A uniform wind structure of a heat exchanger

A technology of heat exchanger and hot air inlet, applied in the field of drying clothes, can solve the problems of small contact area between steam and condenser, high manufacturing cost of aluminum alloy material, uneven air intake of condensation structure, etc., so as to improve heat exchange efficiency and reduce The failure repair rate and the effect of increasing the contact heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

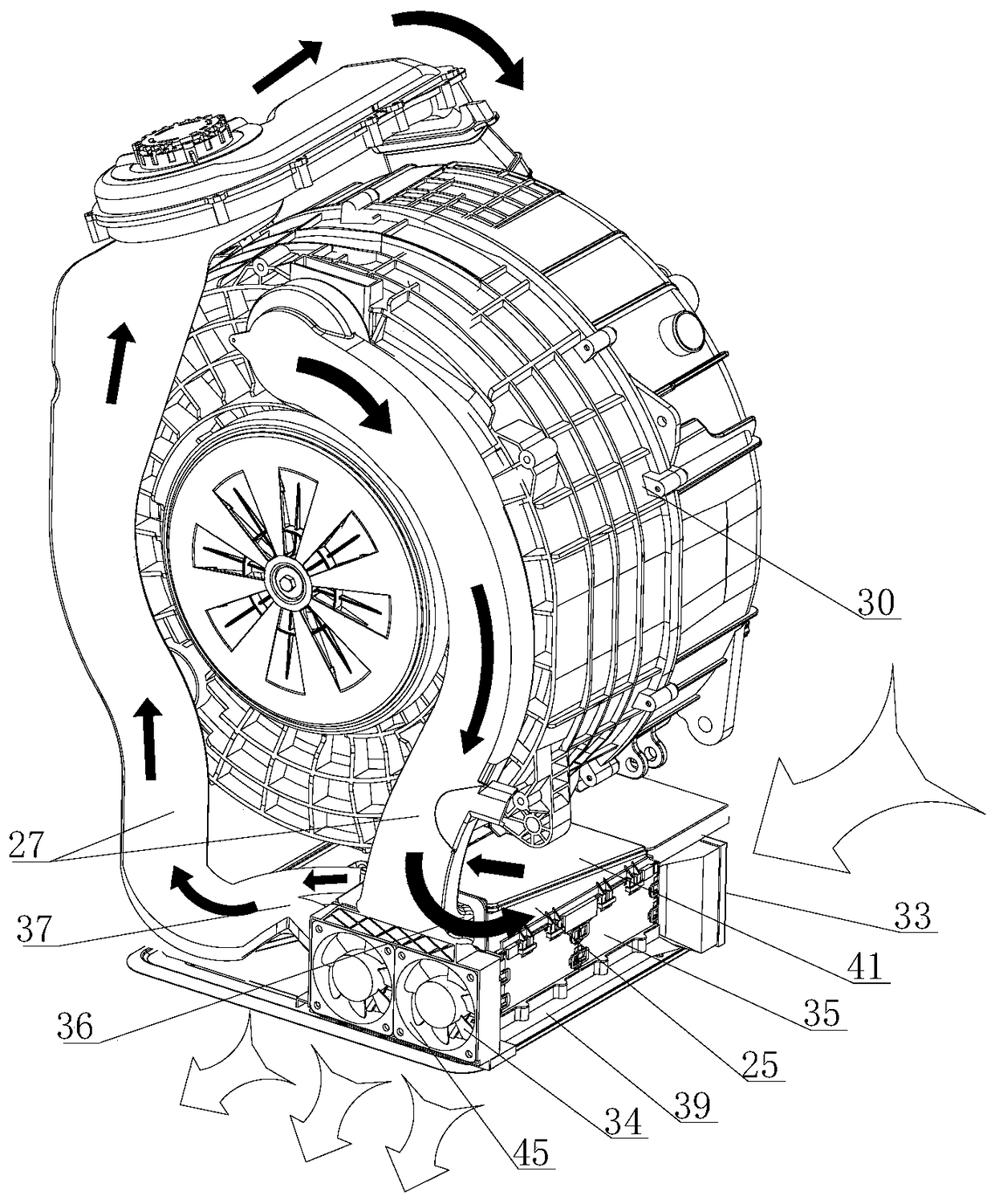

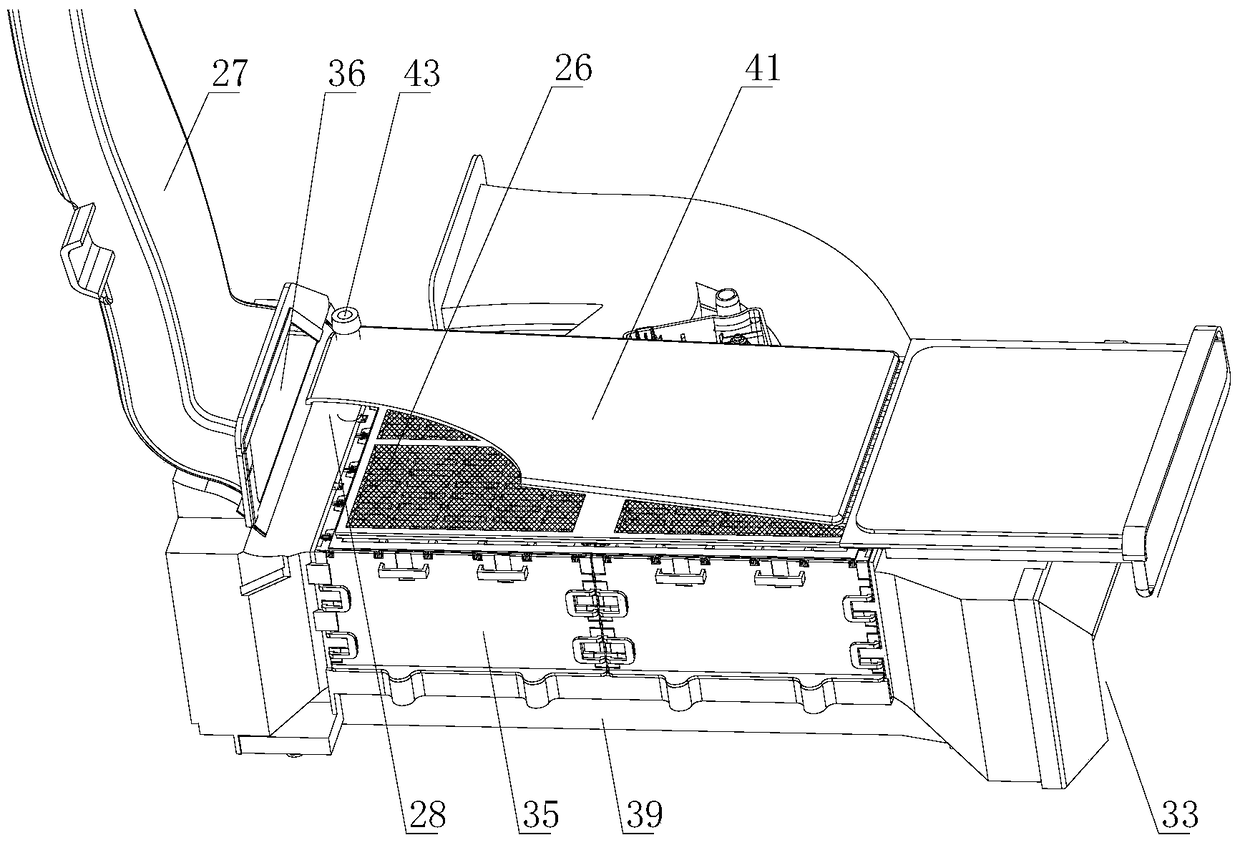

[0041] According to the air uniform structure of the heat exchanger in the present invention, the heat exchanger includes two sets of intersecting air paths, one set of air paths is connected with the hot air path, and the other set of air paths is connected with the cold air path. The hot air inlet of the heat exchanger is provided with an air-in uniform structure, and / or the hot air outlet of the heat exchanger is provided with an air-even air structure, which can guide the airflow to enter and discharge evenly, avoid unevenness of hot air, and improve heat transfer. The efficiency, on the other hand, avoids the uneven pressure caused by the uneven air flow, which will affect the system.

