High-power device heat dissipation device and method

A technology of high-power devices and heat dissipation devices, which is applied to the heat dissipation of high-power devices on aerospace vehicles. In the field of aerospace, it can solve the problems that cannot meet the heat dissipation requirements of high-power devices, so as to prevent high-temperature failures, increase heat dissipation paths, and ensure normal working effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

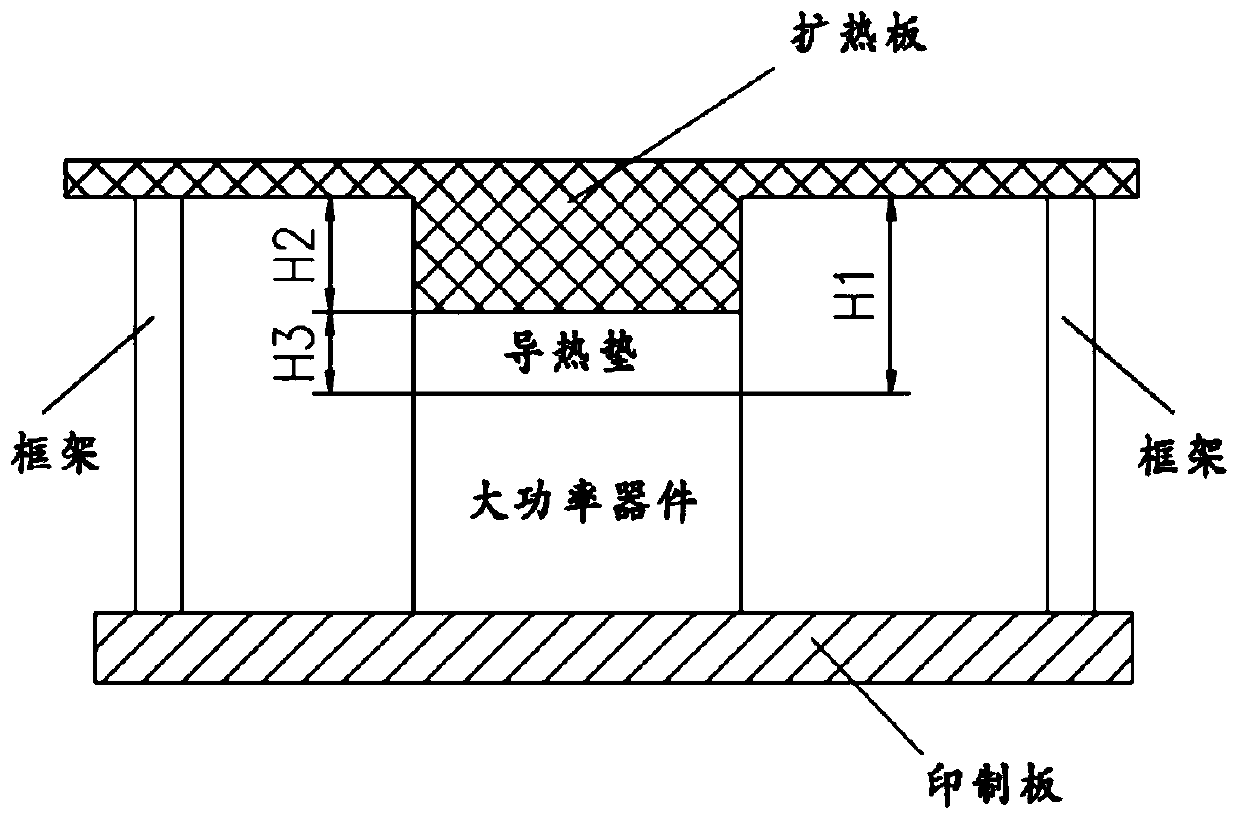

[0044] like figure 1 As shown, a heat dissipation method for a high-power device, the bottom of the high-power device is welded on the printed board through welding legs, the top of the high-power device is connected to the graphite heat spreader through the heat conduction pad, and the graphite heat spreader is fixedly connected to the frame , and the connection position between the frame and the graphite heat expansion plate has a heat conduction boss, the height of the heat conduction boss is 8-10mm, the graphite heat expansion plate is fixedly connected to the heat conduction boss of the frame through thermal grease, and the frame is fixedly connected to the cold plate; heat conduction The thickness of the pad is 0.4-0.5mm; there is a boss at the connection position between the graphite heat expansion plate and the heat conduction pad, and GD-414 glue is applied between the boss on the graphite heat spreader and the heat conduction pad.

[0045] First paste one side of the...

Embodiment 2

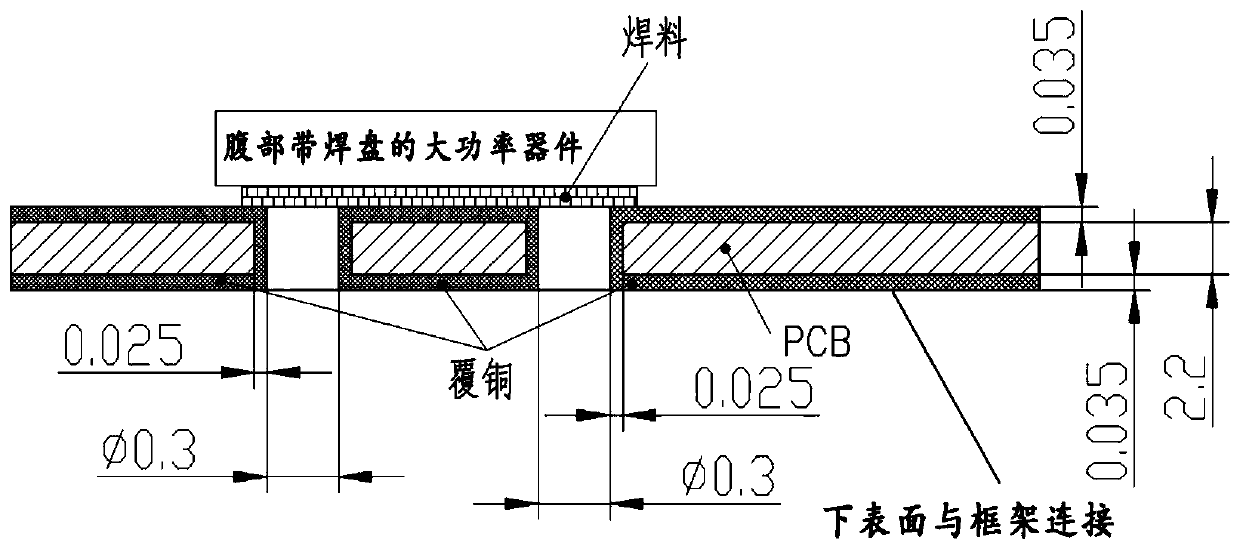

[0047] like figure 2 As shown, a heat dissipation method for high-power devices, the upper surface of the printed board is connected to the high-power device, the lower surface of the printed board is connected to the frame, and the connection between the upper surface of the printed board and the high-power device is coated with copper There are several through holes in the connecting part of the printed board and the high-power device. The inner surfaces of the several through holes are coated with a copper layer. The thickness of the copper layer is 0.025mm. The bottom of the high-power device is welded through the belly The disk is welded on the printed board; the diameter of the through hole is 0.2-0.3mm, and the number of the through hole is 20-30.

[0048] A method for dissipating heat from a high-power device, the steps of the method comprising:

[0049] (1) Process several through holes on the printed board;

[0050] (2) coating copper layer on the inner surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com