Preparation method of Ga2O3 and SnO2 mixed phase film with preferential orientations

A preferred orientation, mixed phase technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problem of difficult adjustment of single preferred orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The present invention provides a Ga with preferred orientation 2 o 3 and SnO 2 The preparation method of the miscible membrane is characterized in that: the preparation method is carried out according to the following steps:

[0017] (1) Ga 2 o 3 Powder, SnO 2 The powder and the carbon powder are mixed in a mass ratio of 1:0.01-2:1 and fully ground to obtain a solid mixed powder;

[0018] (2) Using the mixed powder as the reaction source, place the substrate and the reaction source in a high-temperature tube furnace, the temperature of the reaction source is 800°C-1200°C, and use the chemical vapor deposition method to reduce Ga by hot carbon 2 o 3 and SnO 2 Provide Ga source and Sn source, take oxygen as oxygen source, inert gas as carrier gas, flow ratio of oxygen and inert gas is 0.1-20mL / min: 0-100mL / min, substrate temperature is 800°C-1300°C, growth The pressure is 1 Pa-10 5 Pa, the deposition time is 5 min-60 min, and Ga with preferred orientation is obt...

Embodiment 1

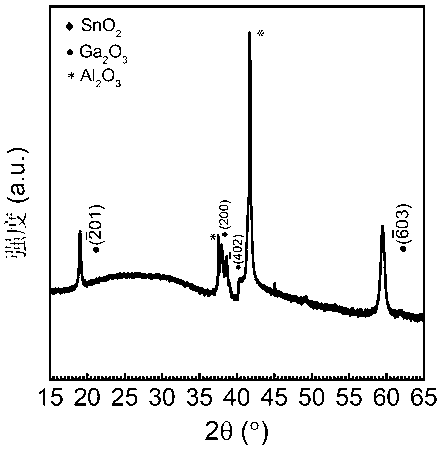

[0031] Ga 2 o 3 Powder, SnO 2 Powder and carbon powder are mixed in proportion and fully ground to obtain solid mixed powder, Ga 2 o 3 Powder, SnO 2 The mass ratio of powder to carbon powder mixed powder is 1:1:1; the mixed powder is placed in a ceramic boat as a reaction source, and the ceramic boat and c -Ga 2 o 3 The substrate was placed in a high-temperature tube furnace; the ratio of oxygen and argon was 7 mL / min: 30 mL / min. The temperature of the reaction source is 1130 °C, the temperature of the substrate is 1130 °C; the growth vacuum is 30 Pa; the deposition time is 30 min; the thickness of the miscible film is 450 nm, and the optical band gap is 5.1 eV; figure 1 ,exist c -Ga 2 o 3 Mixed-phase films grown on SnO 2 For (200) preferred orientation, β-Ga 2 o 3 It is (-201) preferred orientation, and all of them are single preferred orientation.

Embodiment 2

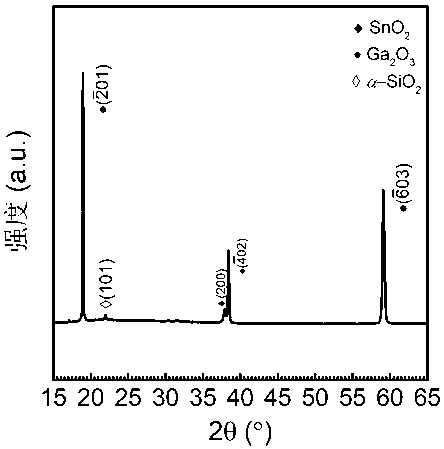

[0033] Ga 2 o 3 Powder, SnO 2 Powder and carbon powder are mixed in proportion and fully ground to obtain solid mixed powder, Ga 2 o 3 Powder, SnO 2 The mass ratio of powder to carbon powder mixed powder is 1:0.5:1; the mixed powder is placed in a ceramic boat as the reaction source, and the ceramic boat and quartz substrate are placed in a high-temperature tube furnace; the ratio of oxygen and argon is 7 mL / min: 30 mL / min; the reaction source temperature is 1050 °C, the substrate temperature is 1050 °C; the growth vacuum is 30 Pa; the substrate is treated at 1050 °C for 10 min before growth, and the deposition time is 30 min; the mixed-phase film thickness is 750 nm, the optical bandgap is 4.7 eV; figure 2 , quartz forms (101) α-SiO during heat treatment 2 ; In the grown miscible film, SnO 2 For (200) preferred orientation, β-Ga 2 o 3 It is (-201) preferred orientation, and all of them are single preferred orientation.

[0034] The above examples, by selecting and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com