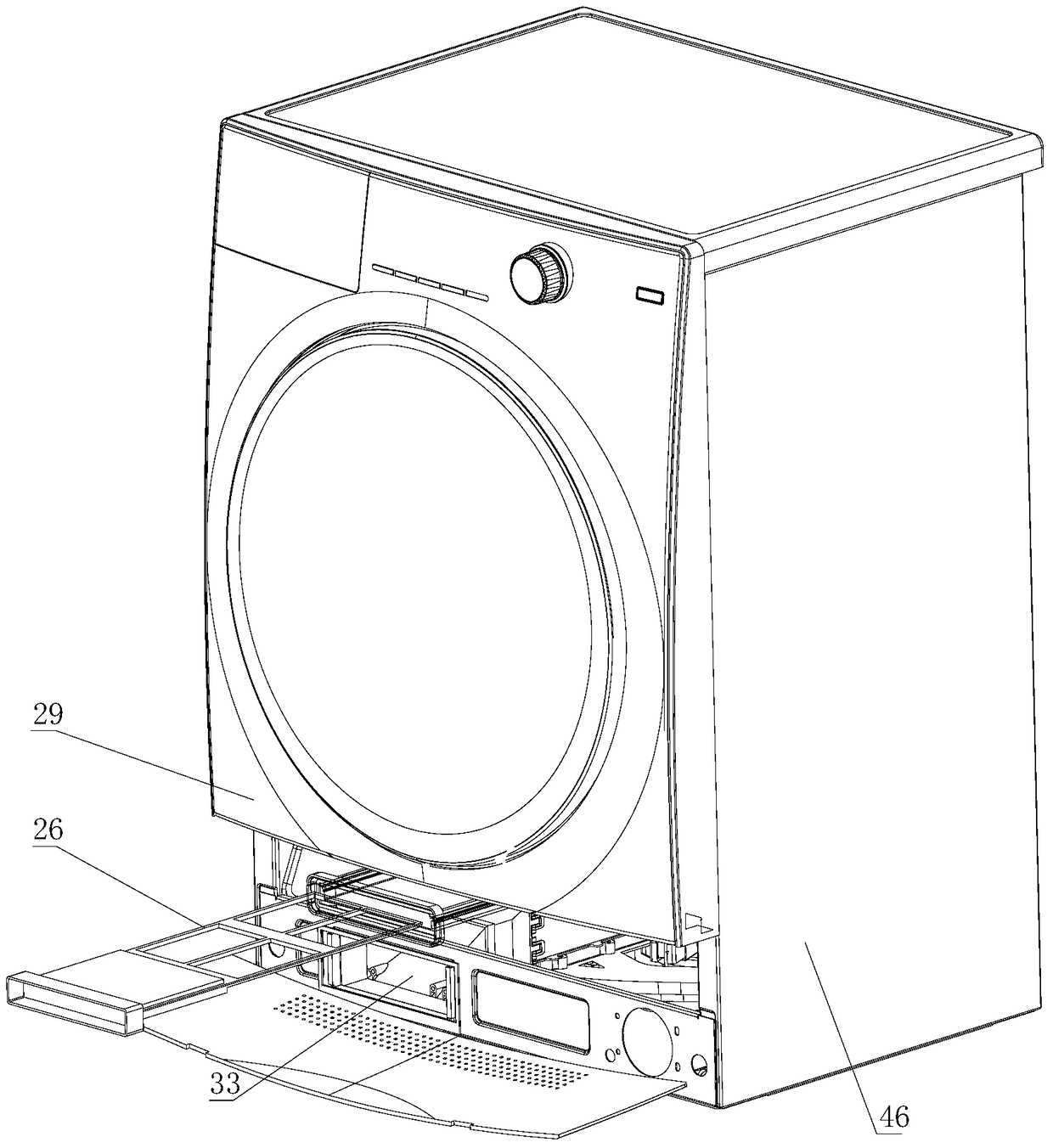

[0042] Such as Figure 14 , Figure 15 , Figure 16 As shown, the wind uniform structure of the air inlet is as follows: an upper cover plate 25 is arranged at the hot air inlet 24 of the exchanger, and the upper cover plate 25 has an inclined top surface, and the upper cover plate 25 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com