Low-gloss anaerobic biodegradable biaxially oriented polypropylene film

A polypropylene film, biodegradable technology, used in applications, household appliances, layered products, etc., can solve the problems of difficult decomposition of products, unrecyclable waste, soil pollution, etc., to achieve excellent performance, controllable service cycle, and manufacturing low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

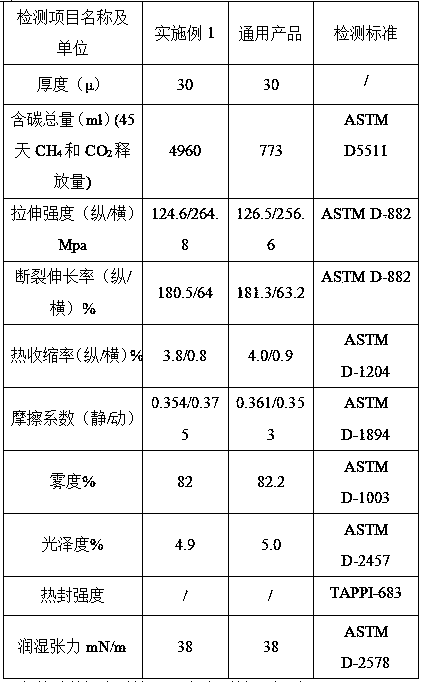

[0032] For the low-gloss anaerobic biodegradable biaxially oriented polypropylene film, the upper surface layer is selected from the components of 96.5% homopolypropylene, 2.5% AB6018PP anti-sticking agent, and 1.0% anaerobic biodegradation agent. Formed, and the melt index range of homopolypropylene is 2.6-3.2g / 10min. The core layer is made of components with weight percentages of 93% homopolypropylene, 3.0% antistatic agent, 3.0% slip agent, and 1.0% anaerobic biodegradation agent, and the melt index range of homopolypropylene is 2.6-3.2g / 10min. The antistatic agent is an alkylamine antistatic agent; the slip agent is an erucamide slip agent. The lower surface layer is made of components with a weight percentage of 99.0% matte material and 1.0% anaerobic biodegradant, and the melt index range of homopolypropylene is 2.6-3.2g / 10min. The thickness of the upper surface layer is controlled to be 1.0μ, the thickness of the core layer is controlled to be 26.5μ, and the thickness...

Embodiment 2

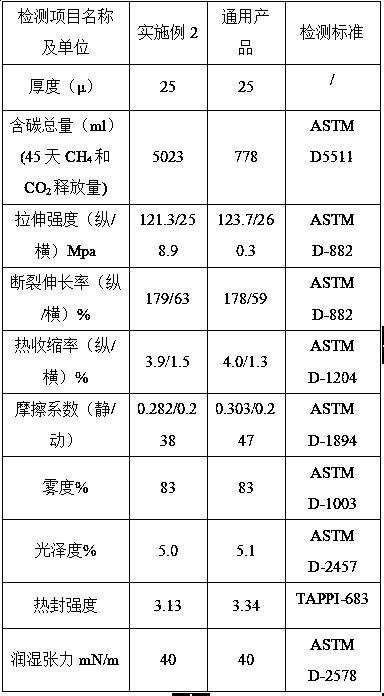

[0043]For the low-gloss anaerobic biodegradable biaxially oriented polypropylene single-sided heat-seal film, the upper surface layer is selected from 97.0% by weight of polypropylene copolymer, 2.0% of anti-sticking agent AB6018PPCPP, and 1.0% of anaerobic biodegradation agent. It is prepared from components, and the melt index range of copolymerized polypropylene is 3.0-6.0g / 10min. The core layer is made of components with weight percentages of 95% homopolypropylene, 2.0% antistatic agent, 2.0% slip agent, and 1.0% anaerobic biodegradation agent, and the melt index range of homopolypropylene is 2.6-3.2g / 10min. The antistatic agent is an alkylamine antistatic agent; the slip agent is an erucamide slip agent. The lower surface layer is made of components with a weight percentage of 99.0% matte material and 1.0% anaerobic biodegradant, and the melt index range of homopolypropylene is 2.6-3.2g / 10min. The thickness of the upper surface layer is controlled to be 1.0μ, the thickn...

Embodiment 3

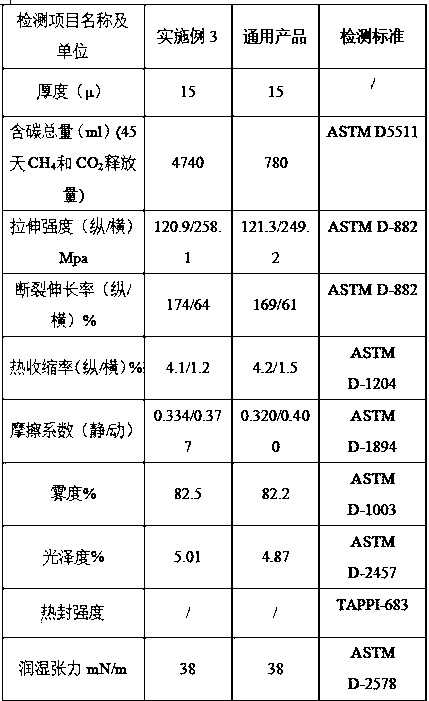

[0054] For the low-gloss anaerobic biodegradable biaxially oriented polypropylene film, the upper surface layer is selected from the components of 97.0% homopolypropylene, 2.0% AB6018PP anti-sticking agent, and 1.0% anaerobic biodegradation agent. Formed, and the melt index range of homopolypropylene is 2.6-3.2g / 10min. The core layer is made of components with weight percentages of 95% homopolypropylene, 2.0% antistatic agent, 2.0% slip agent, and 1.0% anaerobic biodegradation agent, and the melt index range of homopolypropylene is 2.6-3.2g / 10min. The antistatic agent is an alkylamine antistatic agent; the slip agent is an erucamide slip agent. The lower surface layer is made of components with a weight percentage of 99.0% matte material and 1.0% anaerobic biodegradant, and the melt index range of homopolypropylene is 2.6-3.2g / 10min. And the thickness of the upper surface layer is controlled to be 1.0 μ, the thickness of the core layer is controlled to be 11.0 μ, and the thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com