High-temperature absorbent and preparation method thereof, and ultrathin high-temperature wave-absorbing material and preparation method thereof

A technology of absorbing material and absorbing agent, applied in chemical instruments and methods, other chemical processes, inorganic chemistry, etc., can solve the problems of large thickness and large thickness of absorbing materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

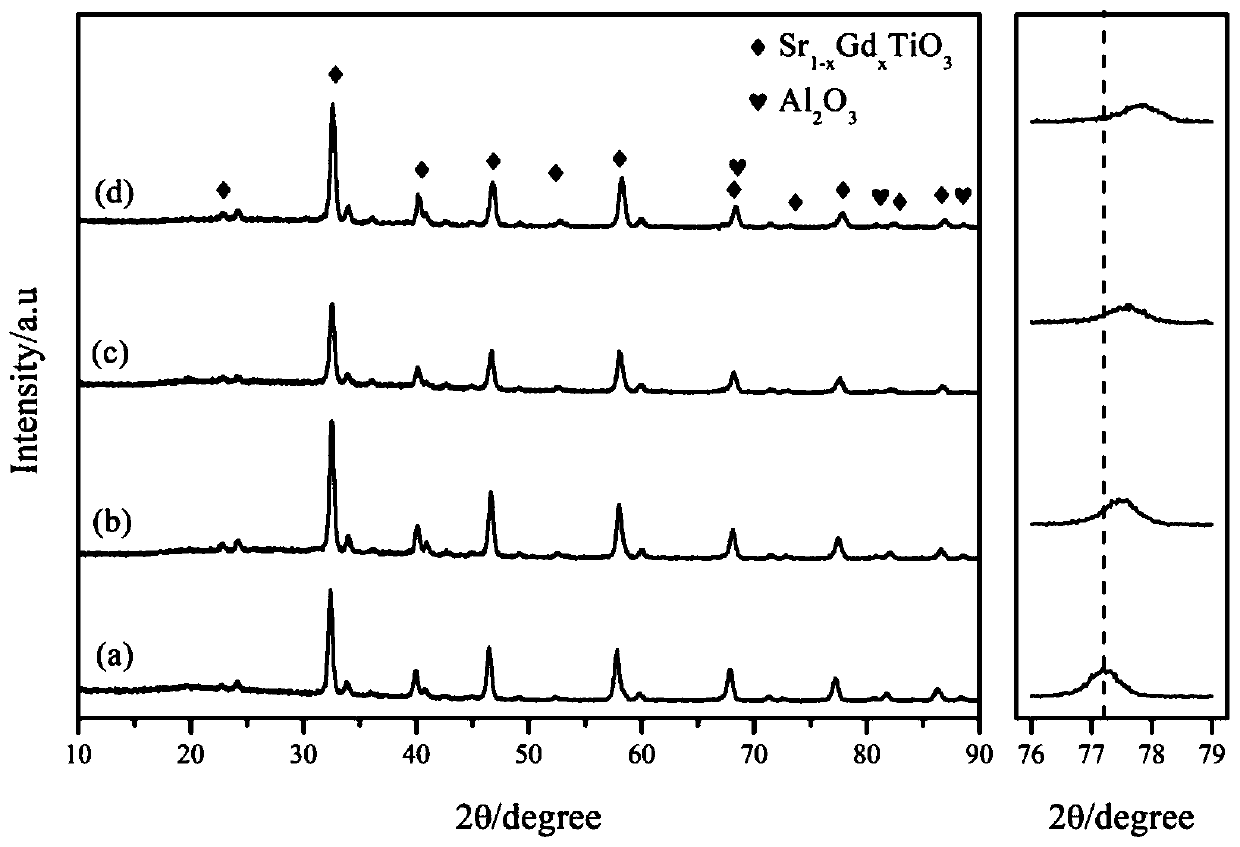

Embodiment 1

[0053] This embodiment proposes an ultra-thin high-temperature wave-absorbing material made of titanium dioxide (TiO 2 ), strontium carbonate (SrCO 3 ), gadolinium oxide (Gd 2 o 3 ) and alumina (Al 2 o 3 ) composition, among them, TiO 2 , SrCO 3 and Al 2 o 3 All are analytically pure, Gd 2 o 3 The purity is greater than or equal to 99.999%.

[0054] This embodiment also proposes a method for preparing the ultra-thin high-temperature wave-absorbing material, the specific process is:

[0055] The first step is to prepare Sr 1-x Gd x TiO 3 Absorbent, where x=0.05:

[0056] (1) Weighing: Weigh TiO according to the stoichiometric ratio of 1:0.95:0.025 2 , SrCO 3 and Gd 2 o 3 .

[0057] (2), ball milling: the weighed TiO 2 , SrCO 3 and Gd 2 o 3 Pour into a stainless steel ball mill jar, and add stainless steel grinding balls, stainless steel grinding balls and TiO 2 and SrCO 3 The ball-to-material ratio of the mixed material is 20:1; add absolute ethanol to ...

Embodiment 2

[0069] This embodiment proposes an ultra-thin high-temperature wave-absorbing material made of titanium dioxide (TiO 2 ), strontium carbonate (SrCO 3 ), gadolinium oxide (Gd 2 o 3 ) and alumina (Al 2 o 3 )composition. Among them, TiO 2 , SrCO 3 and Al 2 o 3 All are analytically pure, Gd 2 o 3 The purity is greater than or equal to 99.999%.

[0070] This embodiment also proposes a method for preparing the ultra-thin high-temperature wave-absorbing material, the specific process is:

[0071] The first step, preparation of Sr 1-x Gd x TiO 3 Absorbent, where x=0.1:

[0072] (1) Weighing: Weigh TiO according to the stoichiometric ratio of 1:0.9:0.05 2 , SrCO 3 and Gd 2 o 3 .

[0073] (2), ball milling: the weighed TiO 2 , SrCO 3 and Gd 2 o 3 Pour into a nylon ball mill jar, and add zirconia balls, zirconia balls and TiO 2 , SrCO 3 and Gd 2 o 3 The ball-to-material ratio of the mixed material is 25:1; add absolute ethanol to submerge the TiO 2 , SrCO 3 ...

Embodiment 3

[0085] This embodiment proposes an ultra-thin high-temperature wave-absorbing material made of titanium dioxide (TiO 2 ), strontium carbonate (SrCO 3 ), gadolinium oxide (Gd 2 o 3 ) and alumina (Al 2 o 3 )composition. Among them, TiO 2 , SrCO 3 and Al 2 o 3 All are analytically pure, Gd 2 o 3 The purity is greater than or equal to 99.999%.

[0086] This embodiment also proposes a method for preparing the ultra-thin high-temperature wave-absorbing material, the specific process is:

[0087] The first step, preparation of Sr 1-x Gd x TiO 3 Absorbent, where x=0.2:

[0088] (1) Weighing: Weigh TiO according to the stoichiometric ratio of 1:0.8:0.1 2 , SrCO 3 and Gd 2 o 3 .

[0089] (2), ball milling: the weighed TiO 2 , SrCO 3 and Gd 2 o 3 Pour into the zirconia ball mill jar, and add zirconia balls, zirconia balls and TiO 2 , SrCO 3 and Gd 2 o 3 The ball-to-material ratio of the mixed material is 30:1; add absolute ethanol to submerge the TiO 2 , SrCO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| absorption bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com