An intelligent cleaning, peeling and seeding system for wine making

A smart cleaning and wine technology, applied in applications, fruit pitting devices, vegetable or fruit peeling, etc., can solve problems such as excessive volume, affecting the fermentation process, and increasing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

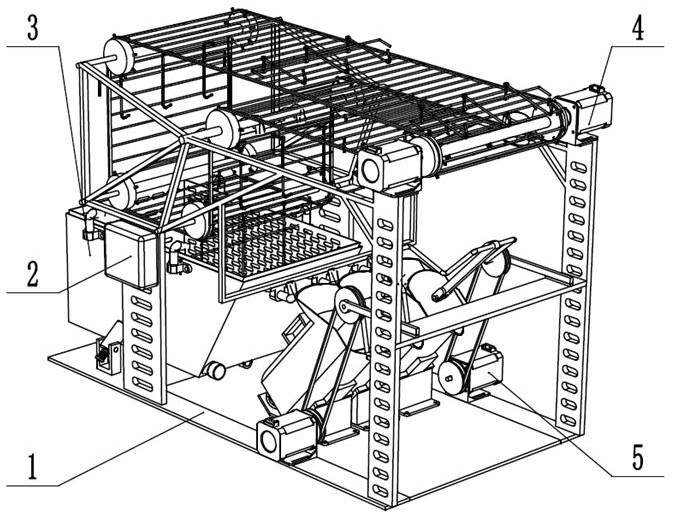

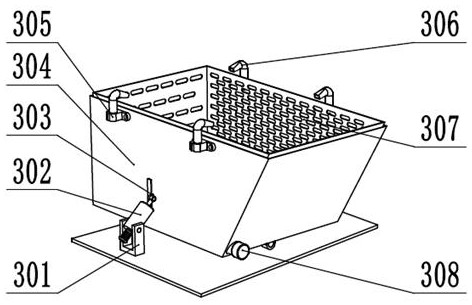

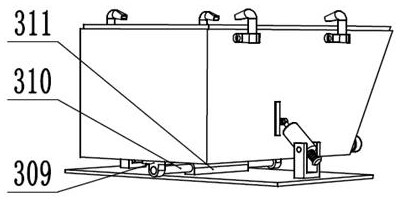

[0018] Example figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7The shown intelligent cleaning, peeling and seeding system for wine making includes a base 1, an electric control box 2, a cleaning mechanism 3, a transfer chain mechanism 4, and a peeling and seeding mechanism 5. The base 1 is a rectangular platform, close to two There are two sets of stands on the edge of the long side, which are used to fix the transfer chain mechanism 4 and the electric control box 2. The cleaning mechanism 3 and the peeling and seeding mechanism 5 are directly placed on the rectangular platform of the base 1. The cleaning mechanism 3 includes two Exciting electromagnet bracket 301, two exciting e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com