Preparation method of solar power generation unit and prepared solar power generation unit

A power generation unit, solar energy technology, applied in photovoltaic power generation, electrical components, circuits, etc., can solve the problems of single fabric layer shape, unable to meet diversified use needs, etc., to achieve the effect of improving aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

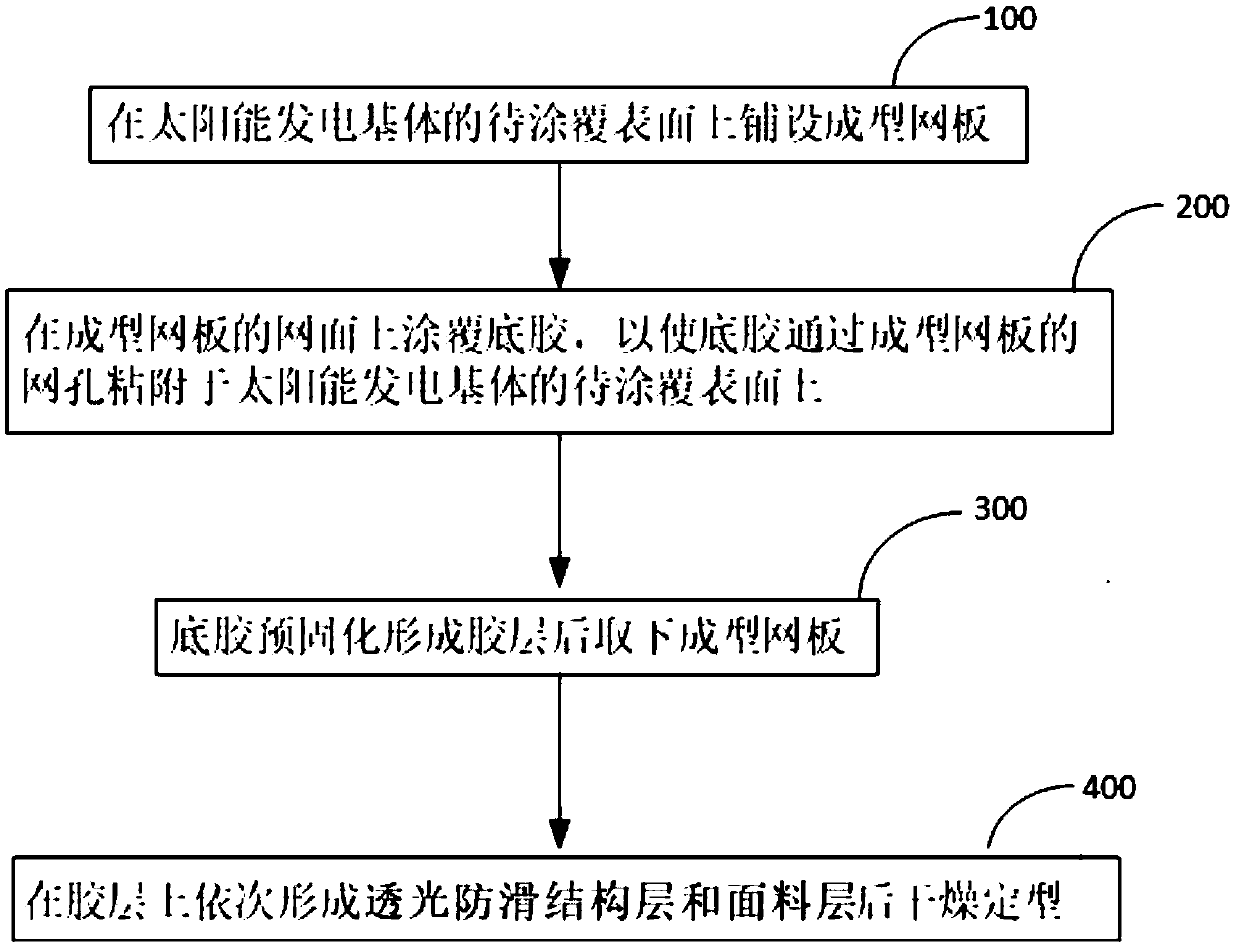

[0042] Such as figure 1 As shown, the embodiment of the present invention provides a method for preparing a solar power generation unit, including:

