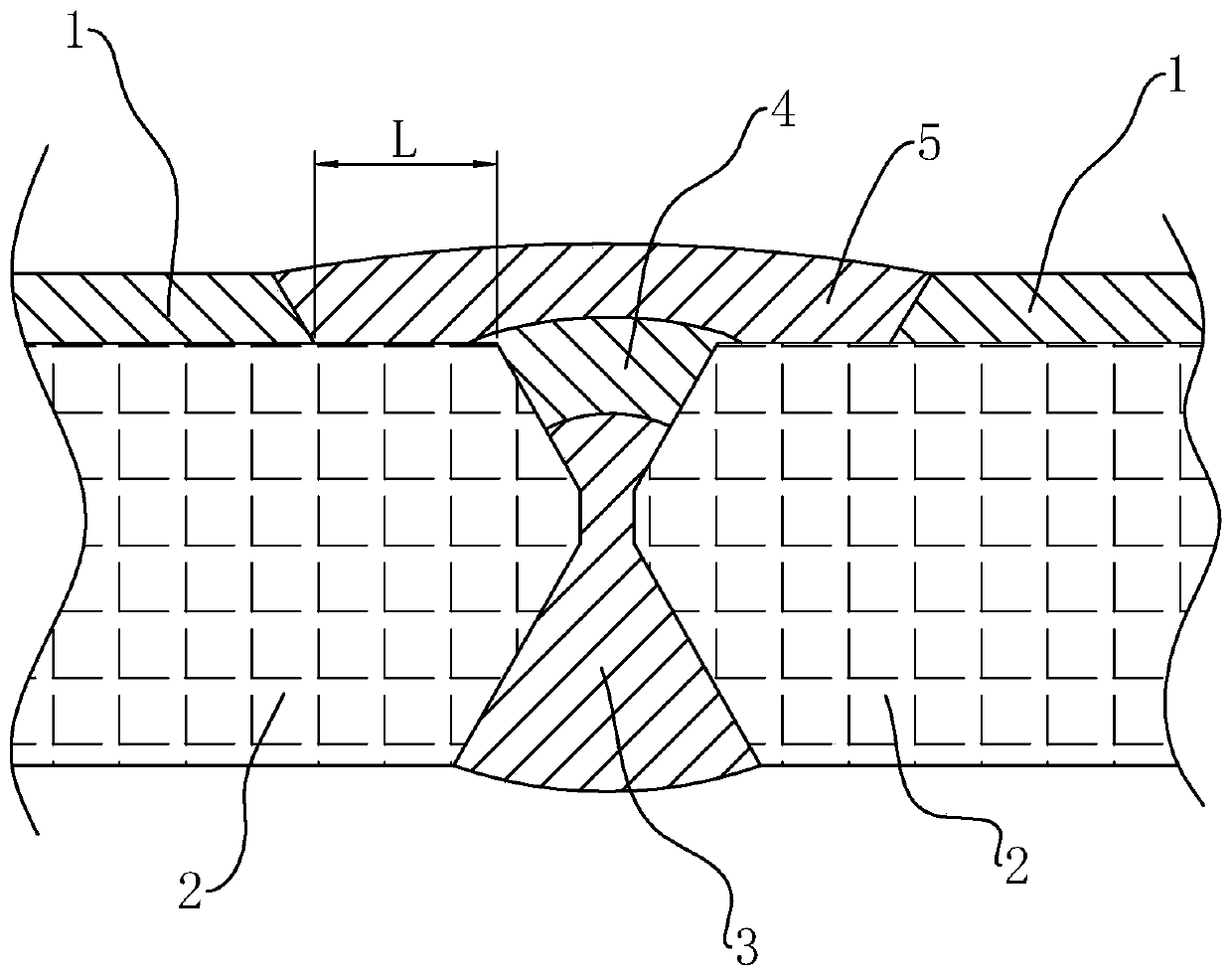

[0025] Embodiment 1: as figure 1 , the stainless steel clad plate for the vacuum vessel includes a carbon steel plate 2 and a stainless steel plate 1, the carbon steel plate 2 is located outside the vacuum vessel, and the stainless steel plate 1 is located inside the vacuum vessel. The carbon steel plate 2 has a thickness of 15-20 mm, the stainless steel plate 1 has a thickness of 2-3 mm, the stainless steel plate 1 is 304 stainless steel, and the carbon steel plate 2 is Q345R carbon steel.

[0026] The method for preparing a stainless steel composite plate for a vacuum vessel includes the following steps: step 1) processing the groove, the groove is X-shaped or V-shaped, preferably X-shaped in this embodiment, and the part of the stainless steel plate 1 close to the groove is cut off, The resection width L is 14mm; the carbon steel plate 2 and the stainless steel plate 1 are stacked up and down for welding positioning. The welding positioning refers to welding and positioning...

