A centering strut and a loudspeaker with the same

A technology of centering struts and loudspeakers, applied in the field of electroacoustics, to achieve the effects of simple production process, low production cost and enhanced protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

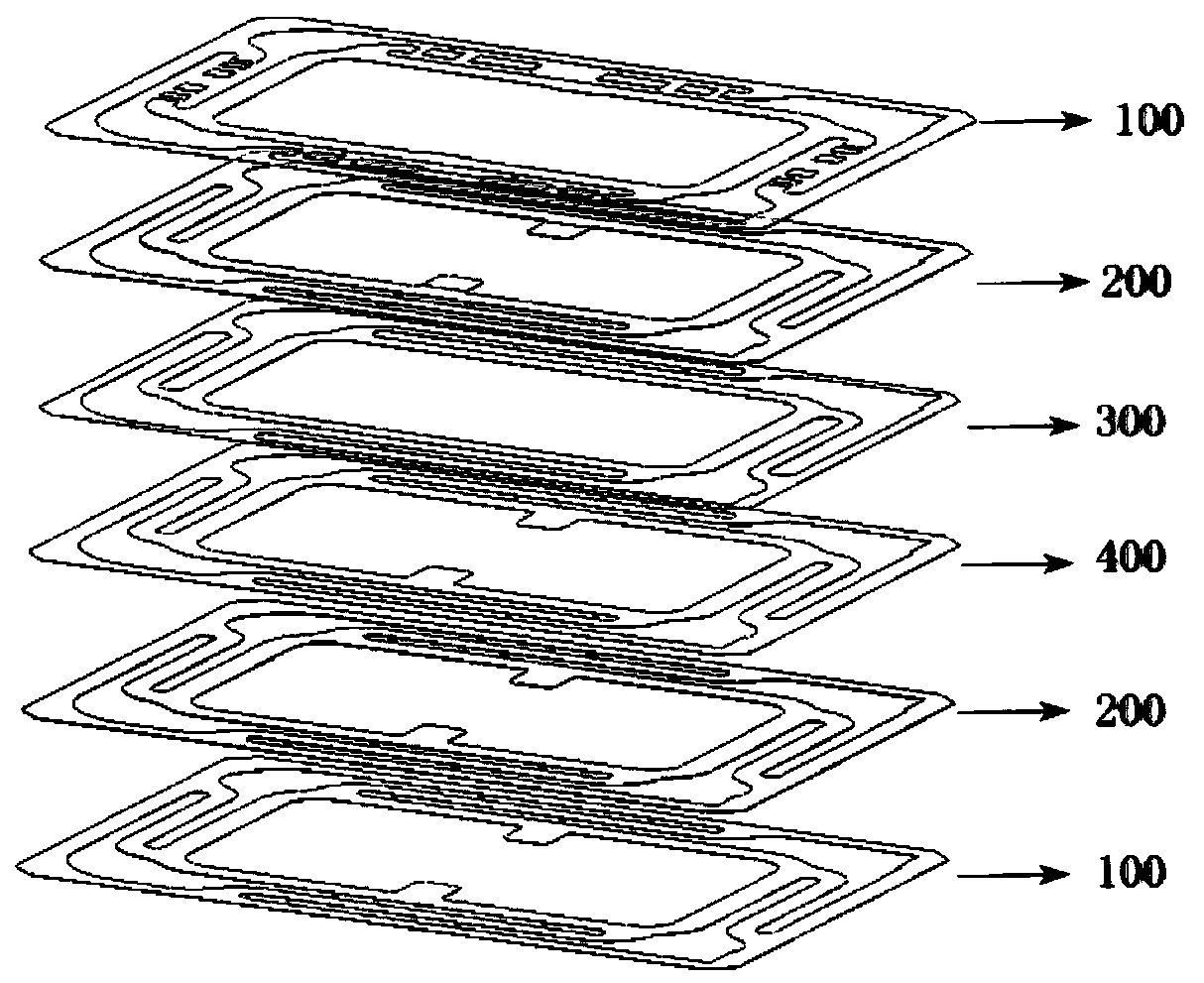

[0042] A centering strut, which adopts a multi-layer structure composed of multiple material layers or a multi-layer structure composed of multiple material layers and glue layers. The material layer includes a conductive layer located in the central area and a conductive layer located on the outer surface. Substrate layer, the substrate layer can be polyimide (PI) film, the conductive layer can be copper foil, the copper foil is adhered to the polyimide film coated with adhesive by rolling process, or no The adhesive produces copper foil directly on the polyimide film.

