Method for reducing hydrogen content in aluminum-lithium alloy casting

An aluminum-lithium alloy and hydrogen content technology, which is applied in the field of reducing hydrogen content in aluminum-lithium alloy casting, can solve the problems of large climate impact, no consideration of the problems of hydrogen removal and impurity purification of aluminum-lithium alloy, no transmission and impurity removal system design, etc. , to achieve the effect of controllable temperature and atmosphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

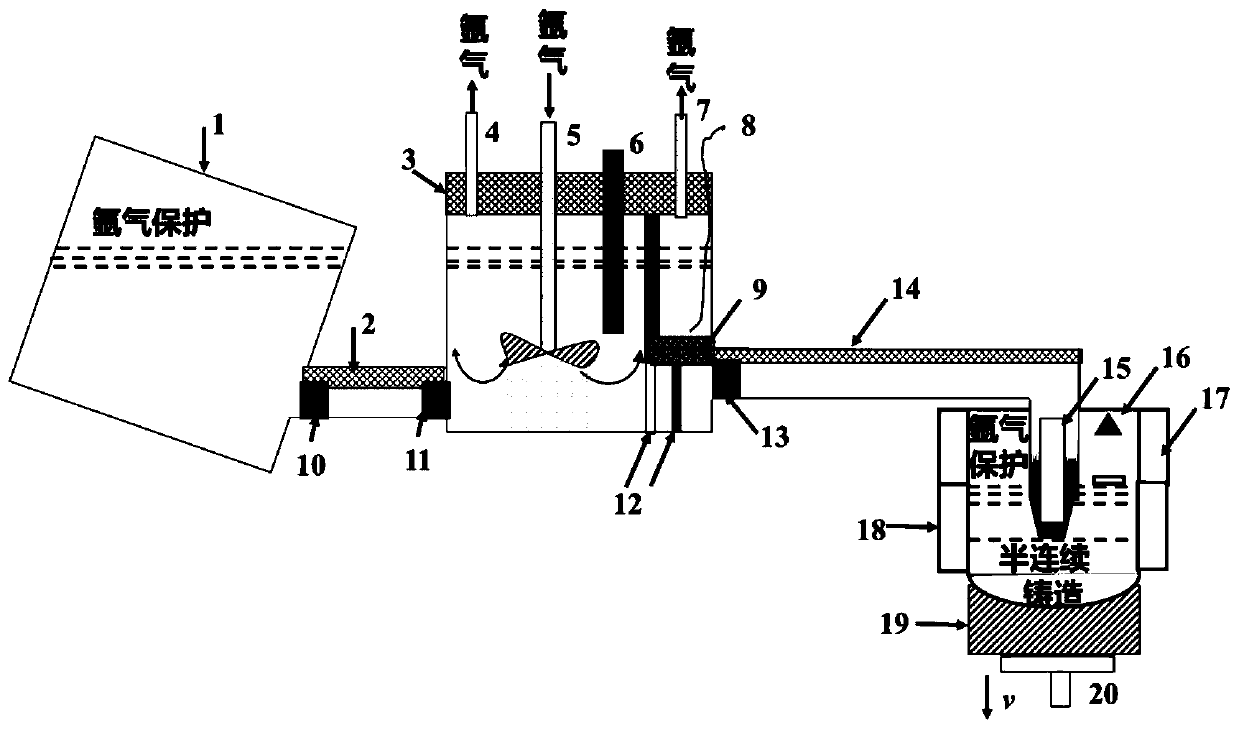

[0044] The purpose of the present invention is to provide a complete set of methods for protecting the aluminum-lithium alloy solution, reducing the hydrogen content and removing impurities, so as to effectively control the impurities and hole defects of the ingot and ensure the production of high-quality aluminum-lithium alloy ingot. The method includes:

[0045] 1. In the induction melting furnace, a certain amount of argon gas is injected from the top to form a melting environment isolated from the atmosphere, which effectively avoids the reaction of the aluminum-lithium alloy liquid surface absorbing hydrogen from the humid air;

[0046] 2. Between the smelting furnace and the dehydrogenation furnace such as the feed port, the aluminum-lithium alloy liquid transmission system adopts resistance heating, and is equipped with argon gas purging to ensure that the temperature and atmosphere are controllable during the transportation process;

[0047] 3. The dehydrogenation furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com