Electro-pneumatic brake control device and brake control system

A technology of electro-pneumatic braking and control devices, applied in the direction of braking transmission devices, brakes, pneumatic brakes, etc., can solve the problems of rolling stock and line damage, endangering driving safety, broken hooks, etc., to reduce damage and reduce impact force , improve the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

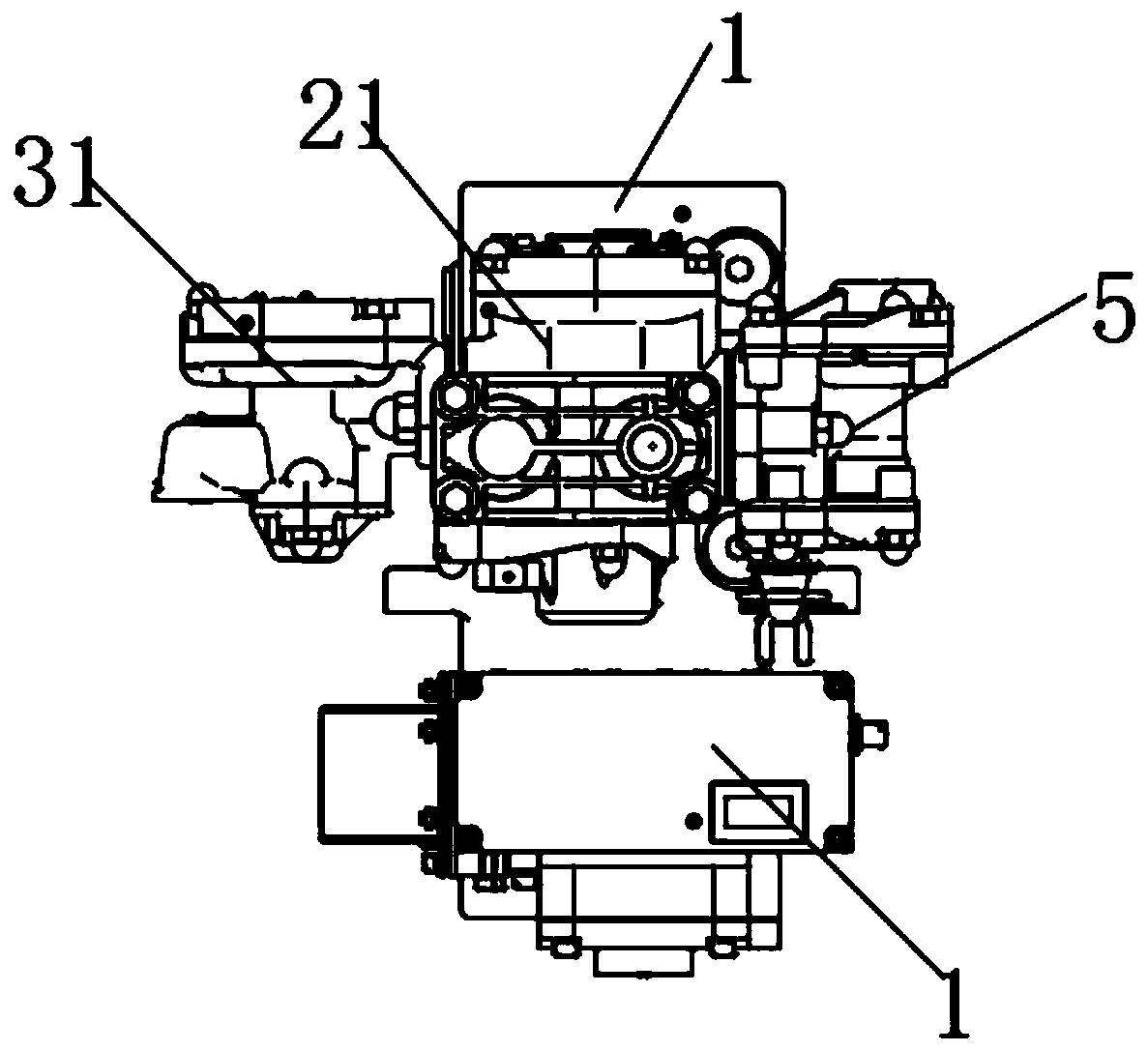