[0043]The substrate layer is not limited to the above-mentioned polyimide film, and other polymer material films other than polyimide can also be selected, and the conductive layer is not limited to the above-mentioned copper foil, and can also be other metals. layer or graphene conductive layer, etc.

[0044] Taking the described damper as an example of a six-layer layered structure for illustration, in thi...

Embodiment 2

[0071] The same part as that of Embodiment 1 has been discussed in detail in Embodiment 1, and will not be repeated here. Compared with Embodiment 1, this embodiment is modified as follows:

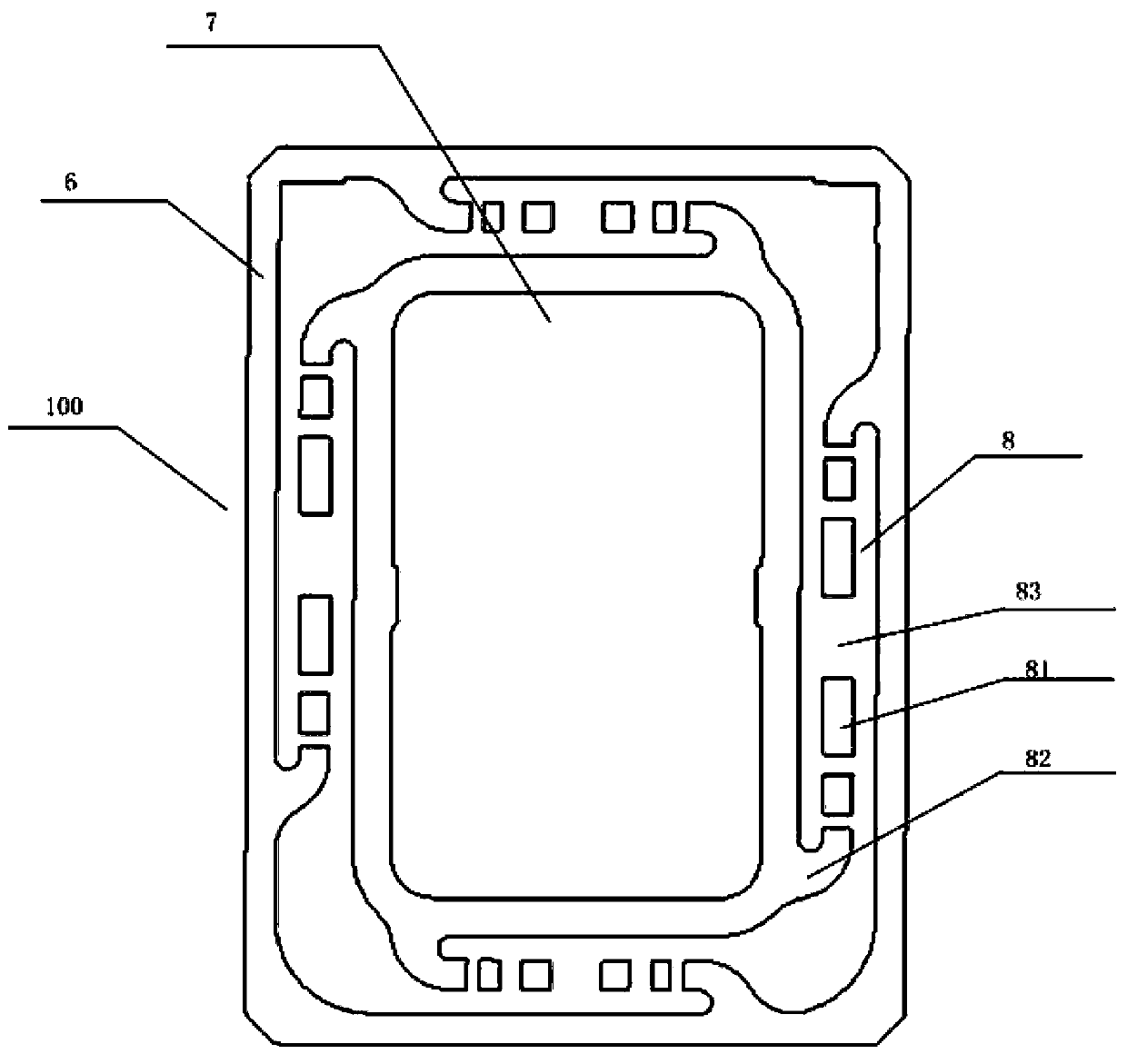

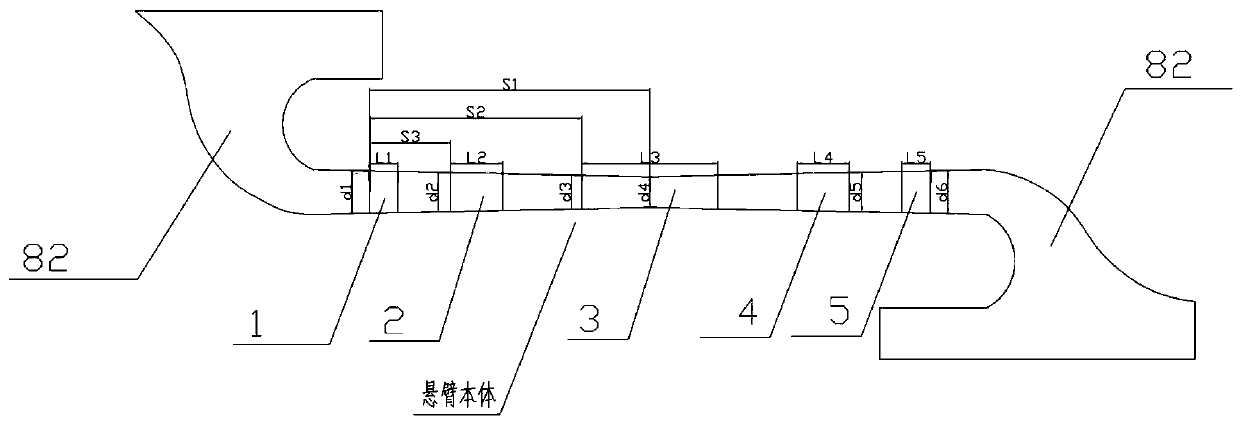

[0072] preferred, such as image 3 As shown, the first cantilever unit 1 , the second cantilever unit 2 , the third cantilever unit 3 , the fourth cantilever unit 4 and the fifth cantilever unit 5 are distributed symmetrically with respect to the center line of the cantilever body 8 .

[0073] The shape of the first cantilever unit 1, the second cantilever unit 2, the fourth cantilever unit 4 and the fifth cantilever unit 5 is trapezoidal, and the shape of the third cantilever unit 3 is symmetrical to the center line of the cantilever body 8. Narrow shape in the middle.

[0074] The length L1 of the first cantilever unit 1 is the same as the length L5 of the fifth cantilever unit 5, the length L2 of the second cantilever unit 2 is the same as the length L4 of the fourth cantilever unit 4...

Embodiment 3

[0086] The same part as that of Embodiment 1 has been discussed in detail in Embodiment 1, and will not be repeated here. Compared with Embodiment 1, this embodiment is modified as follows:

[0087] preferred, such as Figure 4 As shown, the first cantilever unit 1 , the second cantilever unit 2 , the third cantilever unit 3 , the fourth cantilever unit 4 and the fifth cantilever unit 5 are asymmetrically distributed with respect to the center line of the cantilever body.

[0088] The shape of the first cantilever unit 1, the second cantilever unit 2, the fourth cantilever unit 4 and the fifth cantilever unit 5 is trapezoidal, and the shape of the third cantilever unit 3 is symmetrical to the center line of the cantilever body 8. Narrow shape in the middle.

[0089] The length L1 of the first cantilever unit 1 is the same as the length L5 of the fifth cantilever unit 5, the length L2 of the second cantilever unit 2 is the same as the length L4 of the fourth cantilever unit 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com