Novel tunnel advanced small guide pipe, advanced support system and construction method

An advanced small conduit and tunnel technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as failure to reach design pressure, influence on construction organization arrangements, and inability to spread and solidify grout, so as to ensure construction safety and avoid encirclement. Rock deformation hard to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

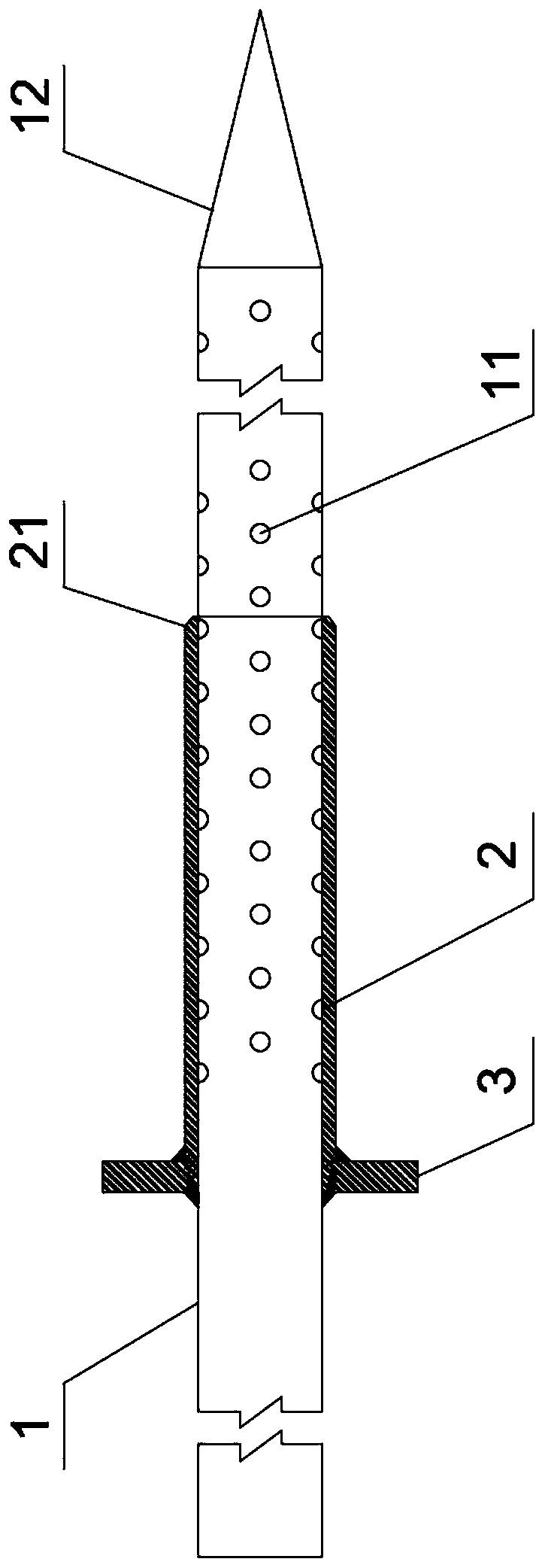

[0029] see figure 1 As shown, the embodiment of the present invention provides a new type of tunnel leading small catheter, which includes a catheter body 1 and a sleeve 2. One end of the catheter body 1 is provided with a grouting port, and the other end is provided with a number of grouting holes 11. The sleeve 2 is fixed. Located outside the conduit body 1 , the sleeve 2 covers a part of the grouting holes 11 , and another part of the grouting holes 11 is located on the side of the sleeve 2 away from the grouting port.

[0030] The casing 2 provided can close the grouting hole 11 that is not inserted into the surrounding rock, so as to avoid the situation of grout leakage when using the advanced small conduit for grouting operation, resulting in the insufficient grouting pressure in the surrounding rock. When the design pressure is reached...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com