Embodiment 2

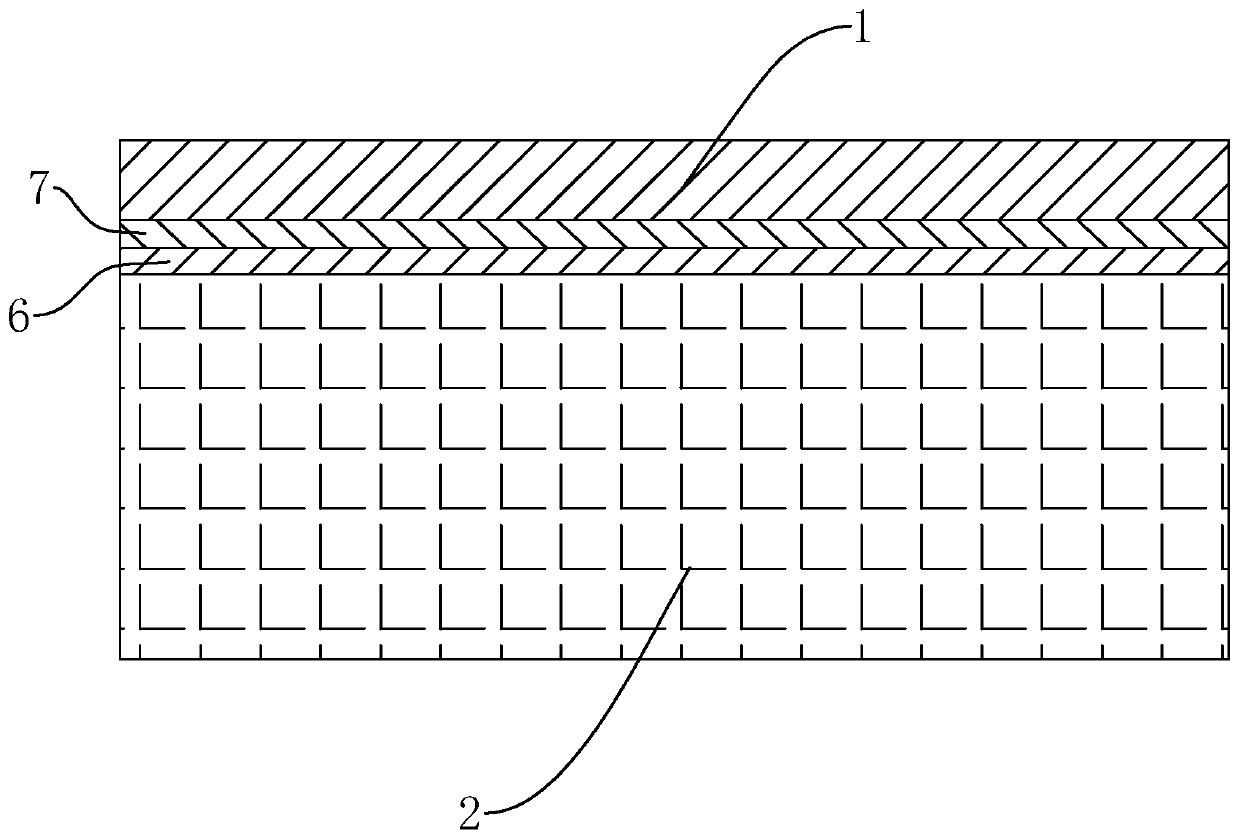

[0033] Embodiment 2: A stainless steel clad plate for a vacuum vessel, comprising a carbon steel plate 2 and a stainless steel plate 1, the carbon steel plate 2 is located outside the vacuum vessel, and the stainless steel plate 1 is located inside the vacuum vessel. The carbon steel plate 2 has a thickness of 15-20 mm, the stainless steel plate 1 has a thickness of 2-3 mm, the stainless steel plate 1 is 304 stainless steel, and the carbon steel plate 2 is Q345R carbon steel. A layer of film is set between the carbon steel plate 2 and the stainless steel plate 1, and the film is composed of BOPET film 6 and BOPP film 7, both of which have good tensile properties, heat resistance, and impact resistance, and BOPET film 6 has Good wear resistance, so the rest of the carbon steel plate 2 contacts. The BOPP film 7 is a biaxially oriented polypropylene film; the BOPET film 6 is a biaxially oriented polyester film, which is obtained by biaxially stretching and stretching PET resin af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com