Pipeline dust cleaning robot

A technology of robot and dust cleaning mechanism, which is applied in the direction of special pipes, pipe components, mechanical equipment, etc., can solve the problems of explosion of combustibles, ineffective manual maintenance, and high risk of working environment, so as to achieve large transmission force, Improved operability and work efficiency, high stability and usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

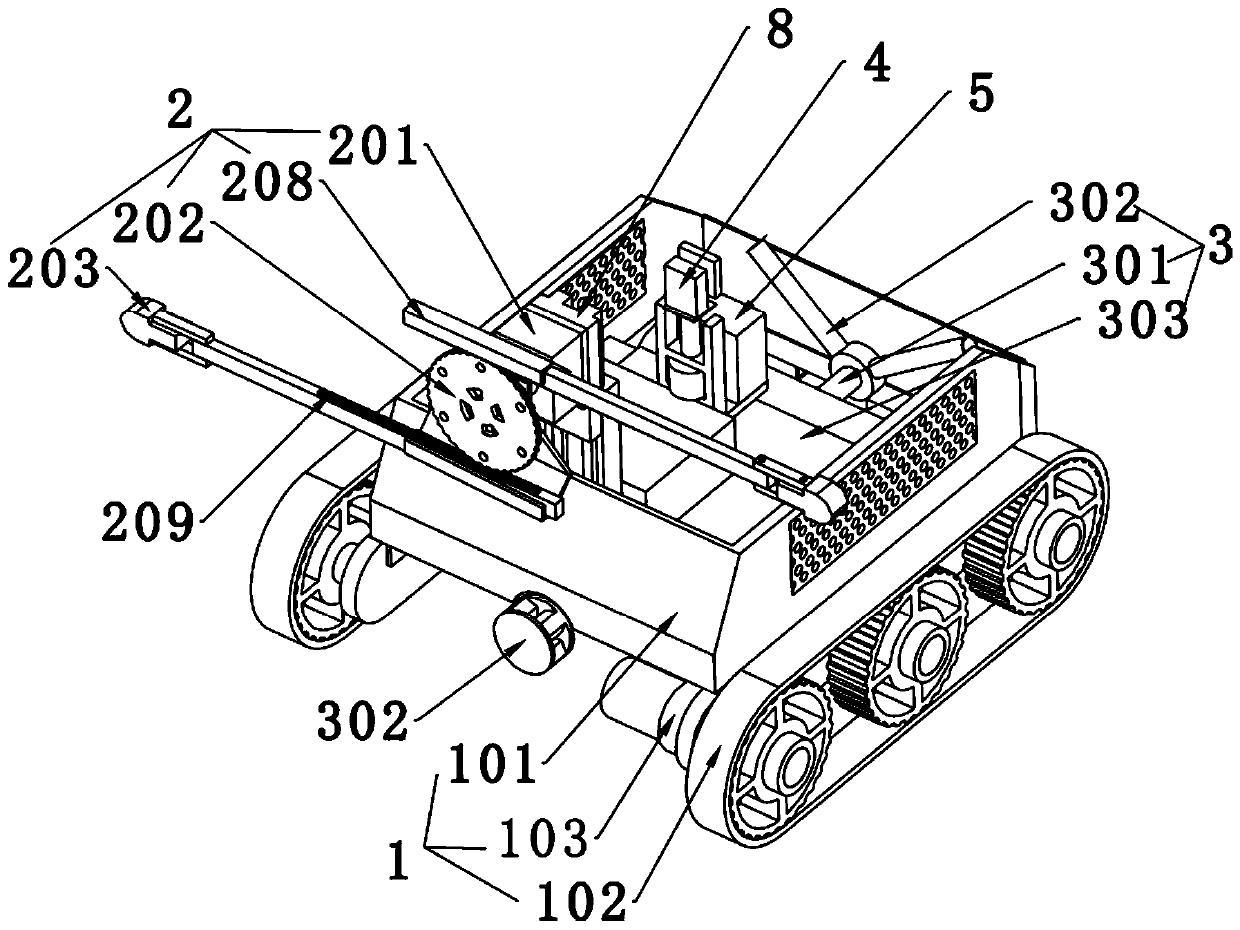