[0043] Step 100, laying a forming mesh on the surface to be coated of the solar power generation substrate;

[0044] Step 200, coating the primer on the mesh surface of the forming screen, so that the primer adheres to the surface to be coated of the solar power generation substrate through the mesh of the forming screen;

[0045] Step 300, the primer is pre-cured to form the glue layer 12, and then the forming screen is removed;

[0046] Step 400, sequentially forming a light-transmitting anti-slip structure layer and a fabric layer 14 on the adhesive layer 12, and then drying and shaping.

[0047] The preparation method of the above-mentioned solar power generation unit is based on the surface of the solar power generation substrate facing the light side, and the above-mentioned adhesive layer 12, the light-transmitting anti-...

Embodiment 1

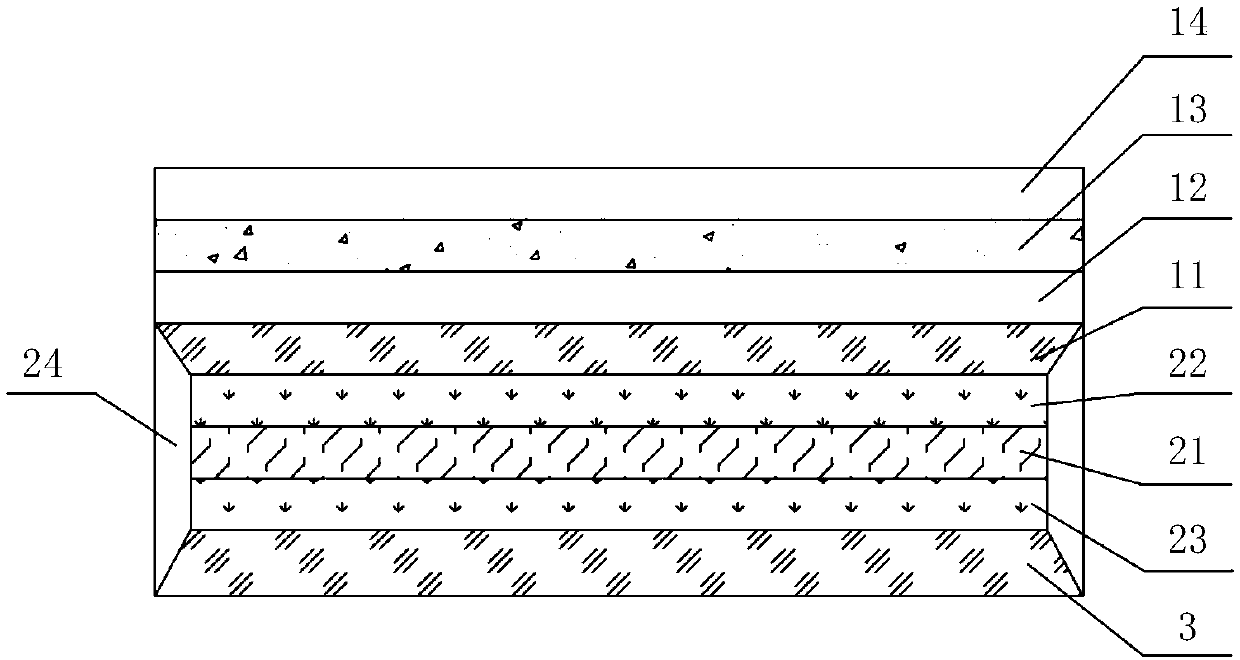

[0076] In the solar power generation substrate, the light-transmitting glass layer 11 is made of ultra-clear float glass with a thickness of 6 mm; the back glass layer 3 is made of tempered glass with a thickness of 4 mm; The conversion layer 21 is a copper indium gallium selenium thin film solar cell layer, and the second adhesive layer 23 is an ethylene-vinyl acetate copolymer film layer. The back glass layer, the first adhesive layer 22, the photoelectric conversion layer 21, the second adhesive layer 23 and the light-transmitting glass layer are sequentially stacked and laminated, so that the light-transmitting glass layer 11 and the back glass layer 3 The edges protrude from the edges of the photoelectric conversion layer 21, the first adhesive layer 22 and the second adhesive layer 23 (the photoelectric conversion layer 21, the first adhesive layer 22 and the second adhesive layer 23 overlap), forming a receiving groove, Wherein, the stacked photoelectric conversion laye...

