Industrial-preservative-free green tea fragrance cigarette paper, and preparation method thereof

A green tea fragrance and cigarette paper technology, applied in paper, papermaking, textiles and papermaking, etc., can solve the problems of uneven fragrance release, high production cost, complicated process, etc., achieve full smell, moderate strength, and reduce nicotine content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

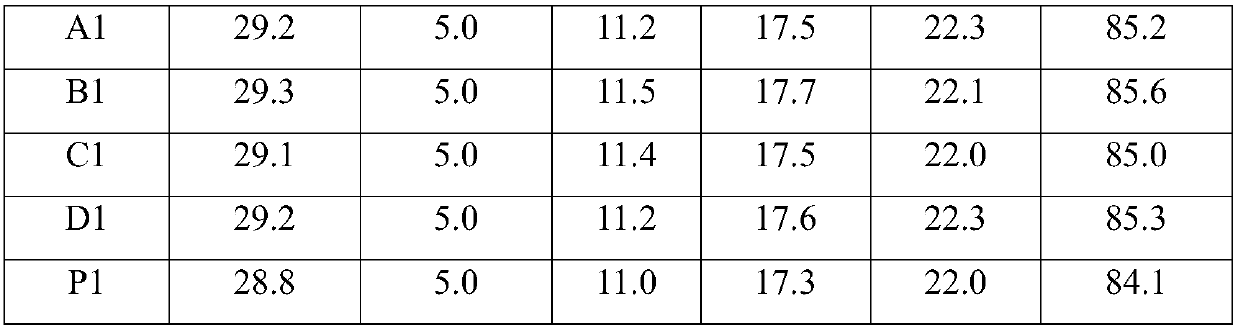

Embodiment 1

[0045] A Longjing green tea scented cigarette paper without industrial preservatives, comprising Longjing green tea, wood papermaking raw materials and additives, the mass fractions of each component are: Longjing green tea: 20%, wood papermaking raw materials: 75%, additives: 5%, Wherein the mass percent of each component of additive is calcium carbonate mixture: 96.77% (wherein calcium carbonate 70%, magnesium hydroxide 30%), the preservative preparation 2% that green tea extracts, combustion aid: 1%, defoamer: 0.2%, Enhancer: 0.8%.

[0046] The preparation method of above-mentioned Longjing green tea fragrant cigarette paper, concrete steps are:

[0047] 1) Pulp preparation

[0048] Weigh 20kg of Longjing green tea and 75kg of wood and papermaking raw materials, add water to Longjing green tea and beat to obtain the first material, add water to the wood and papermaking raw materials to obtain a second material, mix the first and second materials, and mix the obtained mixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com