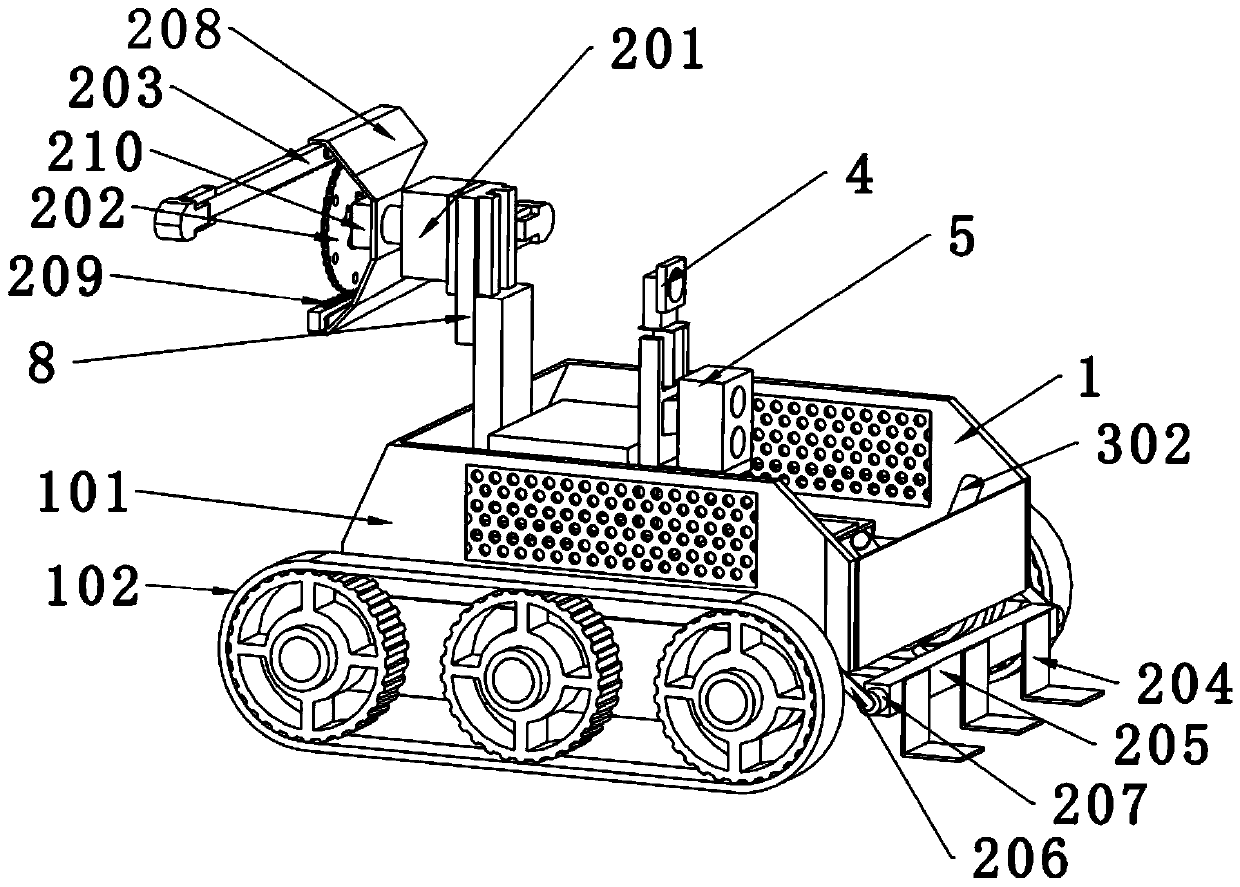

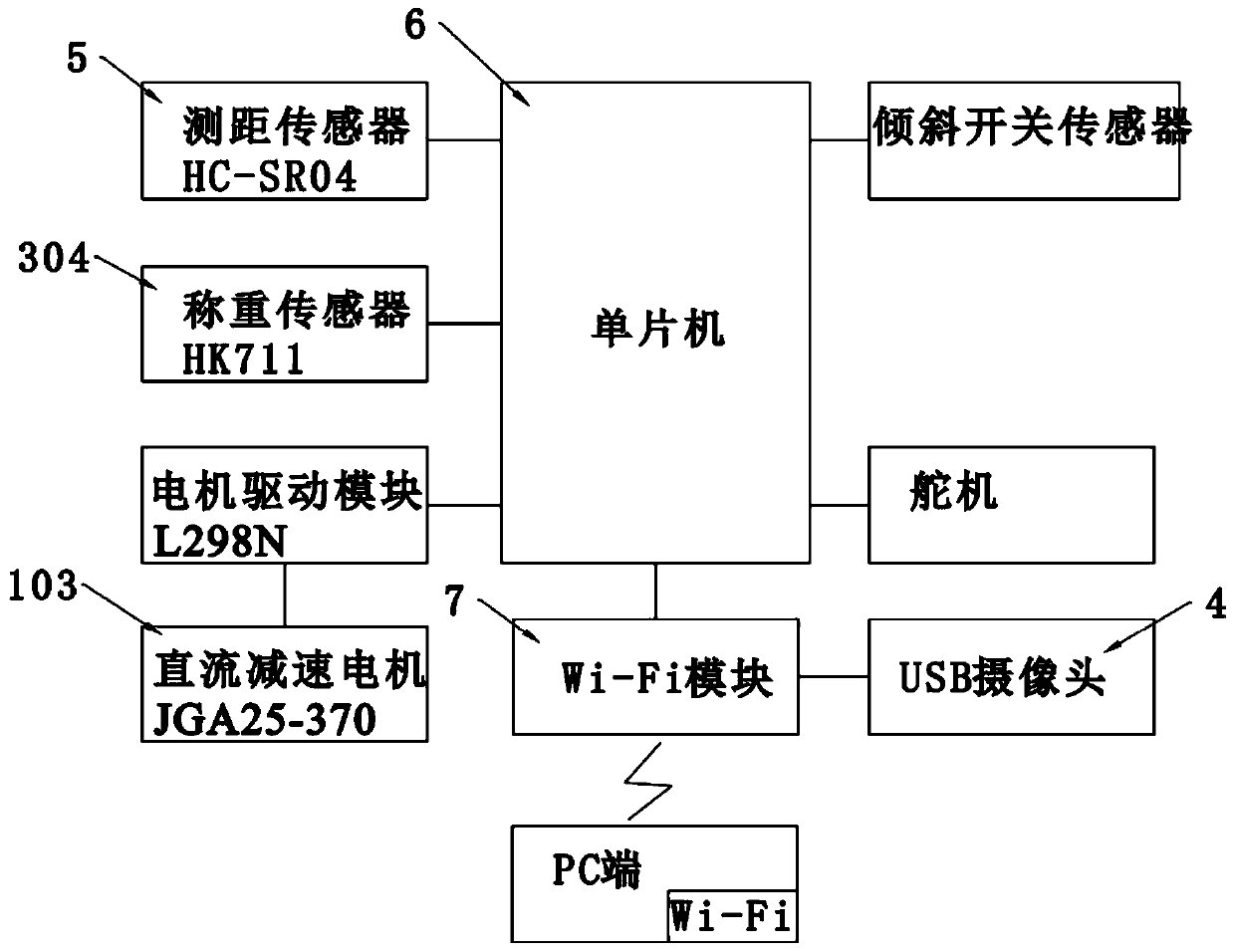

[0033] Such as Figure 1-Figure 4 As shown, a typical embodiment of the present application provides a pipeline dust cleaning robot, which includes a mobile carrier 11, a dust cleaning mechanism 2 for processing dust on the pipe wall, and a dust collection mechanism 32 for collecting dust 1. The detection mechanism and the control mechanism used to detect the inside of the pipeline, the dust cleaning mechanism 2, the dust collection mechanism 3 and the detection mechanism are all electrically connected to the control mechanism. The mobile carrier 1 includes a frame structure 101, crawler wheels 102, and a DC gear motor 103. The frame structure 101 is constructed of aluminum-shaped plates. Two sets of crawler wheels 102 are respectively arranged on both sides of the frame structure 101. One set of DC deceleration motors 103 is respectively connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com