Fiber integrated hydrogen sensor and manufacturing method thereof

A manufacturing method and sensor technology, applied in the field of optical fiber sensing, can solve the problems of fragile devices, high cost, unfavorable storage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

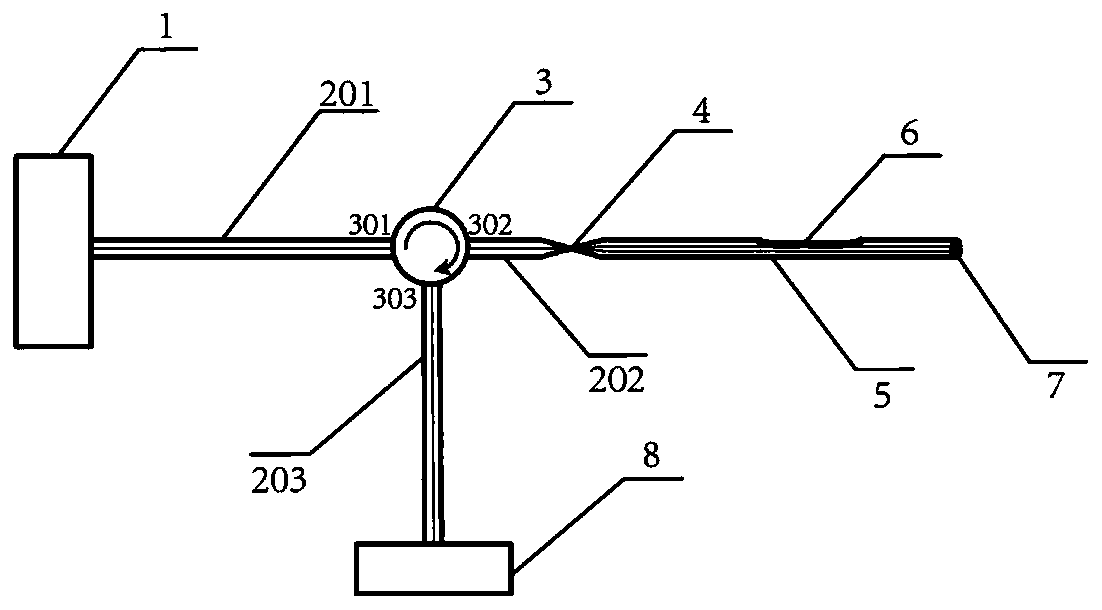

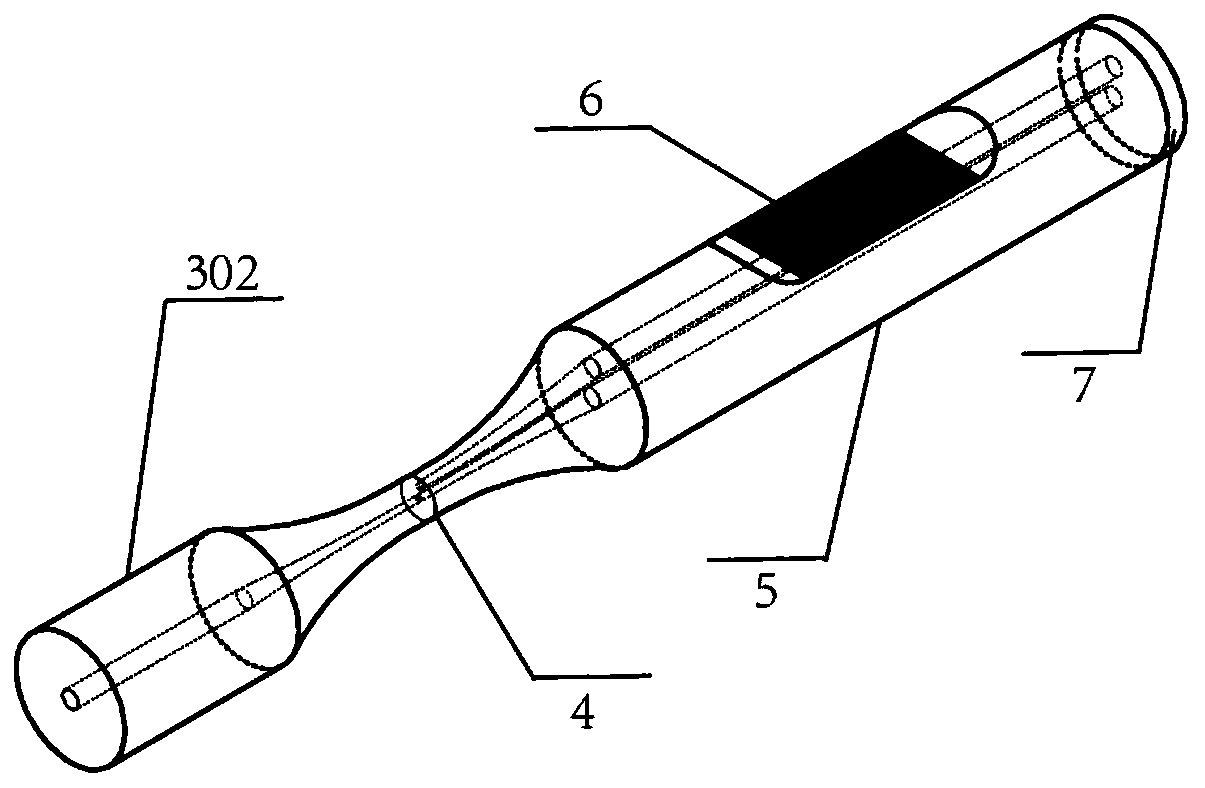

[0033] Such as figure 2 As shown, a fiber-integrated hydrogen sensor based on a symmetrical dual-core fiber.

[0034] Its device such as figure 1 As shown, it includes a light source 1 , a single-mode optical fiber 2 , an optical circulator 3 , a dual-core optical fiber 5 , a hydrogen sensitive film 6 , a reflective film 7 , and a spectrum analyzer 8 . The light emitted by the light source 1 is transmitted to the port 301 of the optical circulator through the single-mode optical fiber 201, and is output through the port 302. The light is coupled into the two