Shock absorption skid-mounted comprehensive pipe gallery structure and construction method

A comprehensive pipe gallery and skid-mounted technology, which is used in infrastructure engineering, underwater structures, artificial islands, etc., can solve the problem that the pipe gallery structure cannot be cast and formed at one time, the lack of shock absorption measures and shock absorption structures, and the civil construction period. long and other problems, to achieve the effect of simple structure, reduced on-site workload, and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

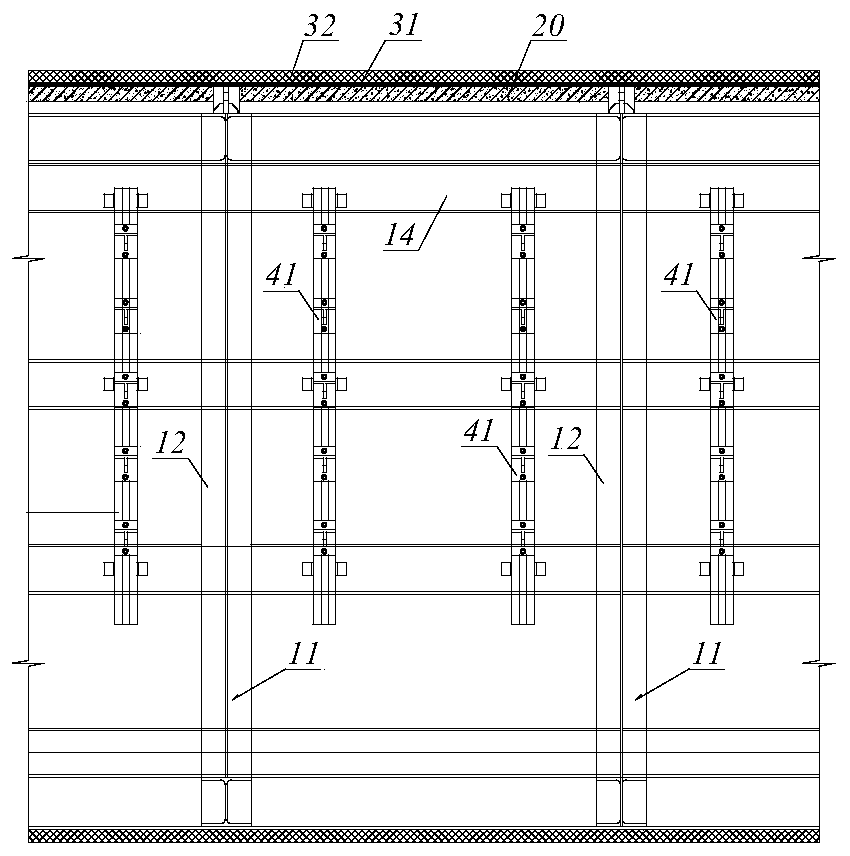

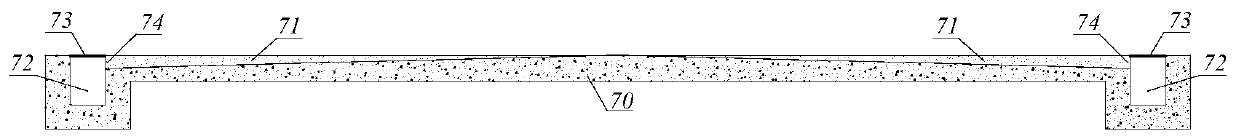

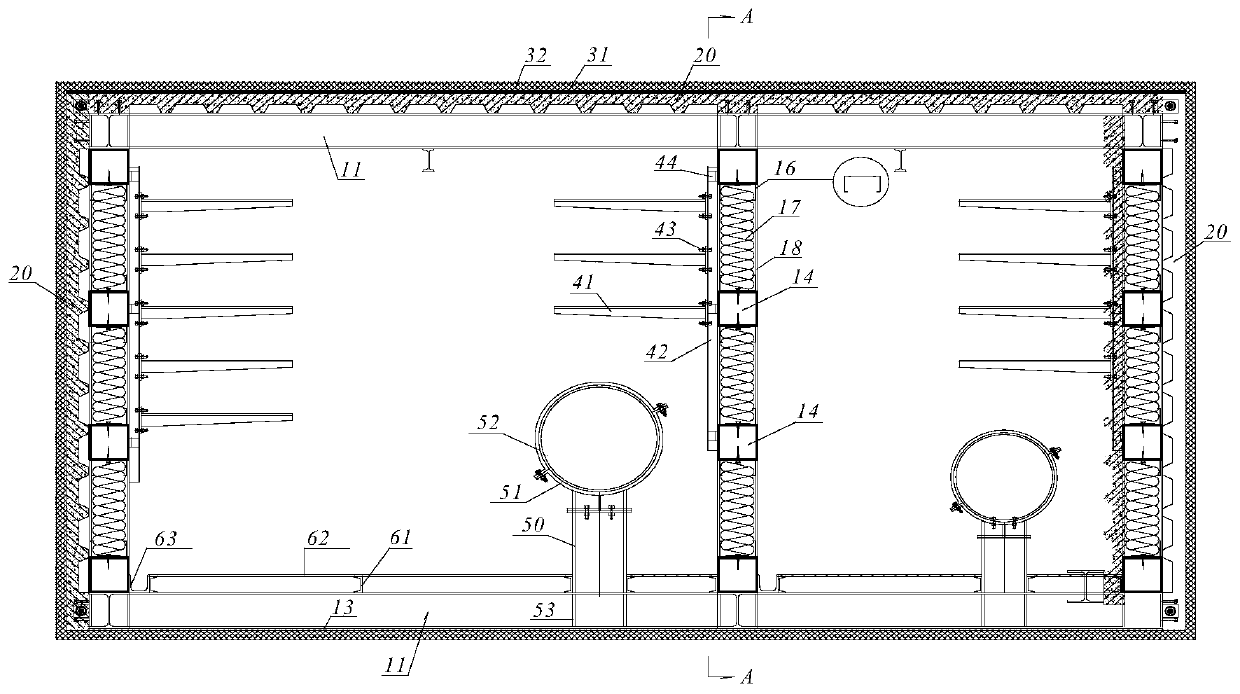

[0019] refer to figure 1 and figure 2 , a shock-absorbing skid-mounted comprehensive pipe gallery structure of the present invention includes a main structure of the pipe gallery and a shock-absorbing structure. The steel frame structure is welded by steel beams 11 and steel columns 12, the bottom of the steel frame structure is welded with a back-sealing steel plate 13, and the profiled steel plate concrete composite plate 20 is fixedly arranged on the top and two lateral sides of the steel frame structure. The combination of shaped steel plate and reinforced concrete bears the earth pressure together. Firewalls are set in the middle and two lateral sides of the steel frame structure, side wall support systems are set on the fire wall, and pipeline support structures and pedestrian passage structures are set at the bottom of the steel frame structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com