Cultivation method of sympodial bamboos used for producing high-cellulose-content fibers

A technology of high cellulose and cultivation method, applied in the field of clumping bamboo cultivation for fiber with high cellulose content, can solve the problems of lack of high-yield and high-quality directional cultivation technology, poor quality, low yield, etc., achieve directional cultivation and improve stability Sexuality and fast growth of bamboo

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

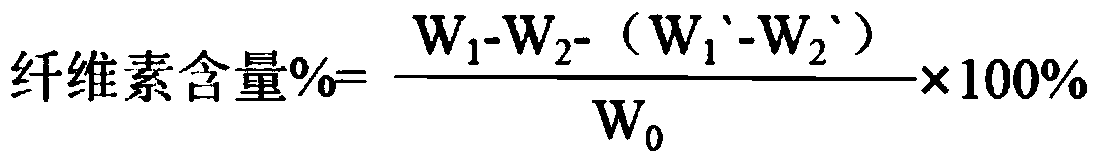

Method used

Image

Examples

Embodiment 1

[0019] A method for cultivating clump bamboo for producing fibers with high cellulose content, comprising the following steps:

[0020] Step 1, preparation is used for regulating and controlling the composite solution of clustered bamboo cellulose content, and the concentration of each component of described composite solution is: polypeptide urea 15mg / L, gibberellin GA 3 5mg / L, diethyl hexanoate 20mL / L, potassium dihydrogen phosphate 100mg / L, Zn(NO 3 ) 2 EDTA 10mg / L, sodium molybdate 0.15mg / L, MgSO 4 ·7H 2 050mg / L, the pH of composite solution is 6.5;

[0021] Step 2, select the fiber-used bamboo forest soil with the same growth and soil type, and adjust the basic fertility of the soil to be hydrolyzable nitrogen 320mg / kg, available potassium 260mg / kg, and available phosphorus 25mg / kg through fertilization; plant 40 clumps of bamboos per mu of land , the distance between plants and rows is 4ⅹ4m, and 15 1-year-old bamboos are reserved for each clump of Cizhu;

[0022] St...

Embodiment 2

[0025] A method for cultivating clump bamboo for producing fibers with high cellulose content, comprising the following steps:

[0026] Step 1, preparation is used for regulating and controlling the composite solution of clustering bamboo cellulose content, and the concentration of each component of described composite solution is: polypeptide urea 18mg / L, gibberellin GA 3 10mg / L, diethyl hexanoate 20mL / L, potassium dihydrogen phosphate 100mg / L, Zn(NO 3 ) 2 EDTA 10mg / L, sodium molybdate 0.15mg / L, MgSO 4 ·7H 2 050mg / L, the pH of composite solution is 6.5;

[0027] Step 2, choose the Liangshan Cizhu bamboo forest soil with the same growth and soil type, and adjust the basic fertility of the soil by fertilization to be 320 mg / kg of hydrolyzable nitrogen, 260 mg / kg of available potassium, and 25 mg / kg of available phosphorus; plant 40 per mu of land Congliangshan Cizhu, the spacing between plants and rows is 4ⅹ4m, and 15 1-year-old bamboos are reserved for each cluster;

[0...

Embodiment 3

[0031] A method for cultivating clump bamboo for producing fibers with high cellulose content, comprising the following steps:

[0032]Step 1, preparation is used for regulating and controlling the composite solution of clustered bamboo cellulose content, and the concentration of each component of described composite solution is: polypeptide urea 5mg / L, gibberellin GA 3 13mg / L, diethyl hexanoate 20mL / L, potassium dihydrogen phosphate 100mg / L, Zn(NO 3 ) 2 EDTA 10mg / L, sodium molybdate 0.15mg / L, MgSO 4 ·7H 2 050mg / L, the pH of composite solution is 6.5;

[0033] Step 2, select the fiber green bamboo forest soil with the same growth and soil type, and adjust the basic fertility of the soil by fertilization to be 320 mg / kg of hydrolyzable nitrogen, 260 mg / kg of available potassium, and 25 mg / kg of available phosphorus; plant 40 bushes per mu of land For green bamboo, the spacing between plants and rows is 4ⅹ4m, and 15 1-year-old bamboos are reserved for each clump;

[0034] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com