Ultraviolet light catalyzed electrospinning anti-haze window screen and preparation method thereof

An electrospinning and anti-haze technology is applied in the field of ultraviolet photocatalytic electrospinning anti-haze window screens and their preparation, which can solve problems such as hindering and protecting effects, and achieve the effects of enhancing strength, eliminating air pollution and thinning thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] TiO with a molecular sieve-like structure used in the embodiments of the present invention 2 The preparation method of powder comprises the following steps:

[0034] a) Template compounding agent solution: take 300mL industrial TiOSO 4 The solution was heated to 100°C and stirred for 15 minutes to obtain hot titanium solution; take quantitative cetyltrimethylammonium bromide (CTAB), polyethylene oxide-polypropylene oxide-polyethylene oxide tertiary (P- 123) and sodium silicate (Na 2 SiO 3 9H 2 O) be dissolved in 600mL water, and raw material molar ratio is: X (Ti): X (CTAB): X (P-123): X (Si)=1: 0.2: 0.02: 0.02; Measure triethylamine ( TEA) 15mL, and n-pentanol 15mL were added thereto, stirred and mixed evenly, configured as a template compounding agent solution, and placed in a constant temperature oil bath at 70°C and stirred for 15 minutes;

[0035] b) Take 200ml of the composite template solution prepared in step a) and place it in a three-necked bottle in a co...

Embodiment 1

[0040] A method for preparing an ultraviolet photocatalyzed electrospinning anti-fog and haze window screen, comprising the following steps:

[0041] (1) Configure the precursor spinning solution: TiO with a molecular sieve-like structure 2 The powder was added to DMF and treated with an ultrasonic crusher for 2 hours to make TiO with a molecular sieve-like structure 2 Uniformly dispersed in solvent to make 0.5wt% TiO 2 Dispersion solution, stirring at room temperature to TiO 2 Add PMMA to the dispersion, stir for 8 hours until the mixed solution is uniform and clear; then add PEO to the solution and stir for 8 hours, then add ECA to the solution, and continue stirring for 12 hours to obtain a homogeneous and transparent precursor spinning solution with suitable viscosity. The content of PMMA in the silk liquid is 15wt%, the content of PEO is 0.8wt%, and the content of ECA is 2.0wt%;

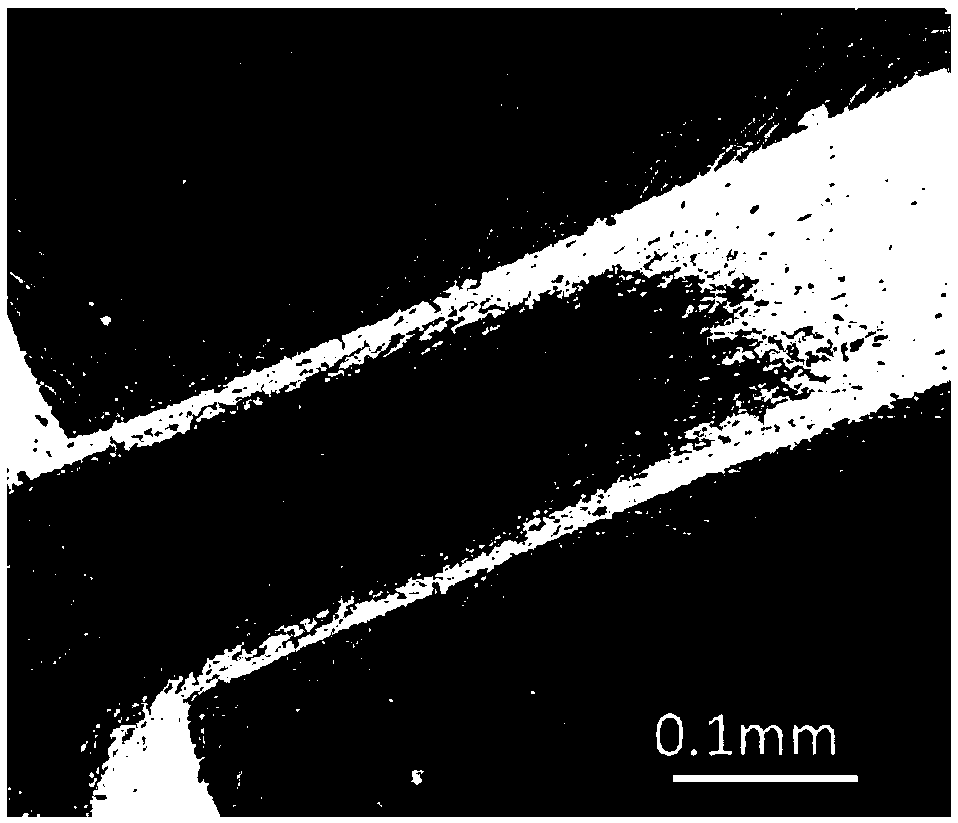

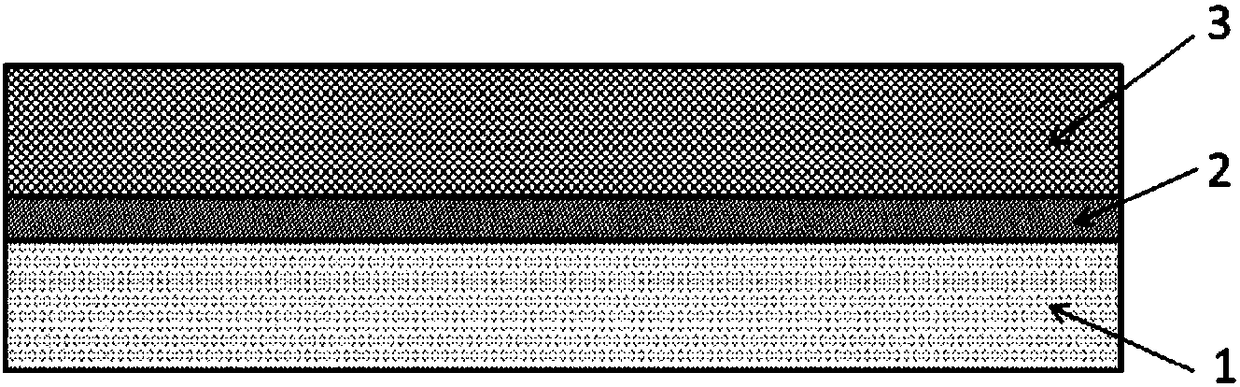

[0042] (2) Pretreatment base layer: the base layer is a copper screen (metal screen) with...

Embodiment 2

[0048] A method for preparing an ultraviolet photocatalyzed electrospinning anti-fog and haze window screen, comprising the following steps:

[0049] (1) Configure the precursor spinning solution: TiO with a molecular sieve-like structure 2 The powder was added to DMF, and treated with an ultrasonic crusher for 3 hours to make TiO with a molecular sieve-like structure 2 Uniformly dispersed in solvent to make 1wt% TiO 2 Dispersion solution, stirring at room temperature to TiO 2 Add PMMA to the dispersion, stir for 8 hours until the mixed solution is uniform and clear; then add PEO to the solution and stir for 8 hours, then add ECA to the solution, and continue stirring for 12 hours to obtain a homogeneous and transparent precursor spinning solution with suitable viscosity. The content of PMMA in the silk liquid is 20wt%, the content of PEO is 0.6wt%, and the content of ECA is 1.5wt%;

[0050] (2) Pretreatment base layer: the base layer is a stainless steel screen (metal scre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com