Recycling method of iron and steel multiple waste

A waste, multi-component technology, applied in the field of recycling and utilization of steel multi-component waste, can solve the problems of large floor space, ammonium sulfate crystal blockage, waste of sulfuric acid resources, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

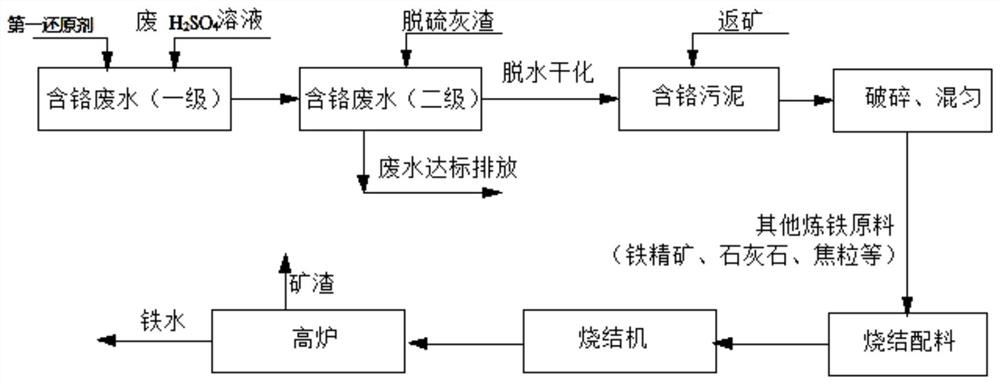

[0058] This embodiment discloses a recycling method for multiple iron and steel wastes, which includes the following specific processes:

[0059] (1) Take dilute sulfuric acid, a by-product of coking flue gas desulfurization, and add it to the chromium-containing wastewater to adjust the pH of the solution to 2 to 3; if the chromium-containing wastewater contains CrO 4 2- , then it transforms into Cr in acidic environment 2 o 7 2- ; The dilute sulfuric acid by-product of coking flue gas desulfurization contains 9.5% dilute sulfuric acid and 0.7% sulfurous acid in mass percentage.

[0060] (2) Cr in the solution obtained from step (1) 2 o 7 2- The molar concentration of 0.5mmol / L, first add the first reductant NaHSO in the solution obtained in step (1) 3 , add according to the standard of 1.2mmol / L, then add the sintered desulfurization ash according to the standard of 18g / L, the CaSO in the said sintered desulfurization ash 3 content of 270g / kg, f-CaO content of 150g / k...

Embodiment 2

[0066] This embodiment discloses a recycling method for multiple iron and steel wastes, which includes the following specific processes:

[0067] (1) Take dilute sulfuric acid, a by-product of coking flue gas desulfurization, and add it to the chromium-containing wastewater to adjust the pH of the solution to 2 to 3; if the chromium-containing wastewater contains CrO 4 2- , then it transforms into Cr in acidic environment 2 o 7 2- ; The coking flue gas desulfurization by-product dilute sulfuric acid contains 12.5% dilute sulfuric acid and 1.0% sulfurous acid in mass percent.

[0068] (2) Cr in the solution obtained from step (1) 2 o 7 2- The molar concentration of 0.75mmol / L is added to the solution obtained in step (1) according to the standard of 1.8mmol / L, and then the sintered desulfurization ash is added according to the standard of 27g / L, and the CaSO in the sintered desulfurization ash 3 content of 300g / kg, f-CaO content of 150g / kg to the solution Cr 2 o 7 2...

Embodiment 3

[0074] This embodiment discloses a recycling method for multiple iron and steel wastes, which includes the following specific processes:

[0075] (1) Take dilute sulfuric acid, a by-product of coking flue gas desulfurization, and add it to the chromium-containing wastewater to adjust the pH of the solution to 2 to 3; if the chromium-containing wastewater contains CrO 4 2- , then it transforms into Cr in acidic environment 2 o 7 2- ; The coking flue gas desulfurization by-product dilute sulfuric acid contains 15% dilute sulfuric acid and 1.2% sulfurous acid in mass percent.

[0076] (2) Cr in the solution obtained from step (1) 2 o 7 2- The molar concentration of 1.0mmol / L is added to the solution obtained in step (1) according to the standard of 2.4mmol / L, and then the sintered desulfurization ash is added according to the standard of 36g / L, and the CaSO in the sintered desulfurization ash 3 The content is 350g / kg, and the content of f-CaO is 250g / kg to Cr in the soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com