Preparation method of micro-emulsified essence

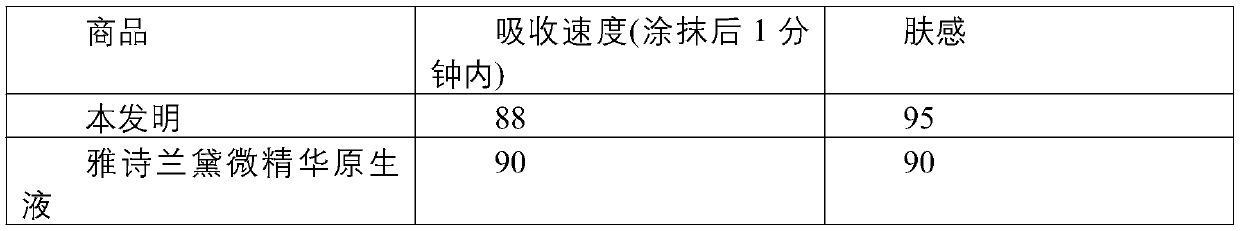

A technology of micro-emulsion and essence, applied in the field of skin care products, can solve the problems of inability to effectively promote the absorption of essence, reduce the effect of essence, and poor moisturizing effect of essence, so as to reduce pigmentation and dullness. The effect of stacking, easy handling, and easy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

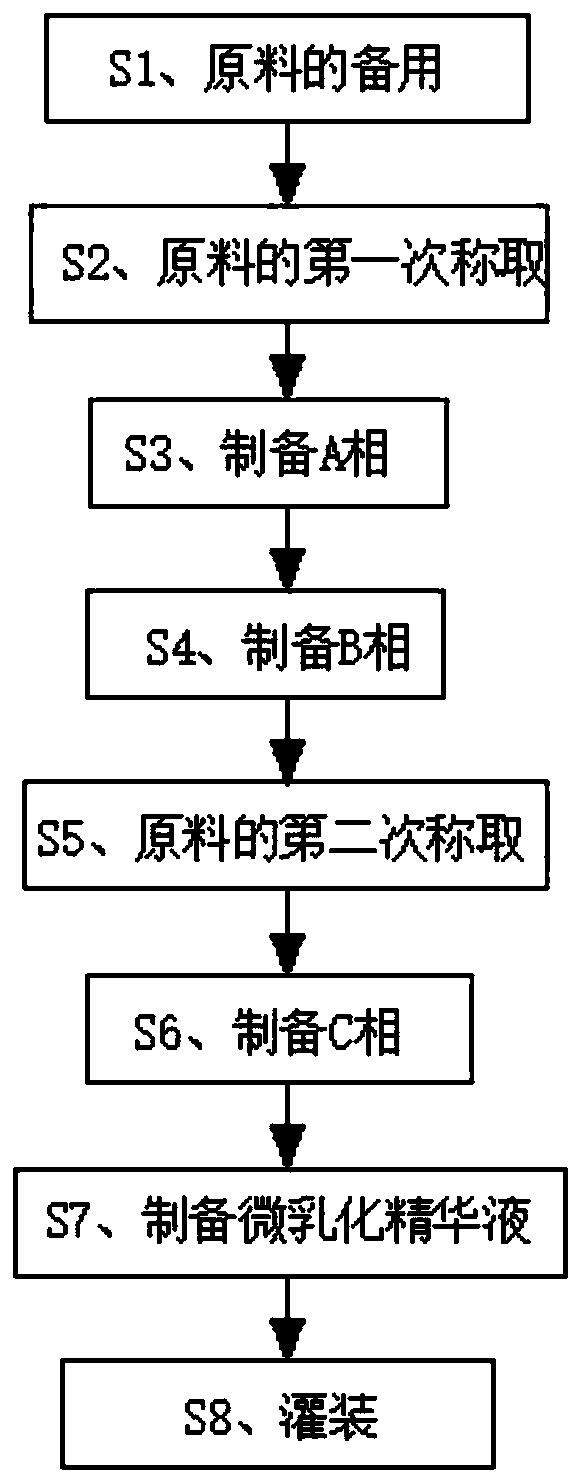

[0027] Example 1: Please refer to figure 1 , the invention discloses a preparation method of microemulsion essence, comprising the following steps:

[0028] S1. Spare raw materials: PPG-5-Ceteth-202.67%, Oleth-3 Phosphate 1.33%, White Pond Seed Oil 1%, 10% NaOH 0.93%, 1,3 Propylene Glycol 5% , oat beta-glucan 3%, [phenoxyethanol, ethylhexylglycerin] 0.8%, water 85.27%, microemulsion matrix 3% and plant extract 6%;

[0029] S2. The first weighing of raw materials: take a beaker, weigh the required PPG-5-cethyl polyether-20, oleth-3 phosphate and white pond flower seed oil in proportion and put them into the beaker In the process, the required raw materials are obtained and set aside;

[0030] S3, prepare phase A: heat the raw materials in the beaker in step S1 while mixing, after mixing evenly, obtain the required phase A, keep it warm for subsequent use;

[0031] S4, preparation of phase B: measure the required water and put it into a beaker, heat it, slowly add the heated ...

Embodiment 2

[0040] Example 2: Please refer to figure 1 , the invention discloses a preparation method of microemulsion essence, comprising the following steps:

[0041] S1. Spare raw materials: PPG-5-Ceteth-202.67%, Oleth-3 Phosphate 1.33%, White Pond Seed Oil 1%, 10% NaOH 0.93%, 1,3 Propylene Glycol 5% , oat beta-glucan 3%, [phenoxyethanol, ethylhexylglycerin] 0.8%, water 85.27%, microemulsion matrix 3% and plant extract 6%;

[0042] S2. The first weighing of raw materials: take a beaker, weigh the required PPG-5-cethyl polyether-20, oleth-3 phosphate and white pond flower seed oil in proportion and put them into the beaker In the process, the required raw materials are obtained and set aside;

[0043] S3, prepare phase A: heat the raw materials in the beaker in step S1 while mixing, after mixing evenly, obtain the required phase A, keep it warm for subsequent use;

[0044] S4, preparation of phase B: measure the required water and put it into a beaker, heat it, slowly add the heated ...

Embodiment 3

[0053] Example 3: Please refer to figure 1 , the invention discloses a preparation method of microemulsion essence, comprising the following steps:

[0054] S1. Spare raw materials: PPG-5-Ceteth-202.67%, Oleth-3 Phosphate 1.33%, White Pond Seed Oil 1%, 10% NaOH 0.93%, 1,3 Propylene Glycol 5% , oat beta-glucan 3%, [phenoxyethanol, ethylhexylglycerin] 0.8%, water 85.27%, microemulsion matrix 3% and plant extract 6%;

[0055] S2. The first weighing of raw materials: take a beaker, weigh the required PPG-5-cethyl polyether-20, oleth-3 phosphate and white pond flower seed oil in proportion and put them into the beaker In the process, the required raw materials are obtained and set aside;

[0056] S3, prepare phase A: heat the raw materials in the beaker in step S1 while mixing, after mixing evenly, obtain the required phase A, keep it warm for subsequent use;

[0057] S4, preparation of phase B: measure the required water and put it into a beaker, heat it, slowly add the heated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com