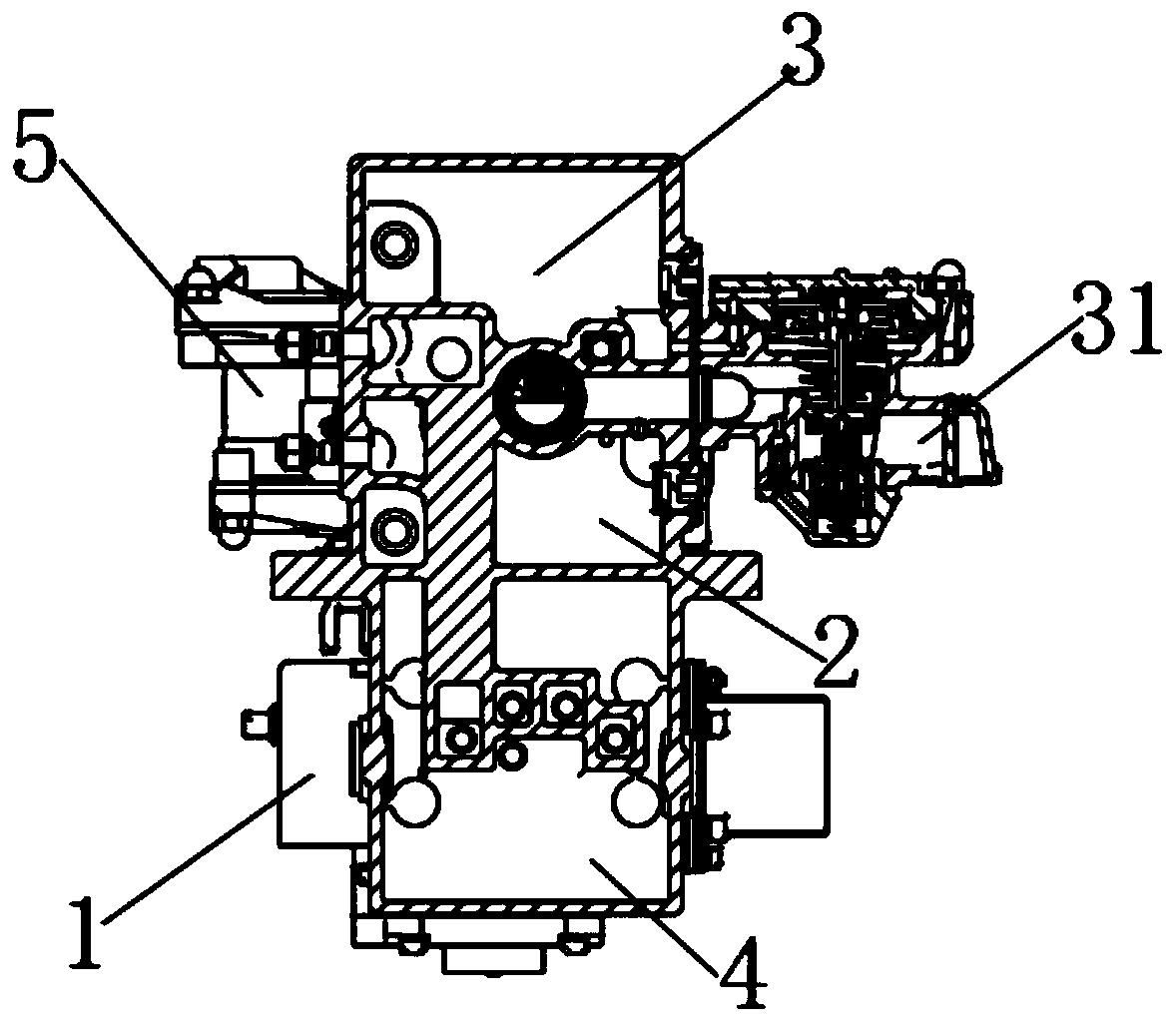

[0027] Such as figure 1 , figure 2 , image 3 As shown, in this embodiment, a control device for electropneumatic braking includes an intermediate body and a control unit installed on the intermediate body;

[0028] The intermediate body includes a mounting seat 1 and a pre-control chamber 4 arranged in the mounting seat 1, and the control unit communicates with the pre-control chamber 4;

