Varnishing process of large-size copper-clad aluminum varnished wire

A copper-clad aluminum wire and copper-clad aluminum technology is applied in the direction of reducing the size of conductors/cables, insulating conductors/cables, electrical components, etc., to achieve the effects of saving production costs, stable performance and simple processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

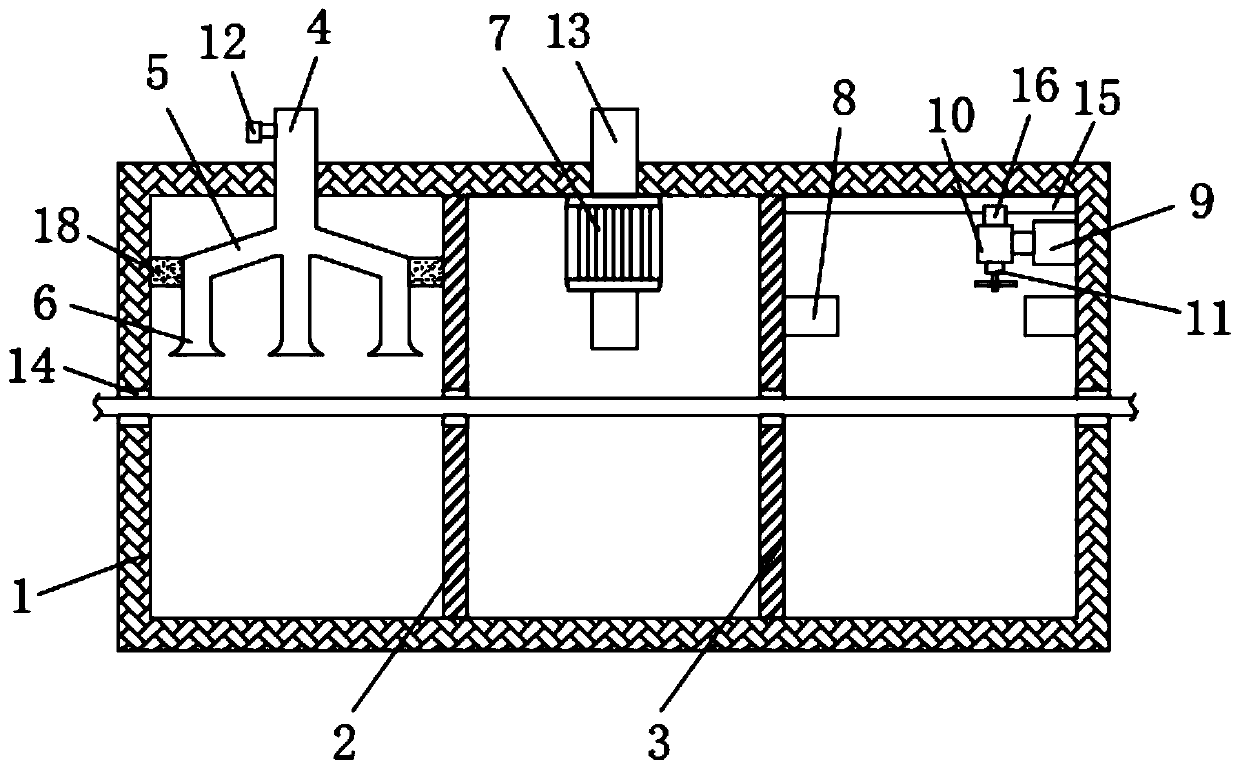

[0034] The invention provides a painting process for large-scale copper-clad aluminum enameled wire, which comprises the following steps:

[0035] Step A: making a copper-clad aluminum wire core: preparing a copper-clad aluminum wire core with a copper content of 0.3 wt %;

[0036] Step B: drawing: the copper-clad aluminum wire core is drawn multiple times to obtain a wire with a predetermined diameter;

[0037] Step C: annealing: first, the copper-clad aluminum wire obtained in step B is cleaned with pure water at 50°C, and then introduced into an annealing furnace for annealing treatment;

[0038] Step D: cooling: cooling the annealed copper-clad aluminum wire core through a cooling device in step C;

[0039] Step E: painting: introduce the copper-clad aluminum wire into the paint area of the oven at a speed of 500m / min, and apply imine-modified polyimide insulating varnish on the copper-clad aluminum wire through felt or mold;

[0040] Step F: Take-up: After the copper-...

Embodiment 2

[0042] The invention provides a painting process for large-scale copper-clad aluminum enameled wire, which comprises the following steps:

[0043] Step A: making a copper-clad aluminum wire core: preparing a copper-clad aluminum wire core with a copper content of 0.4wt%;

[0044] Step B: drawing: the copper-clad aluminum wire core is drawn multiple times to obtain a wire with a predetermined diameter;

[0045] Step C: annealing: first, the copper-clad aluminum wire obtained in step B is cleaned with pure water at 60°C, and then introduced into an annealing furnace for annealing treatment;

[0046] Step D: cooling: cooling the annealed copper-clad aluminum wire core through a cooling device in step C;

[0047] Step E: painting: introduce the copper-clad aluminum wire into the paint area of the oven at a speed of 600m / min, and apply imine-modified polyimide insulating varnish on the copper-clad aluminum wire through a felt or mold;

[0048] Step F: Take-up: After the copper-...

Embodiment 3

[0050] The invention provides a painting process for large-scale copper-clad aluminum enameled wire, which comprises the following steps:

[0051] Step A: making a copper-clad aluminum wire core: preparing a copper-clad aluminum wire core with a copper content of 0.5 wt %;

[0052] Step B: drawing: the copper-clad aluminum wire core is drawn multiple times to obtain a wire with a predetermined diameter;

[0053] Step C: annealing: first clean the copper-clad aluminum wire obtained in step B with pure water at 70°C, and then introduce it into an annealing furnace for annealing treatment;

[0054] Step D: cooling: cooling the annealed copper-clad aluminum wire core through a cooling device in step C;

[0055]Step E: painting: introduce the copper-clad aluminum wire into the paint area of the oven at a speed of 5700m / min, and apply imide-modified polyimide insulating varnish on the copper-clad aluminum wire through a felt or a mold;

[0056] Step F: Take-up: After the copper-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com