cores of the D-type dual-core optical fiber 5 in a certain proportion through the optical fiber taper 4, and then passed through the end reflective film. 7 reflection, the light of the two fiber cores is transmitted back, and interferes through the fiber cone 4, the interference light is input from the optical circulator 302 port, and output through the 303 port, and the output light is monitored by the spectrum analyze...

Embodiment 2

[0038] A fiber-integrated hydrogen sensor based on a symmetrical dual-core optical fiber.

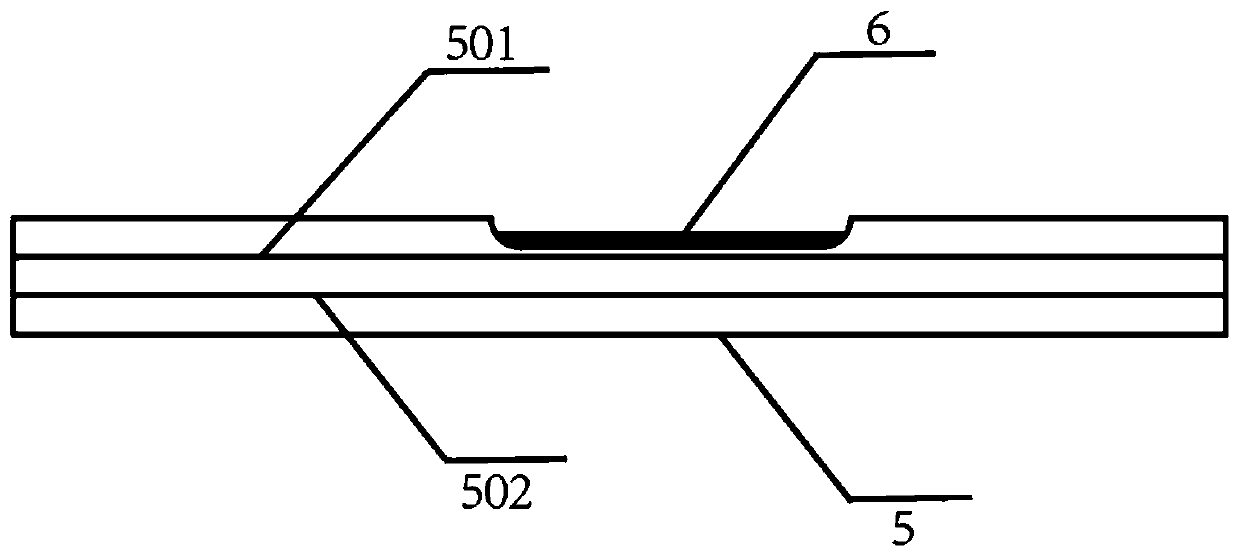

[0039] Its structure is the same as that of embodiment 1, the difference is that the double-core optical fiber used is an asymmetrical double-core optical fiber, and its structure diagram is as follows image 3 As shown, one of the cores is in the middle of the fiber and the other is in the outer cladding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com