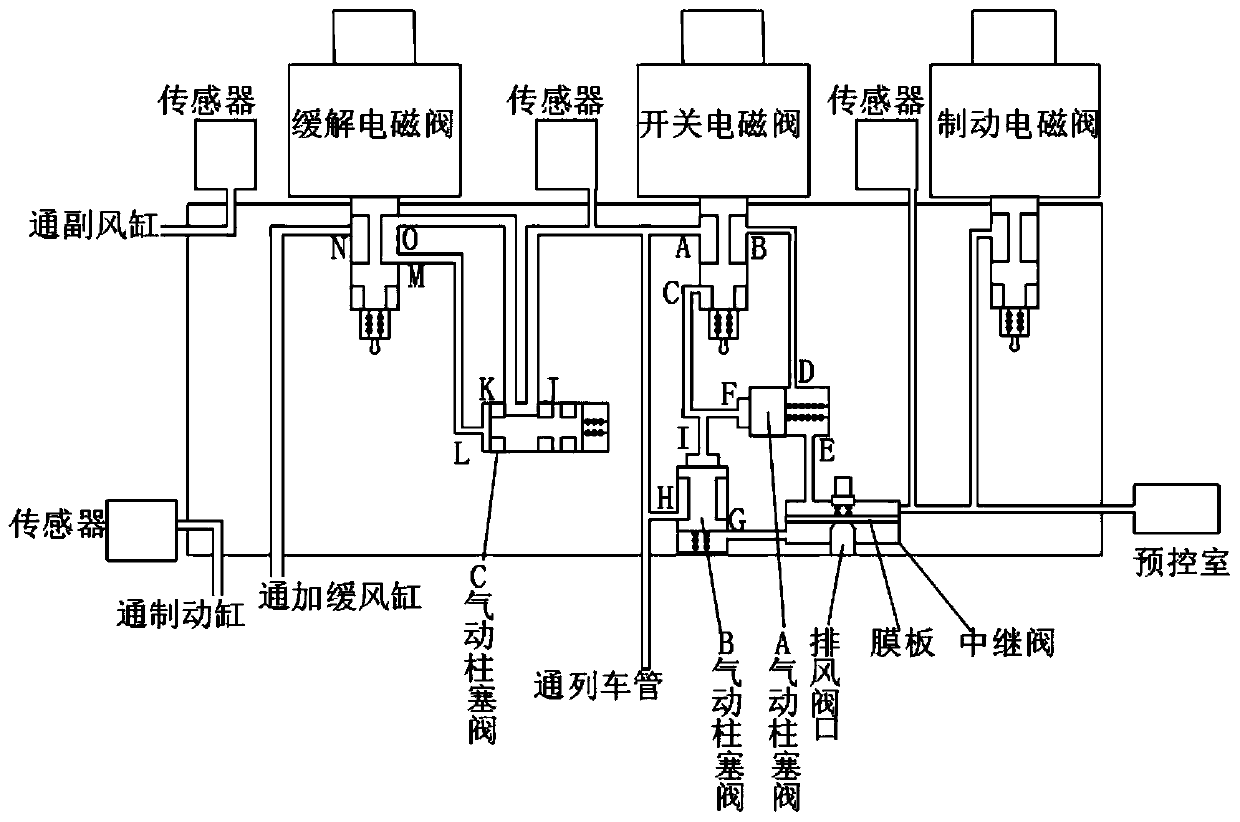

[0029] The control unit includes an on-off solenoid valve connected to the train pipe through port C, a pneumatic plunger valve A connected to port B of the switch solenoid valve A through port D, and an intermediate valve connected to the E port of the pneumatic plunger valve A through the upper space of the membrane plate. The relay valve and the pre-control chamber arranged in the intermediate body and communicated with the upper space of the membrane plate; the lower space of the relay valve diaphragm communicates with the train pipe; the F port of the A pneumatic plunger valve commu...

Embodiment 2

[0043] On the basis of the above embodiments, in this embodiment, the space below the diaphragm of the relay valve communicates with the G port of the B pneumatic plunger valve, and the H port of the B pneumatic plunger valve communicates with the train pipe. The I port of the B pneumatic plunger valve is connected with the F port of the A pneumatic plunger valve.

[0044] When the switch solenoid valve is de-energized, use the B pneumatic plunger valve to cut off the space under the train pipe and the membrane plate, so as to avoid the air exhaust of the train pipe due to the poor sealing of the exhaust valve port.

[0045]When the switch solenoid valve is energized, port A is connected to port C, and the pressure air of the train pipe enters the pneumatic plunger valve of B through port C and port I to push the plunger in the pneumatic plunger valve of B to move, making port H It is connected with port G, even if the space under the diaphragm is connected with the train pipe...

Embodiment 3

[0047] On the basis of the above embodiments, in this embodiment, the outlet is a brake solenoid valve connected to the air path between the relay valve and the pre-control chamber. Using the solenoid valve as the discharge outlet of the pressure air in the pre-control room can also realize the function of remote electric control, thereby improving the response speed of the control and improving the braking efficiency. In this embodiment, the gas path between the relay valve and the pre-control chamber is connected with a sensor. The use of sensors is conducive to real-time monitoring of pressure changes in the pre-control chamber, thereby facilitating real-time control of pressure changes in the pre-control chamber and improving control accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com