Embodiment 2

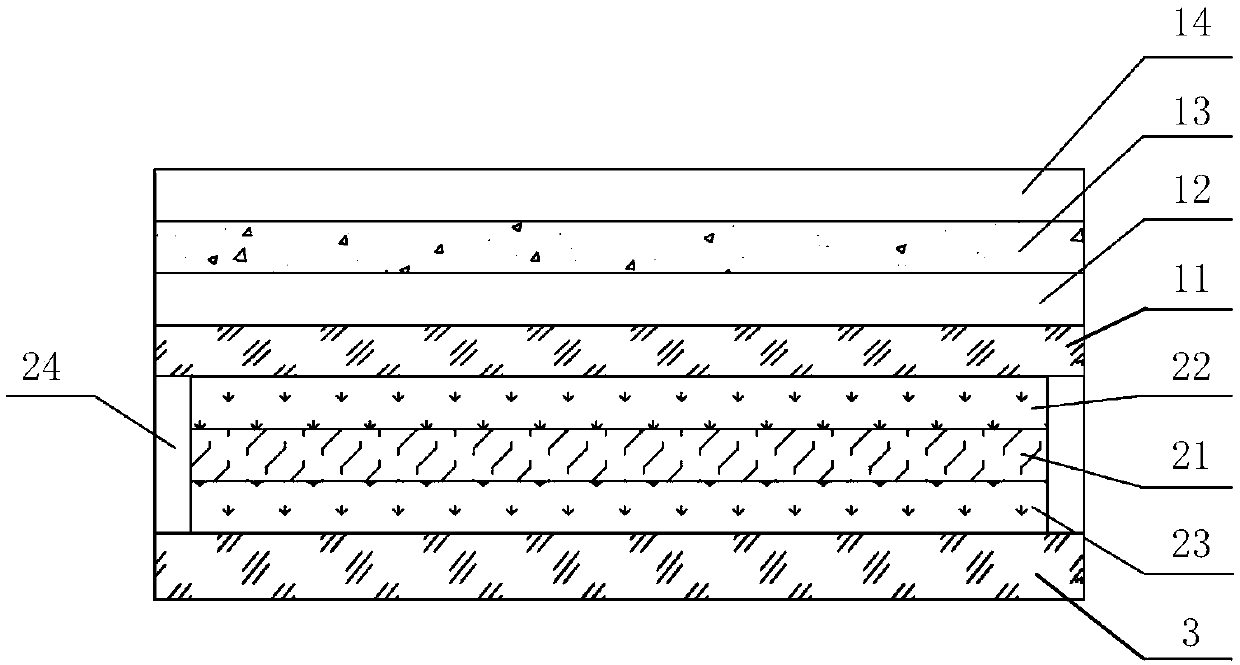

[0082] In the solar power generation substrate, the light-transmitting glass layer 11 is made of ultra-clear float glass with a thickness of 6 mm; the back glass layer is made of toughened glass with a thickness of 4 mm; Layer 21 is made of copper indium gallium selenide thin film solar cell layer, and the second adhesive layer 23 is made of ethylene-octene copolymer film layer. The back glass layer 3, the first adhesive layer 22, the photoelectric conversion layer 21, the second adhesive layer 23, and the light-transmitting glass layer are sequentially stacked and laminated, so that the light-transmitting glass layer 11 and the back glass layer 3 The edge protrudes from the edge of the photoelectric conversion layer 21, the first adhesive layer 22 and the second adhesive layer 23 (the photoelectric conversion layer 21, the first adhesive layer 22 and the second adhesive layer 23 overlap), forming a receiving groove , wherein the laminated photoelectric conversion layer 21, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com