Method for detecting safety of lithium ion battery diaphragm

A lithium-ion battery and detection method technology, which is applied in the direction of testing the strength of materials, measuring devices, and strength characteristics using one-time impact force, which can solve the problem of large differences in changing conditions, inability to reflect the thermal melting process of the diaphragm, and the inability to respond to the deformation process of the diaphragm, etc. problem, to achieve the effect of high consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The present embodiment provides a method for detecting the safety of a lithium ion battery diaphragm, comprising the following steps:

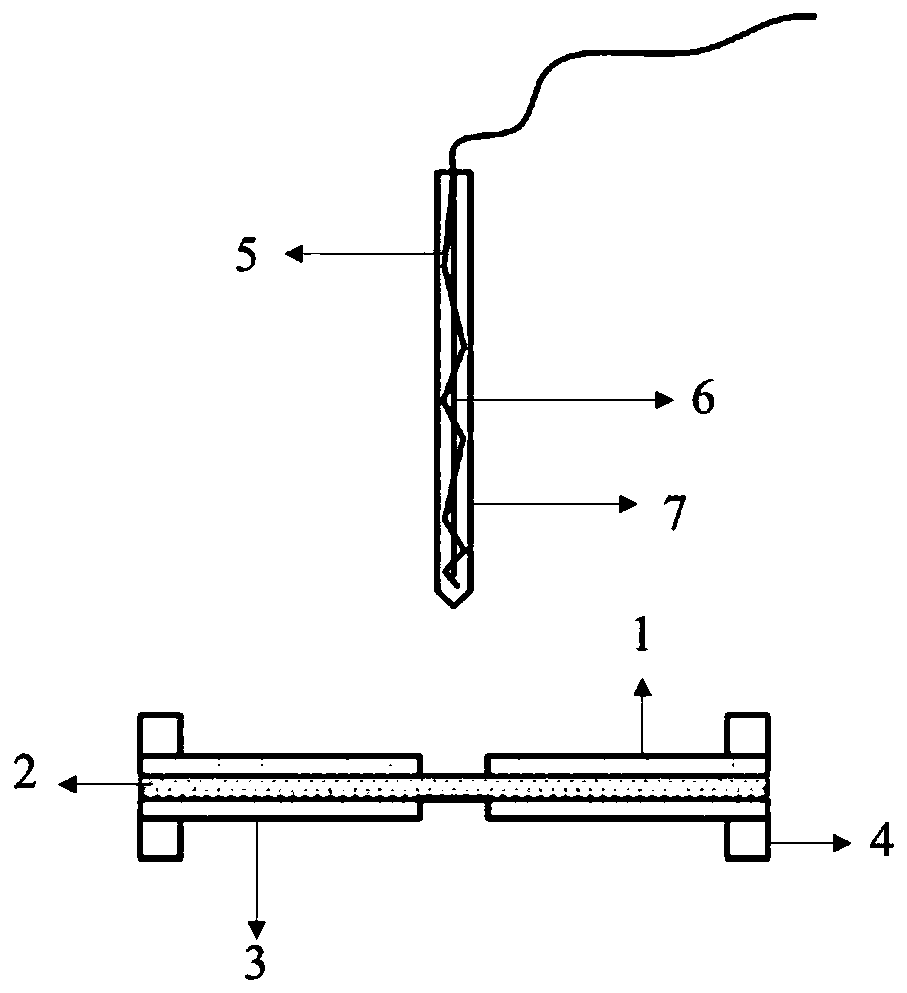

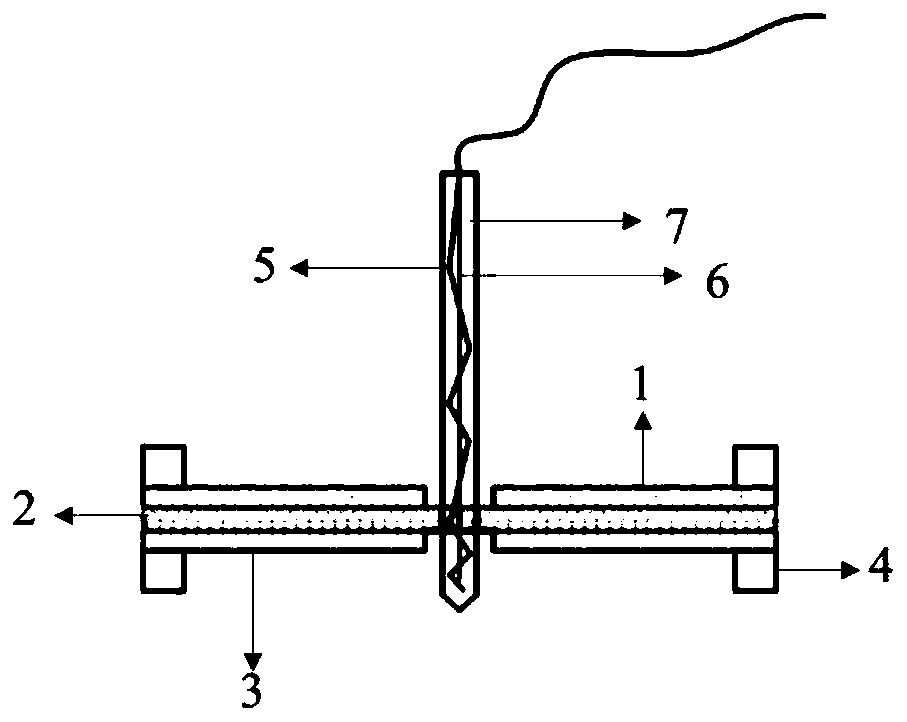

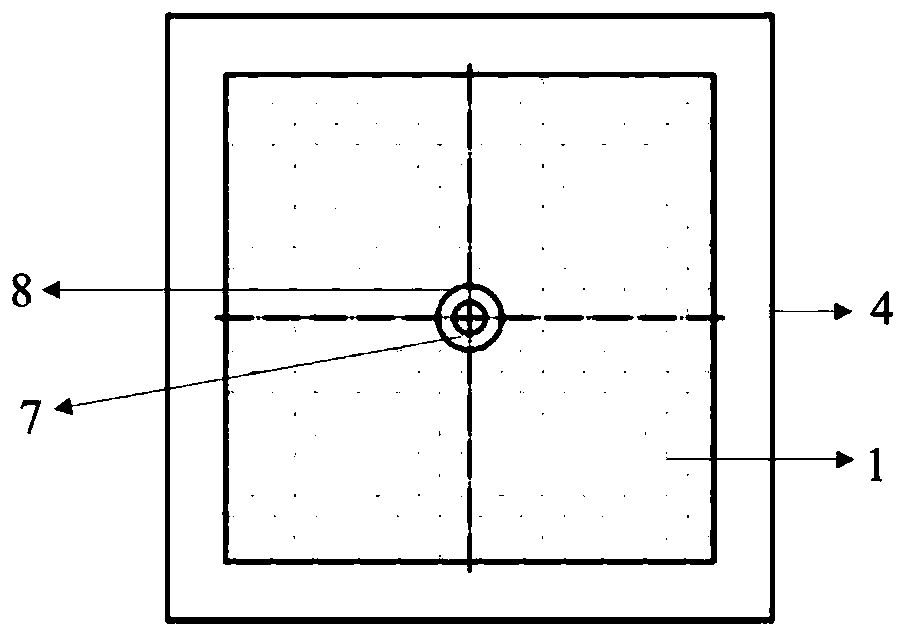

[0051] (1) take 3 each of A1, A2, A3, A4 separators, respectively fix the separator in the middle of the positive pole piece and the negative pole piece through the clamp; wherein, the center of the positive pole piece and the negative pole piece There are round holes, and the diameter of the round holes is 8mm;

[0052] (2) vertically penetrate the diaphragm from top to bottom at a rate of 6 mm / s and a constant temperature (60°C, 130°C, and 300°C, respectively), and keep it for a standing time of 10s; wherein, the The steel needle has a built-in heat resistance wire and a temperature probe, the cone angle of the needle tip of the steel needle is 45°-60°, and the diameter of the steel needle is 5 mm.

[0053] The present embodiment is directed to the influence of the type of diaphragm matrix; the test results are averaged, and the dama...

Embodiment 2

[0058] The present embodiment provides a method for detecting the safety of a lithium ion battery diaphragm, comprising the following steps:

[0059] (1) Take three A1 and B1 separators, respectively, fix the separators between the positive pole piece and the negative pole piece through a clamp; wherein, circles are left in the center of the positive pole piece and the negative pole piece hole, the diameter of the circular hole is 8mm;

[0060] (2) The steel needle vertically penetrates the diaphragm from top to bottom at a rate of 0.2 mm / s and a constant temperature (25° C. and 140° C., respectively), and maintains a standing time of 10 s; wherein, the steel needle The needle has a built-in heat resistance wire and a temperature probe, the cone angle of the needle tip of the steel needle is 45°-60°, and the diameter of the steel needle is 5 mm.

[0061] The present embodiment is directed to the influence of the thickness of the diaphragm base; the test results are averaged, ...

Embodiment 3

[0066] The present embodiment provides a method for detecting the safety of a lithium ion battery diaphragm, comprising the following steps:

[0067] (1) Take three A2 and B2 separators, respectively, and fix the separators in the middle of the positive pole piece and the negative pole piece through a clamp; wherein, the center of the positive pole piece and the negative pole piece is left with a circle hole, the diameter of the circular hole is 8mm;

[0068] (2) vertically penetrate the diaphragm from top to bottom at a rate of 30 mm / s and a constant temperature (40°C, 170°C, and 220°C, respectively), and keep it for a standing time of 10s; The steel needle has a built-in heat resistance wire and a temperature probe, the cone angle of the needle tip of the steel needle is 45°-60°, and the diameter of the steel needle is 5 mm.

[0069] This example is aimed at the influence of the thickness of the ceramic coating; the test results are averaged, and the damage of each diaphrag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com